- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Potential for diver injury operating a hand-held torque wrench

What happened?

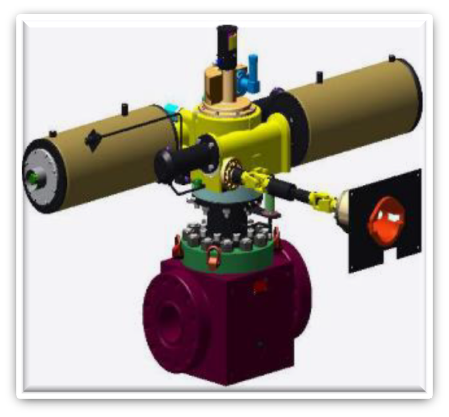

A diver was involved in a near miss that could have resulted in serious injury when he was asked to function an ROV valve override on a subsea isolation valve with a hand-held torque wrench.

A diver was asked to operate an ROV override switch with a hand-held torque wrench. The operation was observed by a third-party technician who intervened and stopped the job. The use of hand-held torque wrench to operate an ROV override on the valve was inappropriate due to the possibility of a sudden uncontrolled unwinding of the spring mechanism; this could have caused the torque wrench to rotate and hit the diver.

What went wrong?

- The warnings on the GA (general assembly) drawing stating that hand-held tools should not be used were ambiguous and were missed;

- The valves procedure issued by the client did not include a warning or highlight the dangers of using hand-held tools to operate the ROV override;

- Engineers were not issued with the appropriate installation operations manual which included warnings not to use hand-held tools;

- The assumption was made that a hand-held torque wrench could be used. Our member notes that similar incidents have occurred within the organisation.

What actions were taken?

- Any operation of an ROV override on a double actuated spring ¼ turn ball valve (fail safe) should not be operated with a manual hand-held torque tool unless there is clear confirmation from the client or the valve manufacturer that it is safe to do so.

Members may wish to refer:

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.