- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Bell bottom door hydraulic operating system failure

A member has reported the failure of a bell bottom door hydraulic operating system. The failure occurred while carrying out standard bell recovery operations using the port dive bell on a twin bell system.

While attempting to close the dive bell bottom door, it was noted that the bottom door did not fully close and that the bottom door had castellated. Further attempts were made to close the door fully which exacerbated the situation, resulting in the bottom hatch being jammed more solidly.

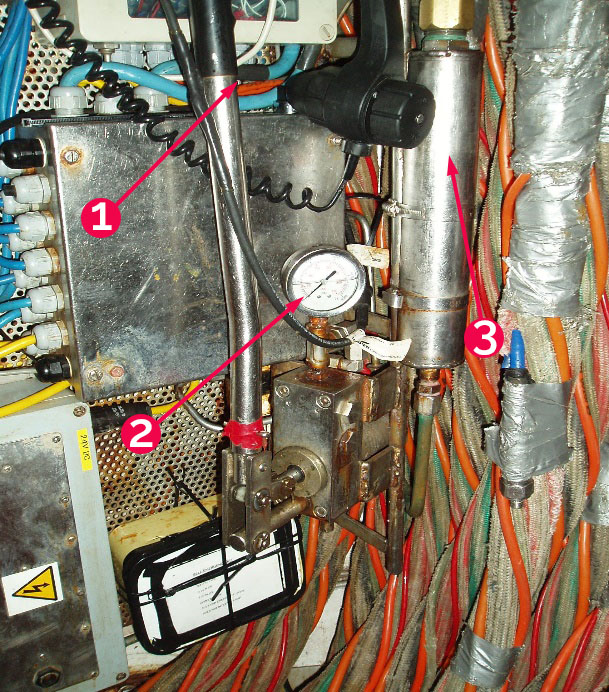

The divers carried out an internal dive bell inspection and found that the hydraulic control system had failed due to hydraulic system oil loss.

Several unsuccessful attempts to rotate the bottom door were made including topping up the hydraulic oil system tank and also removing sections of the internal hydraulic operating pipework in an attempt to rotate the bottom hatch manually.

The bottom door was found to have jammed to such an extent that the divers were unable to produce sufficient torque, using the manual tools available in the dive bell, to turn it.

The decision was made to launch the starboard dive bell and effect diver recovery using the member’s ‘through water transfer’ procedure to the starboard bell which went without incident with all divers successfully returned to the system.

The cause of the failure was found to be a ferrule which had become detached from a hydraulic pipe in the control system, rendering the bottom door hydraulic system inoperable.

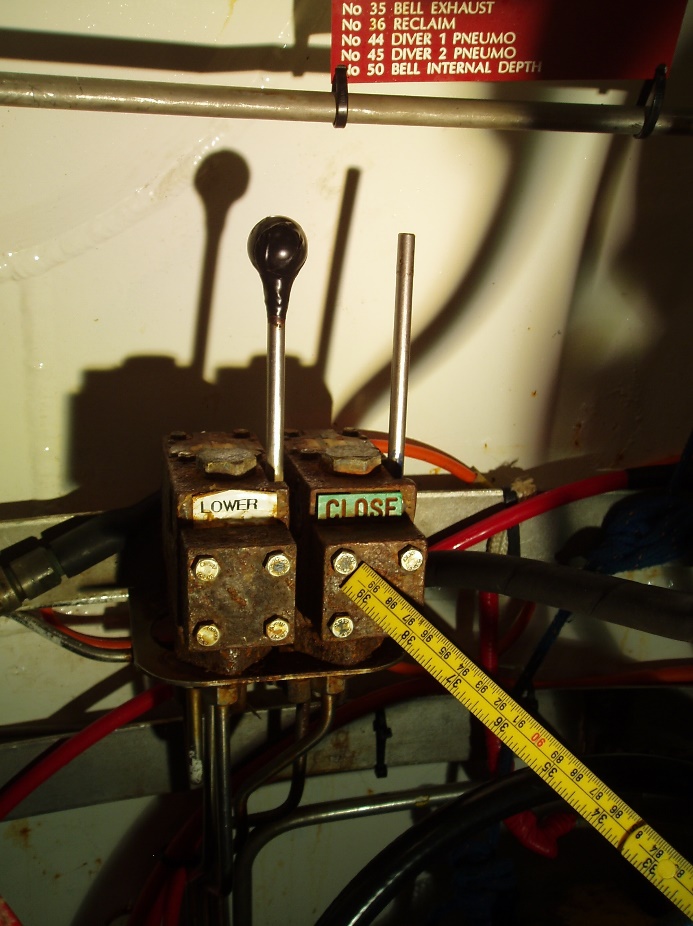

The member noted that the individual operations of opening/closing and rotation of the bottom door were controlled by directional control valves (DCVs) and that both valves could be operated simultaneously, so that in essence both opening/closing and rotation could be carried out at the same time.

The following corrective actions were taken:

- visual system designed inside the dive bell to show that castellations are in line, to allow for better control by the diver;

- interlock between directional control valves fitted;

- procedure for operating bottom hatch posted locally in bell and in dive control;

- familiarisation, training and exercises improved for dive bell bottom door operation;

- technical description and emergency procedures prepared and posted in dive bell and dive control;

- failure modes and effects analysis (FMEA) reviewed with regard to bottom hatch operation;

- maintenance plan reviewed.

Safety Event

Published: 10 November 2009

Download: IMCA SF 16/09

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.