High potential near-miss: Damage to small boat during offshore survey operations

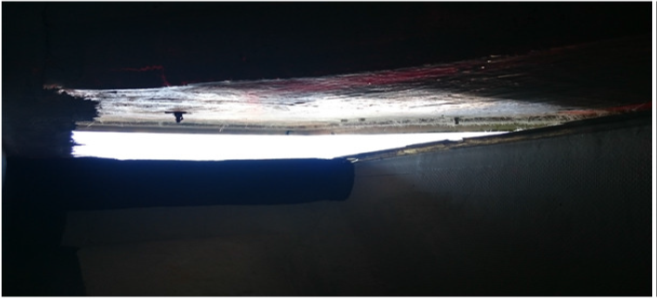

A member has reported an incident in which a small boat was damaged during offshore survey operations. The incident occurred during offshore transit to port. The boat experienced a ‘following wave’ that overtook it, causing the boat to drop into the trough of the next wave, causing the foredeck to partially detach from the hull.

The Helmsman immediately stopped the boat and turned the stern into the waves to reduce any further water ingress. The crew activated the ’emergency response plan’ and performed an immediate inspection of the damage. Due to the potential for further water ingress, the Helmsman altered course and the boat was routed to the nearest port in liaison with the local coastguard.

Our member’s investigation revealed the following:

- The foredeck and the hull section was insufficiently bonded together when the boat was built in 2011. A detailed analysis indicated that: . Less than 10% of the bonding surfaces showed signs of aggravated rupture by splintering or de-lamination, indicating that they were incorrectly bonded at build stage . The GRP (glass-reinforced plastic or fibre-glass) bonding was likely to have been incorrectly performed due to the restricted space available in the foredeck . The vessel had undergone a competent and third party inspection that had concluded that no structural defects were identified in the GRP construction.The cause of the incident was found to be a material failure of the hull as a result of insufficient bonding during the build phase of the vessel. Whilst the weather, as with most marine operations, was an influence, this was not a major contributing factor given that hull designs of this nature should be able to operate under the experienced conditions.Our member took the following actions:

- Plan and implement better QC for bonding processes during construction of these boats;

- Planned regular Inspections for significant indicators (cracks in secondary internal bonding) to be included in maintenance routines;

- This particular boat underwent additional bonding and stiffening processes and was subjected to both marine and authority assessments before it was returned to operations;

- Further careful checking and verifying of the competence of third-party inspectors who carry out vessel surveys. Crews, owners, charterers and auditors need to be able to satisfy themselves that these surveys are carried out to the highest standard.

Further information on construction standards for small boats can be found at seafish.org/industry-support/marine-survey/construction-standards

Safety Event

Published: 27 June 2016

Download: IMCA SF 16/16

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.