- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Near-miss: Unexpected water ingress during fault finding of a cracked water pipe

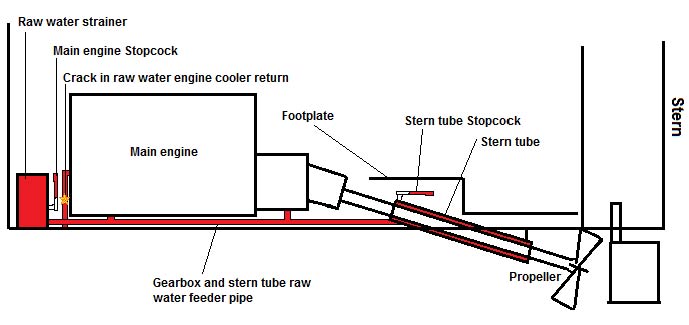

A member has reported a near miss incident in which large volumes of sea water were found in the bilges of a small boat (offshore wind turbine CTV). The water was discovered during pre-shut down checks when the vessel was alongside. After initial fault finding it was found that there was a leak due to a cracked raw water cooling return pipe from the port side main engine. The crew closed the raw water sea chest and after making every effort to temporarily seal the crack, went ashore to seek a long-term solution.

When the crew returned to the engine room it was found that the leak had continued to flow into the bilge, though not much had entered the bilge; it was thought that it was probably resting water from the engine. The bung was removed and the water flow was monitored to check that the resting water was emptying out of the system, after approximately 20 minutes the water had not ceased to stop flowing and the crew became concerned.

Our member notes:

- During subsequent further fault finding to eliminate the source of the water flow it was found that the flow was coming from the stern tube;

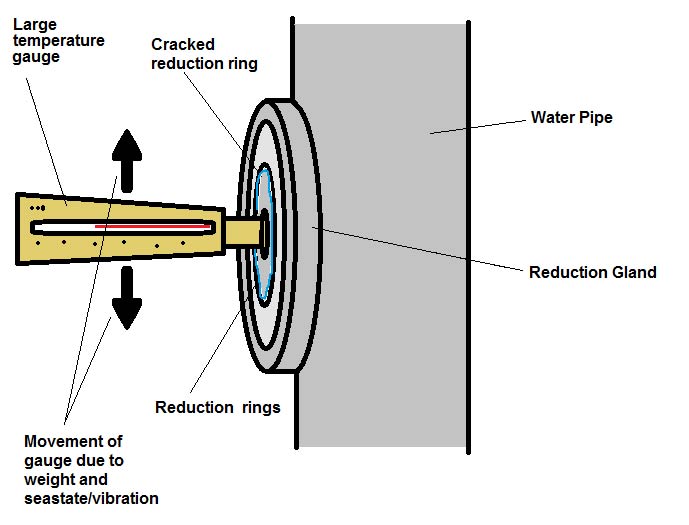

- This particular type of vessel was propeller driven with water lubricated stern tubes. Underneath the floor plate at the stern gland there was another seacock; . This seacock had not been highlighted to the crew during delivery of the vessel; . There was no hatch in the foot plate to allow easy access to the valve; . The pipe was repaired the following morning; . An investigation is currently underway as to why the pipe cracked. Preliminary consideration was that it may be due to the weight of the temperature gauge causing the pipe to weaken over time. Our member required the crews of other similar CTVs from the same manufacturer to check the plastic pipes in the engine rooms regularly for signs of deterioration or stress around the reduction glands and temperature/pressure gauges, and any deficiencies were to be immediately reported to the management.

Members may wish to refer to the following incidents (key words: water, ingress, CTV, engine):

- Loss of a vessel (owing to water ingress to engine room)

- Water ingress to bow thruster space

- Fire in wheelhouse on offshore renewables crew transfer vessel

Safety Event

Published: 29 May 2015

Download: IMCA SF 07/15

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.