High potential near-miss: Failure of both divers’ breathing air supply and dive stage recovery winch

- Safety Flash

- Published on 7 January 2016

- Generated on 14 July 2025

- IMCA SF 01/16

- 4 minute read

Jump to:

A member has reported a near miss incident in which a diver lost his breathing air supply and at the same time there was a failure of a dive stage recovery winch.

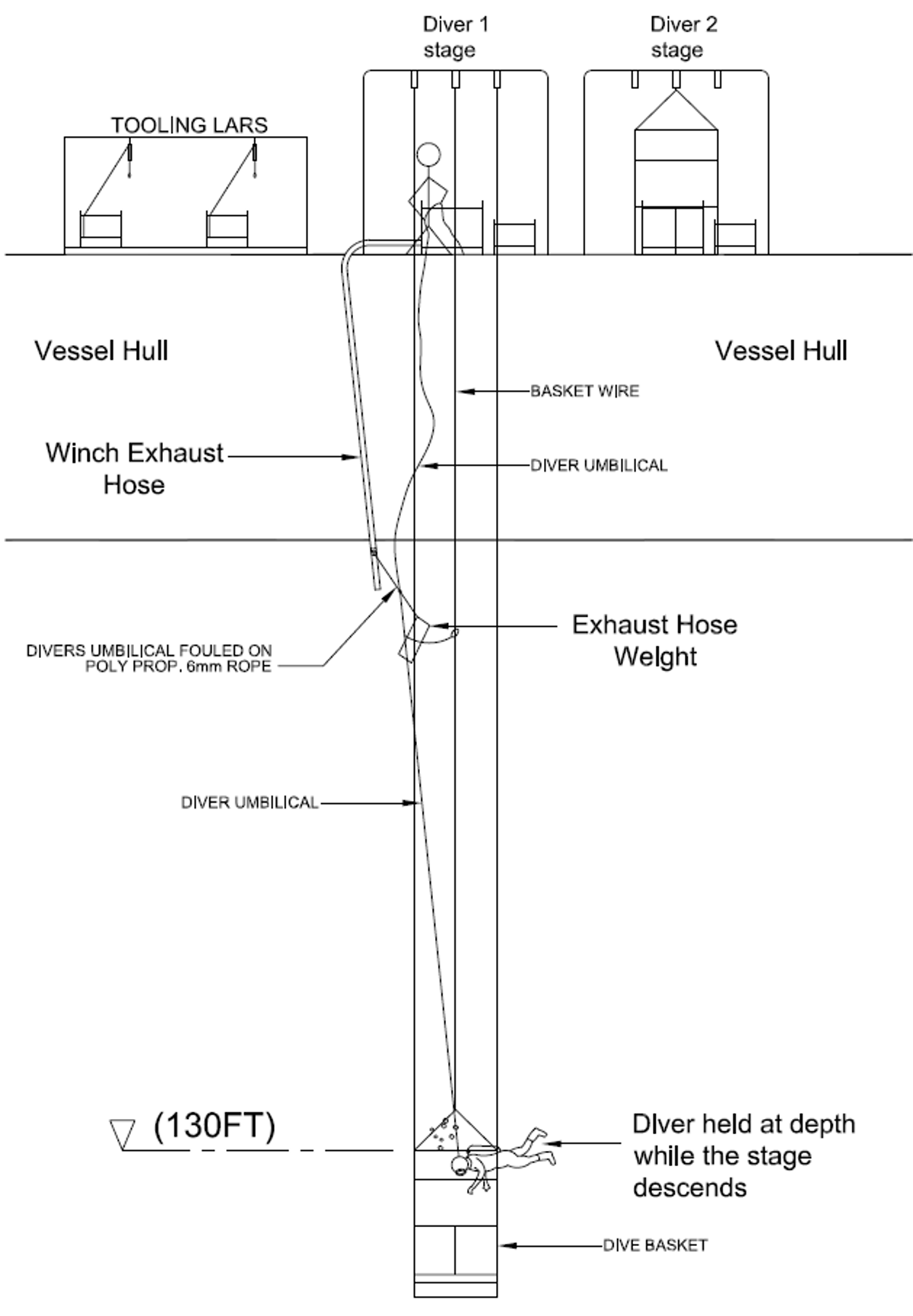

The incident occurred on a Dynamic Positioning (DP) Diving Support Vessel (DSV) when a surface orientated air dive was planned for a depth of 160fsw. The dive stage was to be located at 130fsw. For reducing the noise exposure on deck, the LARS (Launch and Recovery System) air winch exhaust hose had been positioned in the water at the side of the vessel, close to where the diver 1 basket entered the water. A weight was attached by way of a lanyard at the hose end to prevent flailing while the winch was being operated (see diagram).

Whilst the diver was in the stage travelling to 130fsw, the running line connecting the umbilical to the stage wire became entangled with the winch exhaust hose weight. This entanglement was responsible for:

- Kinking of umbilical gas and pneumo hoses with subsequent loss of air supply to the diver.

- Kinking of the winch exhaust hose and subsequent failure of the winch.

- Prevention of free pay-out of the umbilical giving rise to the diver being held in position in the water column whilst the stage continued to descend.

The diver went immediately onto his emergency gas supply (bail-out cylinder). The diver was pulled to the roof of the stage onto his side which limited his access to the basket emergency air cylinder and he was unable to turn the supply on. The winch operator engaged the clump weight winch and was able to bring the basket up which caused the restriction to loosen allowing the main supply of gas to return to the diver. The dive was discontinued and the diver was returned to the surface safely. He was unharmed and there was no damage to equipment.

The incident had high potential as there could have been severe injury to the diver.

Our member investigation noted the following:

- The most probable immediate cause was a combination suspended exhaust hose and weight to ‘wander’ more than usual. This in turn led to the entanglement of the weight with the carabiner.

- Should a situation occur in which the winch’s air motor exhaust (of discharged pressurised air) is restricted or prevented from flowing freely through the control valves exhaust port, this condition will cause the air motor to slow to a stall, ceasing all rotation and operation. This is commonly referred to as ‘choking’ the exhaust and is to be avoided in all cases as it will dramatically affect the performance of the air motor. The motor enters a ‘stall condition’ as the inlet and discharge pressure balance against each other and the motor ceases rotating.

The following went right:

- The diver went immediately onto his emergency gas supply (bail-out cylinder).

- The team reacted in a calm and professional manner – no panic.

- Safe resolution of a complicated and dangerous situation was made in a matter of minutes.

- The black box recording was available and captured key elements of the incident for review and historical purposes.

The following immediate corrective actions were taken:

- Safety Stand Down’ with the entire diving team to discuss the incident.

- Winch hoses were removed from the proximity of the diving stage to eliminate the threat of entanglement.

- The weight keeping the exhaust hose submerged was secured directly to the hose end rather than by a length of rope, which had been instrumental in the fouling of the lines.

- Update of risk assessment for the positioning of equipment on deck - to include and reflect the situation that occurred.

- Diving umbilical was removed from service and pressure tested by the offshore technicians and checked for any defects;

- Review of deck risk assessment to incorporate the findings of the incident.

In the longer term our Member aimed to:

- Eliminate the use of in water hoses

- Install silencers directly on the winches.

Related Safety Flashes

-

IMCA SF 15/09

23 October 2009

-

IMCA SF 03/09

5 March 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.