Four hand and finger injury incidents

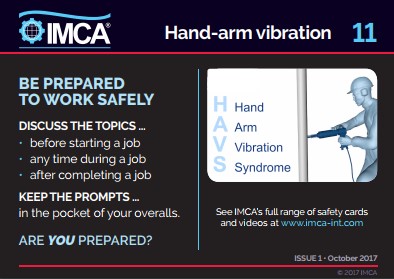

Incident 1 – Company fined after exposing workers to Hand Arm Vibration Syndrome (HAVS)

What happened?

The HSE is reminding companies of the necessity of monitoring workers’ health after an organisation was fined for exposing six maintenance team workers to Hand Arm Vibration Syndrome (HAVS). This was discovered following a health surveillance programme.

What went wrong? What were the causes?

Investigation found:

- The six workers’ conditions were likely to have been caused or worsened by the use of vibratory power tools. Staff in the maintenance and refurbishment departments experienced significant exposure to hand arm vibration in their daily work which put them at risk of developing or exacerbating existing HAVS;

- The company neither adequately planned its working methods nor trained or informed employees on the risks to their health;

- The company did not limit the duration and magnitude of exposure to vibration and failed to put in place suitable health surveillance to identify problems at an early stage.

Hand Arm Vibration Syndrome (HAVS) is a serious and permanent condition caused by regular and frequent exposure to hand-arm vibration. HAVS results in tingling, numbness, pain and loss of strength in the hands which may affect the ability to do work safely and cause pain, distress and sleep disturbance.

Members may wish to refer to the following similar incidents:

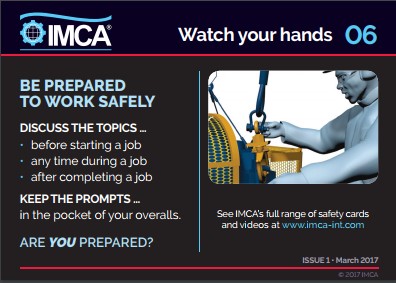

Incident 2 – Welder loses two fingers when manual lift goes wrong

An engineering company was fined after a worker suffered injuries to three fingers when they were crushed by a metal frame he was attempting to lift with colleagues. A worker suffered crushed fingers when a metal frame weighing approximately 250 kilograms fell whilst it was being lifted manually to carry out welding. Two fingers were partially amputated later as a result of his injuries.

What went wrong? What were the causes?

Investigation found:

- Manual lifting and turning of these frames was not an isolated occurrence and a number of the frames had been made in this manner over the three years that the company has been in existence;

- No steps had been taken to avoid the manual handling or to assess the manual handling operation and take steps to reduce the likelihood of injury.

Members may wish to refer to the following incident:

Incident 3 – worker’s fingers severed

What happened?

A worker had four fingers amputated while operating a metalworking lathe. An employee had been using emery cloth to clean steel shafts on a metalworking lathe. He was holding the emery cloth by hand when his gloves became entangled in the lathe. He lost four fingers on his right hand, broke several bones in his left arm and dislocated his wrist as a result.

What went wrong?

Investigation found that the company had failed to ensure the work to clean the metal shafts was carried out safely. It wasn’t an isolated incident and their employees had been applying emery cloth directly by hand on the lathe for several years prior to the accident.

The HSE Inspector said that this employee “suffered life changing injuries in an accident that could have easily been prevented. The risks involved with applying emery cloth by hand on metalworking lathes are widely known and the company should have done more to ensure that they carried out the work in a safe manner.”

This incident is identical – save only the outcome which was worse in this case to the August 2017 incident:

Incident 4 – worker suffers crush injuries

What happened?

A worker suffered crush injuries from trapping his hand in an unguarded printing machine. An employee was injured when his hand was drawn into the print rollers while he was attempting to clean the running machine resulting in partial amputation of two fingers.

What went wrong?

Investigation found that the lack of guarding on the machine was the root cause of this incident together with a lack of training and supervision.

The HSE inspector said “This case serves as a reminder to industry that planning and guarding of machinery requires regular reviews and monitoring to ensure workplace safety. The need to review machinery guarding is a positive benefit to improving workplace safety”.

Members may wish to review the following incident:

Members are encouraged to bring to the attention of their crews, The IMCA safety promotional materials on hand safety and other topics, available free to members here.

Safety Event

Published: 12 December 2017

Download: IMCA SF 30/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.