- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

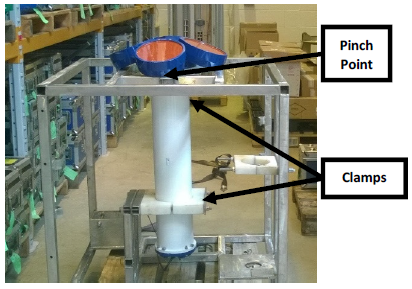

Line of fire/pinch point – fractured fingers

What happened?

A crewman suffered a pinch point injury resulting in two fractured fingers and a fingertip amputation. The incident occurred when a piece of equipment weighing 86kg was being installed by warehouse personnel into a seabed frame. The equipment was lowered into the frame using a forklift with a lifting attachment, but before the securing clamps were fully tightened, the lifting strops were removed.

It was then observed that the equipment was not aligned correctly, so it was manually turned in the frame. Whilst turning the equipment it slipped through the hand tightened clamps, crushing the injured person’s fingers between the equipment and the frame.

What went wrong? What were the causes?

Our member’s investigation found:

- There was no risk assessment or work instruction in place for this task. This was found to be the case for many of the routine tasks carried out in the warehouse/workshop;

- The warehouse team had not carried out this task before without supervision;

- There were insufficient engineering controls to prevent the incident from occurring.

What actions were taken? What lessons were learned?

- A straightforward modification to the seabed frame engineered out the pinch point. When designing equipment, it is vital that safety during installation, maintenance and transportation is considered, as well as operational safety;

- Review workshop, warehouse and yard activities to ensure that suitable risk assessments are in place and used:

- seemingly routine activities should be adequately supervised and subject to suitable and sufficient task risk assessment; in this instance, no risk assessment or instruction was in place covering the task

- previously the task had always been supervised by a senior engineer, but on this occasion, the workshop personnel carried it out unsupervised.

Members may wish to refer to:

Safety Event

Published: 3 May 2019

Download: IMCA SF 09/19

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.