Forklift truck incident

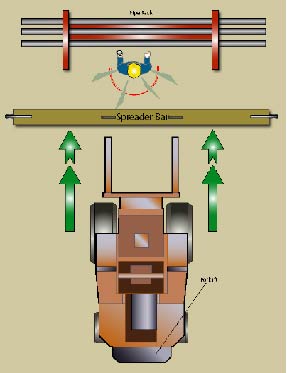

A member has reported an incident in which an employee was injured whilst working with a forklift truck. Two crew members had placed slings on a pipe and planned to move it with a forklift truck and a spreader bar consisting of an i-beam 2½ metres long by 20cm wide. The pipe was located in a pipe rack.

The forklift was parked on the opposite side of the spreader bar with the forks on the deck with the motor turned off. One of the crew got in the forklift, started it and lifted the forks to position them to have the slings placed on the forks. The other crew member was holding the slings and standing between the rack and the spreader bar.

The forks hit the spreader bar and moved it toward the rack, catching the individual’s left calf between the bar and the rack and causing severe bruising. He subsequently had to visit the doctor and the injury lead to a time lost from work of around two weeks.

The injured crew member was a short service employee who was being mentored by a more experienced ‘lead man’. The more experienced mentor had left the scene before the forklift truck was started to perform another task elsewhere, leaving the lift to another crew member and the short service employee.

The company has noted the following lessons learned:

- The inexperienced crew member did not appreciate that he was putting himself in a hazardous situation; nor did his co-worker take action to prevent this unsafe act;

- The mentoring program had not worked as intended. The mentoring program and a proper explanation of work procedures should be emphasised in pre-shift meetings and during vessel orientation;

- If the mentor had to leave the immediate work area during lifting operations, work should stop until that they returned;

- Personnel should inspect their work areas and identify hazards that need to be removed;

- Mentors should to emphasise work procedures in a toolbox talk whenever there are changes to the circumstances of the work being conducted;

- Mentors should identify the risks associated with a task to short service employees and explain the hazards and preventative measures;

- All workers should remember the saying ‘never place yourself between a rock and a hard place’ and beware of potential crush zones!

Safety Event

Published: 10 May 2007

Download: IMCA SF 04/07

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.