- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Incidents of failure of jet drives on wind farm service vessels

A member has reported a number of incidents involving jet drives on wind farm service vessels.

Incident 1: Loss of Jet Drive Control on Wind Farm Service Vessel

A wind farm service vessel lost control of its jet drives. The incident occurred when a wind farm service vessel was underway returning to port from the wind farm. Control of the port jet was lost and the vessel veered heavily to port. The port jet was shut down and the vessel returned to base on one engine escorted by another wind farm service vessel.

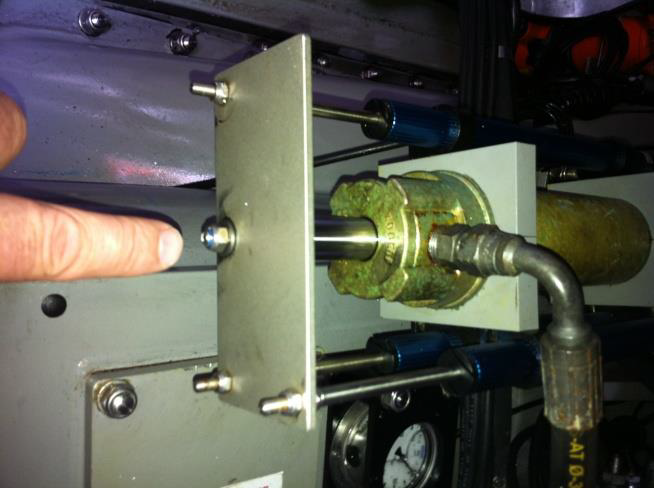

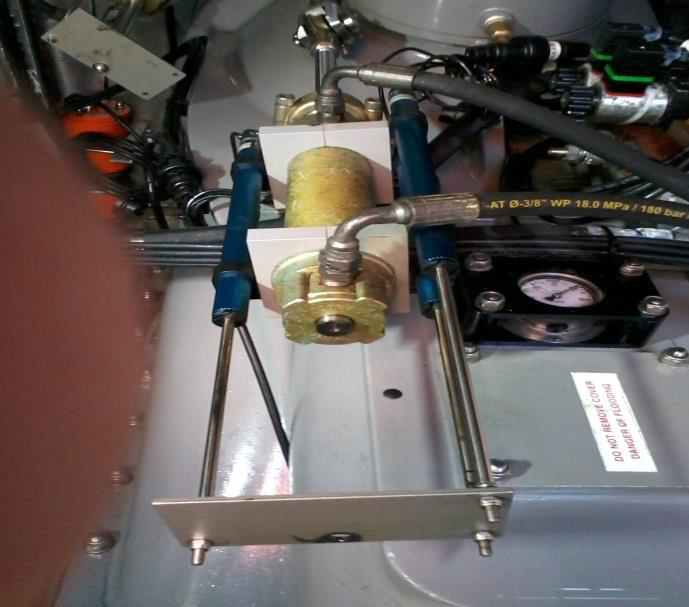

Our member’s investigation revealed the following: . An M6 size bolt, securing the steering feedback transducer plate to the end of the steering ram, had vibrated loose and fallen off into the bilge; . This resulted in a loss of steering control of the unit.

Our member took the following action and learnt the following lessons:

- The steering feedback transducer plate was reconnected and LocTite or similar used on the nut and bolt;

- The repair operation could have been conducted offshore without returning to port;

- When the rams are disconnected from the transducer plate for maintenance purposes, the nut and bolt should be secured with an agent like LocTite or similar to prevent the bolt from vibrating loose; . Wind farm vessel crews should have a thorough technical understanding of the vessels they are using.

-

Incident 2: Failure of Jet Drive on Start-up

Before starting the jets, before starting the day’s operations, it was found that the starboard jet failed to respond. Initial fault finding consisted of shutting down and restarting the starboard jet and changing over the relays. This did not work. An attempt was then made to manoeuvre using the local solenoid control – this did work. Following local control, the jet operated normally on all control systems and operations were resumed. As a result, the vessel was 45 minutes late for operations.

Our member’s investigation revealed the following:

- The gearbox had been maintained earlier in the week;

- The jet had performed for 45 minutes since the gearbox was serviced;

- Use of the local solenoid control restored the system to operation;

- The cause of the incident was suspected air within the system.

Our member recommended that:

- Knowledge of the local control is included as part of the emergency procedures in the company competence programme;

- Wind farm service vessel skippers should be aware of the possibility of using local control systems;

- The use of local control systems should be part of ‘routine’ fault finding.

Safety Event

Published: 19 July 2013

Download: IMCA SF 12/13

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.