Use of third-party equipment leads to DP undesired event

- DP Event

- Published on 30 November 2018

- Generated on 22 February 2026

- DPE 04/18

- 2 minute read

Undesired event

Jump to:

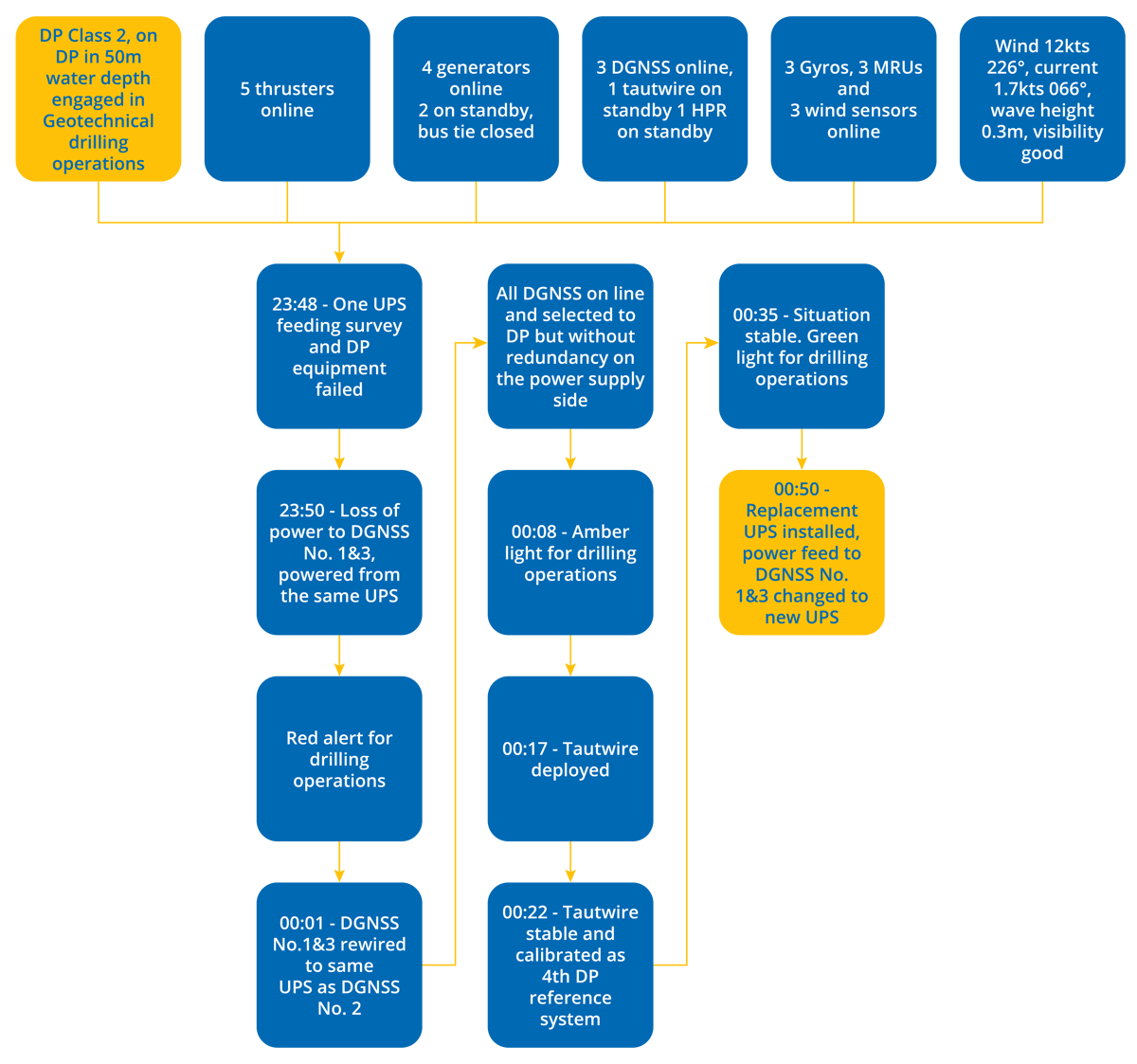

DP equipment should not be repaired and brought online after repair without being suitably tested.

Comments

The UPS and the DGNSS source does not fall under the vessel’s planned maintenance system (PMS), as this is owned by the survey company. The equipment is maintained and tested before it is installed on a vessel.

While the testing of signal dropout and UPS function is part of the vessel’s DP checklists, there is no electrical maintenance or routine testing on the specific UPS while in service onboard; the backup strategy is to keep a spare UPS onboard.

Redundancies worked as designed; no critical situation developed. Drilling operations suspended purely due to loss of redundancy.

An additional checklist to routinely test the capabilities of the UPS was developed and implemented as part of the vessel PMS.

Considerations

- The online position reference systems (PRS), 3 x DGNSS, do not provide adequate redundancy according to industry guidance.

- Considering the time taken to select the taut wire it appears ‘stand-by’ meant that the depressor weight was still on deck and not deployed.

- Reference should be made Guidance on operational activity planning (IMCA M220).

- The report indicates that two of the PRSs were supplied with power from a UPS that was not designated for the DP system.

- The DP FMEA should be revisited to verify the effects of failures of the DP UPSs and the power distribution supplying the UPSs. It should be verified that the arrangements, the UPS endurance and the PRS set up for the industrial mission are in accordance with the DP Class 2 requirements.

- DP equipment should not be repaired and brought online after repair without being suitably tested.

- A proper assessment should be made, and MoC procedure followed when connecting third party equipment to the DP system.

- Reference should be made to Guidelines on the shared use of sensors for survey and positioning purposes (IMCA M235).

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.