Serious injury caused by high-pressure washer

What happened?

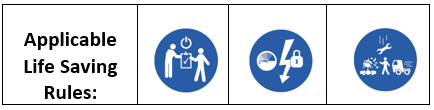

A work team supervisor sustained a laceration to his upper right thigh caused by a high-pressure water jet. The injury required several stitches and the injured party was retained in hospital overnight. The incident occurred when personnel from a third-party shipyard company were using a high-pressure water jet (250 bar) to clean the vessel thruster grating located on the dock floor. The operator of the high-pressure lance did not anticipate the hydraulic kick-back force when engaging the trigger of the lance. The surge in water pressure caused him to step back and turn to his left to regain his footing. In doing this, his lance turned with his body and inadvertently sprayed his supervisor who was standing behind him.

What were the causes? What went wrong?

The operator did not install barriers around his working area and the supervisor failed to enforce the use of barriers on the dock bottom. The use of barriers was required by the task risk assessment (TRA). The supervisor had placed himself in the line of fire by approaching the operator from behind without the operator knowing he was there.

What actions were taken?

- Take appropriate Time out for Safety (TOFS);

- Ensure all your site task risk assessments (TRAs) involving high-pressure equipment state the need for appropriate barriers to be in place, and at a safe distance from the work activity, to prevent access to all non-essential personnel;

- Ensure that those supervising tasks involving high-pressure equipment understand that they are non-essential personnel during the task;

- Ensure that any vessel in dry dock has a formal plan to restrict access to the dock bottom and barriers are in place where there are identified hazards on the dock floor;

- Ensure that all personnel involved in the operation of high-pressure equipment have the appropriate competency and use personal protective equipment rated to the pressure of the equipment in use.

Members may wish to refer to:

- Guidance on safety in shipyards (IMCA HSSE 032)

- LTI: diver injured during water jetting operations (July 2018)

- LTI: Leg injury caused during HP water jetting (May 2017)

- Lost time injury (LTI): Serious hand injury during high pressure washing operations (May 2016)

- Diver sustains water jetting injury (March 2015

- Code of practice for the use of high pressure jetting equipment by divers (IMCA D 049)

Safety Event

Published: 12 June 2020

Download: IMCA SF 18/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.