Near miss: Diver's umbilical drawn beneath a load

- Safety Flash

- Published on 28 January 2022

- Generated on 10 July 2025

- IMCA SF 03/22

- 2 minute read

Jump to:

Suction from a large glass-reinforced plastic cover during lifting resulted in a diver’s umbilical being drawn beneath the load.

What happened?

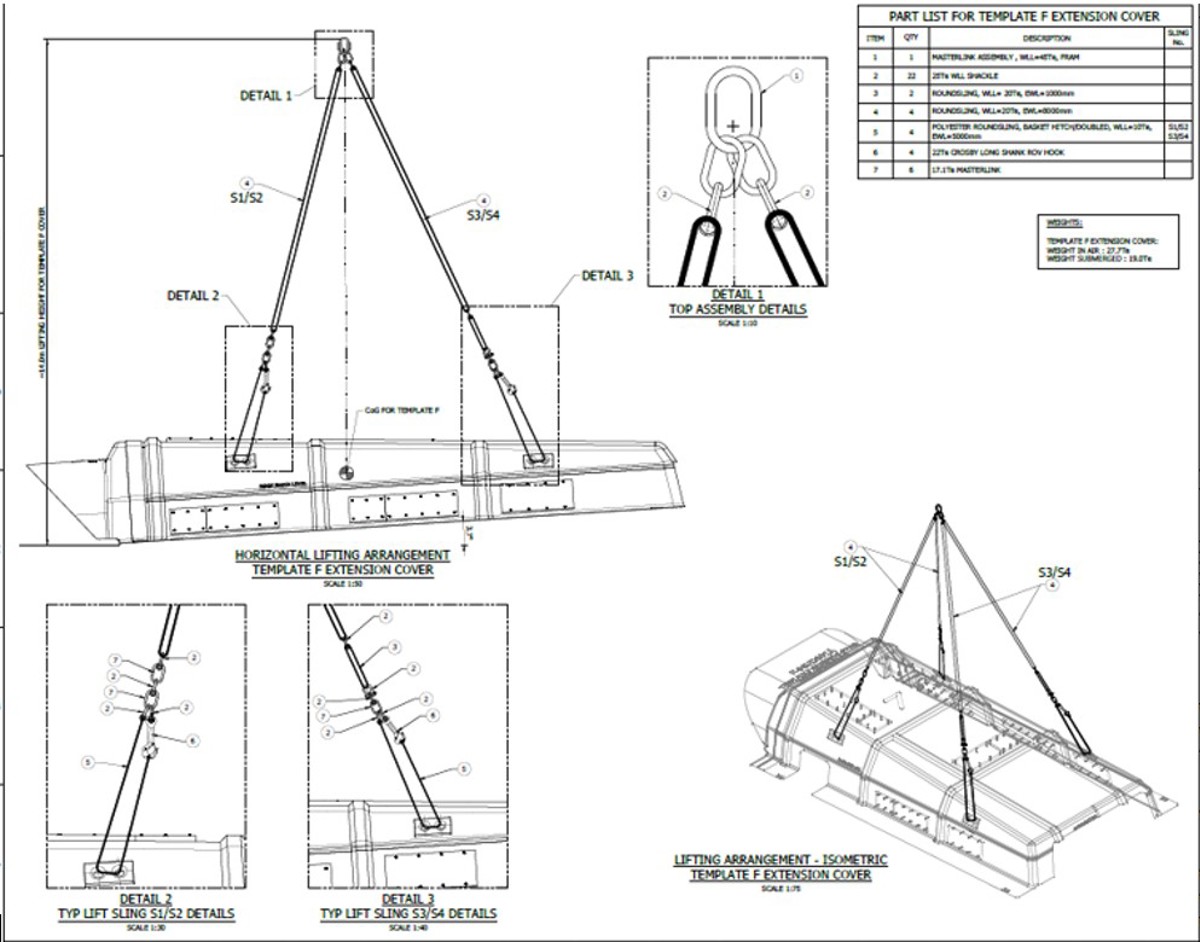

Suction from a large GRP (glass-reinforced plastic) cover during lifting resulted in a diver’s umbilical being drawn beneath the load. The incident occurred during hook-up of the GRP lift rigging, when unexpected movement of the cover led to suction which drew Diver 1’s umbilical under the corner of the cover. The cover was lifted and the divers’ umbilical was cleared. The soft nature of the seabed prevented damage to the umbilical. There was no interruption to any diver’s services, and no injuries.

The GRP cover was in its “wet store” position – there were no associated subsea assets. The weather was within the operating envelope of the crane in terms of vessel motions (heave, pitch & roll). No alarms were present and the vessel was operating within her activity specific operating guidelines.

What went wrong?

During hook up of the cover, using crane active heave compensation, the vessel experienced heave which resulted in the cover being lifted in an unexpected way. This occurred when standing up the rigging in active heave compensation (AHC) to ensure there were no twists prior to switching modes into auto tension (AT). At that moment the vessel took a disproportionally large heave and consequently partially lifted the GRP cover.

What was the cause?

Our member notes that large GRP covers (this one weighed over 20 tons) are notorious for the suction forces they create when being lifted, yet the diver needs to be close to enable the fine placement over assets.

Lessons learned

Although the diver and dive supervisor were not expecting the GRP cover to lift, and good umbilical management had been identified as a requirement in the risk assessment, the potential for this movement of the umbilical to be sucked under the structure had not been identified and the appropriate umbilical management fully recognized.

Related Safety Flashes

-

IMCA SF 20/19

23 August 2019

-

-

IMCA SF 03/17

13 February 2017

-

-

IMCA SF 30/19

17 December 2019

-

-

IMCA SF 20/16

2 August 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.