- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Near miss: unplanned release of 2″ blasting hose outlet from air receiver coupling clamp

What happened?

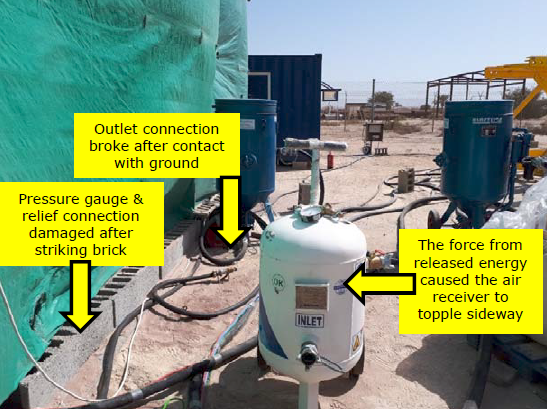

During blasting and painting operations conducted at an onshore worksite, a near miss incident occurred when a 2″ blasting hose outlet released from the coupling clamp connected to an air receiver. The 2″ hose was arrested by the hose restraint. The force from the released energy caused the air receiver to fall sideways striking the ground and adjacent objects, resulting in equipment damage. No personnel were standing in the immediate area or line of fire when the incident occurred.

What went wrong? What were the causes?

- The 2″ hose dislodged from the hose shank due to an improperly tightened Chicago connector;

- The air receiver was placed on sand and was unstable and contributed to the air receiver tank falling sideways.

What actions were taken? What lessons were learned?

- Ensure that risk assessments are carried out. Implement controls to ensure that equipment is appropriately placed on suitable stable footings (hard standing) and that appropriate restraints are in place;

- Assess the application of Chicago connectors with a view to replacing them with alternatives when high pressure applications are identified;

- Regularly review and inspect all pressure related connections to ensure that they are correctly assembled and fitted with adequate whip checks/restraints;

- Assess that barriers are in place to ensure an effective safe distance is achieved to protect personnel from any unplanned pressure release or equipment failure.

Members may wish to refer to:

Two older incidents from 2003:

Safety Event

Published: 23 August 2018

Download: IMCA SF 18/18

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.