Lost time injury (LTI): Fall from height leading to multiple fractures

- Safety Flash

- Published on 15 February 2013

- Generated on 4 July 2025

- IMCA SF 04/13

- 2 minute read

Jump to:

A member has reported an incident in which a worker fell 16 m and sustained multiple fractures.

What happened?

The incident occurred when the worker was part of a team dismantling a hanging scaffold on part of a topsides under construction in the yard. The sequence of work meant that scaffolders dismantling the structure ended up supported on the bottom of the droppers (scaffold tubes attached to deck structure to support hanging scaffold).

The worker was climbing the dropper to tie off his safety harness to the deck structure when the dropper slipped through the couplers and fell 16 m with him attached. He sustained multiple fractures and was taken to hospital.

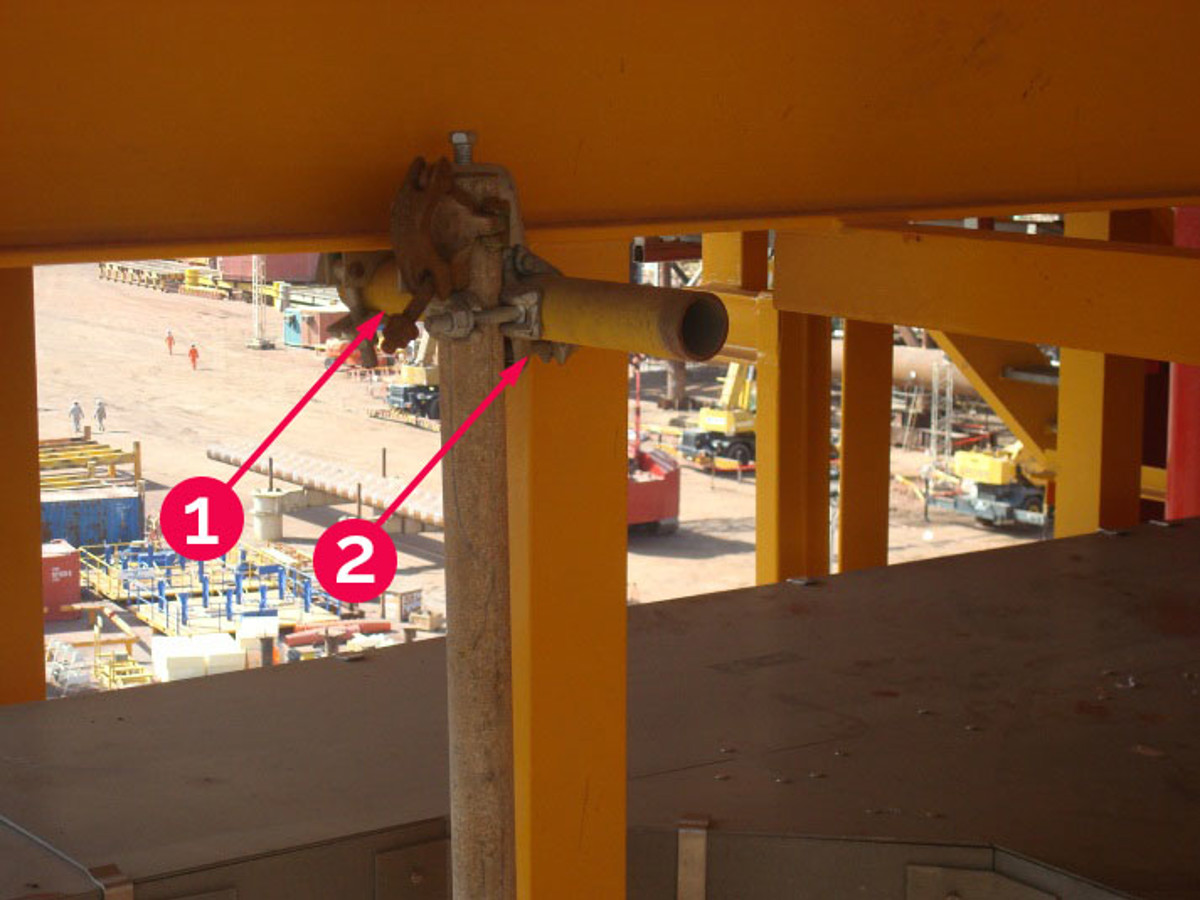

site of incident – circle indicates where dropper was attached, 16 m above ground

Details of scaffolding – 1) safety or check coupler; 2) support coupler

With regard to scaffolding, the following points were made:

- The dropper support coupler is attached to a horizontal tube.

- A second coupler is attached above the support coupler to act as a safety or check coupler.

- The purpose of the safety coupler is to support the dropper should the support coupler become loose.

- In this incident both coupler connections on the dropper became loose allowing the dropper to slide through both couplers and fall.

Findings

An investigation revealed the following causal factors:

- Primary support and safety couplers became loose and failed to support the dropper and the injured person.

- Fall arrest lanyard was connected to the dropper as no consideration had been given to fall arrest being independently tied off from the scaffold, e.g. inertia reel attached to the deck structure.

- No checks were made of the tightness of safety critical couplers after deck stacking and subsequently over a prolonged period (12-14 weeks).

- Partially dismantled scaffold indicated lax control of earlier activities.

- Supervisory personnel in attendance did not correct unsafe working at height practices and require an independent tie off.

- The task was not planned or risk assessed adequately.

Actions

The following recommendations and corrective actions were made:

- When dismantling hanging scaffold always connect the fall arrest to a structure independent of the scaffold being dismantled.

- Where no independent structure is in reach of personal fall arrest lanyards, or a greater degree of movement is required, use an inertia reel.

- Always check tightness of dropper support and safety couplers:

- after stacking or moving of decks and structures when scaffold is pre-installed

- after any alterations are made

- after high wind

- after it has been erected more than 30 days

- before dismantling of scaffold.

- after stacking or moving of decks and structures when scaffold is pre-installed

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.