LTI: Crush injury to middle and index finger

What happened

Riggers on a vessel were moving heavy deck plates (2.45 m x 1.2 m x 5 mm, weighing 114 kg) when one of them got his hand caught, causing a crush injury. The riggers were tasked with cleaning an area on the vessel. To do this, they had to lift the deck plates, degrease the deck below and power wash from the suspended deck above. During the task, it was noted that the debris and corrosion on the deck below would require shot blasting. A management decision was made to remove all the deck plates and stack them against handrails in preparation for this work.

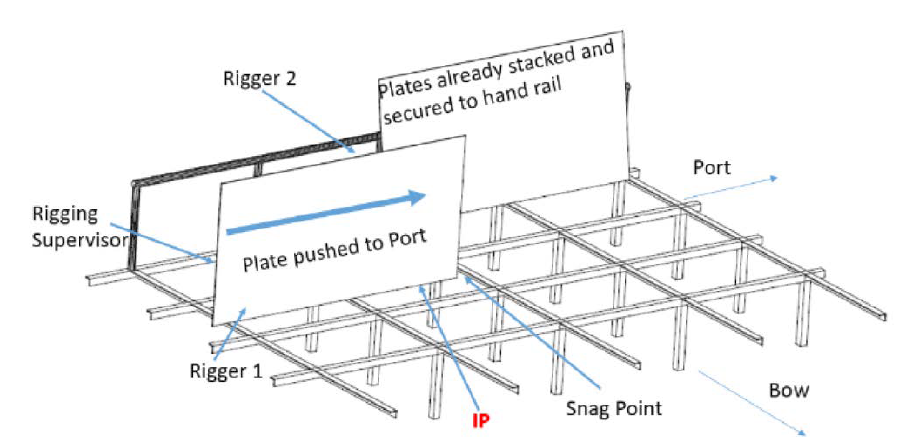

While moving one of the plates and turning it through 90Ëš onto its long axis, to be slid over the angle beam foundation, the leading corner of the plate caught on a section of angle beam and stopped sliding. A rigger (the IP in the sketch below) attempted to rectify this by lifting the corner, enabling the rest of the team to push the deck plate. Upon setting down the deck plate, his middle and index finger became trapped between the angle beam foundation and the deck plate, causing a serious injury.

What went wrong/causes

- The incident occurred as a result of ‘scope creep’. There was no proper Management of Change;

- The size and weight of the deck plates did not allow for a safe and ergonomically friendly means of moving them, especially over the angle beam foundation;

- The injured person placed his hand beneath the deck plate despite being instructed not to do so by his supervisor;

- The injured person was wearing welding gloves, rather than the impact gloves required in the JRA (job risk analysis);

- Pinch points had been discussed in a task-specific toolbox talk held just before starting the job.

Lessons learnt/actions taken

- The change of job scope (‘scope creep’) should have triggered a stop, leading to the change being properly managed. A new permit should have been raised with a task specific JRA;

- Members may wish to use this example to highlight the issue of ‘scope creep’ and appropriate Management of Change – particularly where manual handling is involved.

See IMCA SEL 001 – Guidelines for management of change

Members may wish to review the following similar incident in which a person suffered a serious finger injury, in which one causal factor was failure to manage change:

Safety Event

Published: 2 August 2017

Download: IMCA SF 19/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.