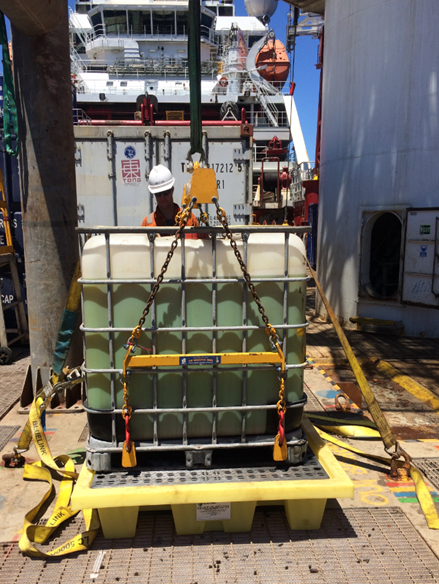

Dropped object – intermediate bulk container (IBC)

What happened?

An intermediate bulk container (IBC) was dropped from a crane to deck. The incident occurred when a vessel crane was being used with a certified lifting device to lift and move an IBC containing 1000kg of monoethylene glycol. As the IBC was moved, the liquid inside was sloshed around (owing to the ‘free surface’ effect) which changed the centre of gravity. This change in the centre of gravity caused the IBC to rotate, resulting in the lift rigging device being unable to support the load. Subsequently the IBC fell approximately 3.5 metres to the deck and burst open, spilling the contents. The spill was contained onboard with no pollution to the environment.

(re-enactment)

What went wrong?

There was no adequate risk assessment of the effects of the possible combination of:

- The ‘free surface’ effect in the liquid within the IBC;

- Vessel movement in sea states (within limits and minor);

- Crane movement.

The rigging installed to lift the IBC – whilst certified – was of incorrect selection which created:

- Minimal resistance to side loading;

- The lift bars were able to slide under the base of the load;

- The load was lifted below the centre of gravity.

What were the causes?

Our members’ investigation is ongoing, but the current cause analysis determined:

- Inadequate risk assessment of the lift;

- Inappropriate selection of rigging arrangement;

- Inappropriate design of storage equipment/containers for liquids which require movement in the offshore environment.

What actions were taken? What lessons were learned?

- Review and re-assess the selection and use of liquid storage containers;

- Review and re-assess the lifting and rigging arrangements in accordance to identified international standards;

- Lift plans and associated risk assessments should include not only lifting and rigging arrangements but also possible movement of loads within storage containers which may affect centre of gravity.

Our member also prohibited the lifting of IBC’s utilising ‘pallet’ type rigging arrangements, and made arrangements to transfer all IBCs into appropriately designed and certified lifting frames.

Members may wish to review the following incidents:

- Uncontrolled rotation of 9.6m reel [investigation revealed a failure to recognise the importance of a change in the centre of gravity of a large and complex structure]

- Fatality during lifting operations [early investigation noted that a heavy load moved in an unexpected way for a number of reasons, including induced momentum from crane swing, induced spin from offset of the centre of gravity, and vessel motion from sea state]

- Dropped pallet during loading of stores

Safety Event

Published: 24 April 2018

Download: IMCA SF 09/18

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.