- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

High potential LTI: rigger ear injury

What happened?

A crewman suffered a serious ear injury whilst removing some temporary rigging suspended from a crane gantry walkway. The incident could have been much more serious; the potential was for a critical injury or fatality.

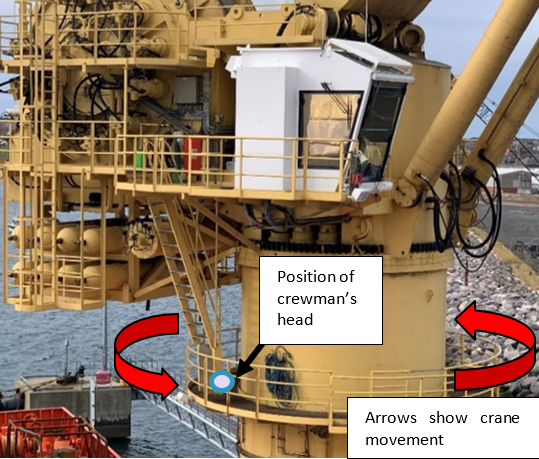

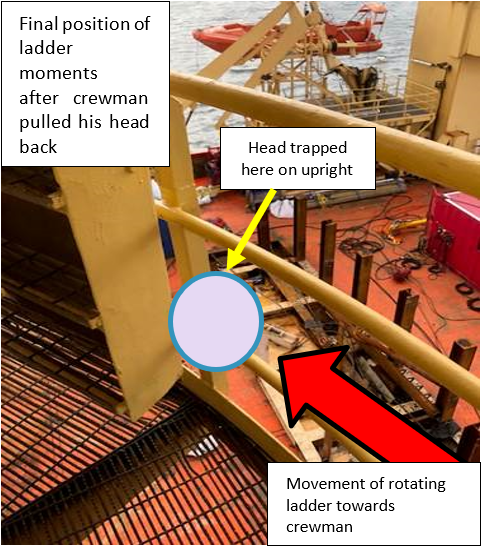

A vessel was alongside demobilising when a crewman went up onto the crane gantry walkway to remove some temporary rigging. In doing so, he kneeled and put his head close to the handrailing. The steel access ladders of the crane cab, which moves with the crane as it slews, pushed his head against the railing upright. As he pulled back hard to free himself from being trapped part of his left ear was severed.

What went wrong?

Findings were:

- Lack of situational awareness/perception of risk;

- Ineffective communication and coordination protocol between the deck team and crane operator for access control to crane gantry;

- Ineffective assessment of hazards associated with on-site modification when introducing the temporary rigging;

- Bypassing warning signs and barriers by the crewman.

What actions were taken?

- Standardise signage and barriers around crane structures or other areas with large moving machinery;

- Ensure lifting procedures outline minimum requirements for communication and coordination protocol for lifting operations;

- Consistent use of dynamic risk assessment to identify risks arising from potential hazards in the ongoing and changing circumstances of work activities – this means asking what’s changed and how this affects actions taken and instructions given;

- Review of control measures in place around crane access/areas with large moving machinery e.g. guarding, walkways, cameras, alarms, barriers;

- Consider whether suitable vessel-specific task risk assessments are in place for access to cranes and other areas of moving machinery and that these are well communicated to personnel e.g. during vessel, deck, ROV and dive system familiarisations and walkarounds;

- Ensure that changes, such as installation of small items of temporary rigging, are fully considered and risk assessed as part of a documented management of change (MoC);

- Use IOGP Life Saving Rules as a prompt whilst using risk management tools (TRA/TBT/MOC) – consider what Life Saving Rules are relevant to the task in hand.

Members may wish to refer to:

Safety Event

Published: 6 March 2020

Download: IMCA SF 09/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.