High potential near miss: tensioner pad dropped to under deck carousel

What happened?

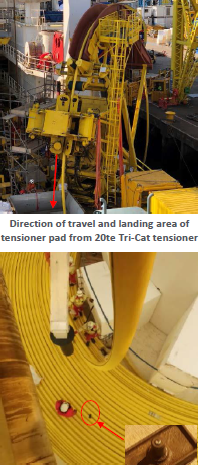

During the trans-spooling of an umbilical, a tensioner pad retaining bolt sheared, resulting in a 1.5kg tensioner pad dislodging and falling 11m to the under-deck carousel, where it struck the already trans-spooled umbilical. The dropped pad then bounced towards the starboard side, narrowly missing the deck supervisor, and landed on a salt sack approximately 1 metre from him.

What went wrong? What were the causes?

- A decision had been taken not to change the grade 8.8 bolts with the 10.9 bolts, due to resources, timescale and difficulty of access;

- The retaining bolt was not subject to an inspection, nor were the torque values checked due to the difficulty in accessing the tensioner;

- Risk assessments had not been conducted prior to the work activity, therefore there had been no consideration of potential dropped objects or mitigation thereof.

What actions were taken? What lessons were learned?

- Replace M10 x 25mm grade 8.8 retaining bolts with M10 x 25mm grade 10.9 on all equipment prior to mobilisation to vessels;

- Corrective work orders to be fully completed inclusive of inspection of tensioner pad retaining bolts and torque value checks, prior to mobilising equipment to vessels;

- Risk assessment of this type of work should take place before it starts.

Members may wish to refer to:

Safety Event

Published: 3 December 2018

Download: IMCA SF 26/18

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.