Diver loss of consciousness during underwater burning activities

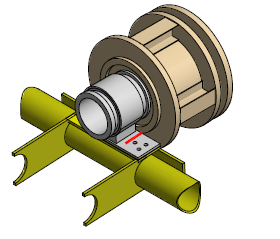

A member has reported an incident in which a diver lost consciousness during underwater burning activities. The incident occurred during decommissioning and removal of a subsea structure. Originally planned to be completed using cold cutting techniques, issues were experienced when attempting to remove the flowline towhead within the structure using cold cutting techniques. Bolts and gusset plates on the securing collar were understood to be preventing removal of the towhead. A management of change (MoC) and a specific risk assessment (SRA) for underwater burning operations was conducted, to assess the risks in burning these bolts and gusset plates.

Following this risk assessment, the removal of the bolts, gusset plates and other cuts were completed successfully and without incident using burning equipment. The diver was nearing completion of the final horizontal cut on the securing collar doubler plate when a suspected ‘blow back’ occurred. This ‘blow back’ is believed to have caused the diver to lose consciousness.

Our members’ investigation revealed the following:

- The initial task, which was risk assessed, ultimately changed. As the task evolved this change was not recognised and the job was not stopped and re-assessed.

- There was a perception that the scope of work and associated risks had not actually changed – the additional burning required was not recognised as change and the job was not stopped and re-assessed;

- The SRA was not collectively reviewed by the offshore team conducting the task. Some control measures within the risk assessment were not adhered to;

- The company procedure for burning operations and use of burning equipment was not fully complied with;

- The diver and dive supervisor were experienced in burning operations; however, it is an activity which no longer commonly takes place;

- The engineers responsible for the development of the procedures had limited experience in underwater burning operations;

- The immediate cause was believed to be a build-up of gas in a location within the doubler plate and structure, which had not been identified in the risk assessment or procedure as a hazard. As the investigation remains ongoing, the root cause of the incident cannot be fully determined until the structure has been recovered to surface and assessed further.

Our member drew the following lessons from the incident:

- This incident highlighted challenges regarding necessary competencies for underwater burning operations. As this methodology is not widely used everywhere, it can be a challenge to maintain the required level of competency;

- Decommissioning, particularly of older assets, is becoming more prevalent and presents additional hazards not routinely encountered during IRM or construction activities;

- Consulting detailed as-found surveys before the development of engineering procedures for decommissioning may prove a good use of time and effort. This will allow for early identification of potential hazards and will assist in the identification and implementation of the appropriate mitigations to manage the risks presented;

- The importance of being able to verify that personnel are fully aware of, understand and are able to follow company procedures.

Our member took the following actions:

- Suspended underwater burning operations until the root cause of this incident has been fully determined and a programme established and verified to ensure all lessons learned/actions from this incident have been met;

- Assessment of the company systems and processes for:

- assurance of competency of personnel

- effective MoC

- identification and adequate control of risk

- ensuring personnel comply with company process and procedures;

- Thorough review of dive project plans and scope of work procedures;

- Verification with client of ‘As Built’/’As Found’ information and data;

- A review of the operational MoC and SRA process to determine opportunities for improvement in relation to the timeline of this specific incident.

Our member notes that experience has shown that we should ‘expect the unexpected’ in decommissioning operations, and that therefore the MoC process becomes even more critical.

Members may wish to refer to the following incident (search words: diver, blowback):

Safety Event

Published: 22 November 2016

Download: IMCA SF 31/16

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.