Lost time injury (LTI) during lifting operations – backloading tubular cargo

- Safety Flash

- Published on 20 March 2015

- Generated on 4 July 2025

- IMCA SF 04/15

- 3 minute read

Jump to:

A Member has reported an incident in which a crew member was injured during lifting operations.

What happened?

The crew member's legs were trapped whilst he was walking between casings being lifted, when one of them moved. The incident occurred during backload of tubular cargo (drill casings) from a nearby rig. The crewman was walking between two casings to connect the pre-rigged lifting slings to the rig crane hook. As he was preparing to connect the lifting strop, the movement of the vessel caused one of the casings to shift, which trapped his legs, causing multiple fractures and serious abrasions to both lower legs. He was medevaced by helicopter and spent approximately two weeks in hospital for treatment and rehabilitation before being repatriated.

Worksite and place where injury occurred

Our member’s investigation noted the following:

- The injured person had been told by the banksman not to walk between the casings but disobeyed the instruction.

- No-one on deck exercised the ‘Stop Work Policy’ (SWP) to immediately halt the operation and correct his unsafe behaviour.

Our member took the following steps: Reviewed risk assessment for cargo handling;

- Ensured that no crew members walked between, underneath or on top of cargoes.

- Ensured that all cargoes were adequately secured to prevent unplanned movement during operations.

- Vessels carrying tubular cargo to check that sufficient quantity of wedges available on board for cargo operations, and raise requisitions in case further wedges were needed.

- When working with tubular cargo, Samson posts to be used whenever possible, to prevent tubular cargo from rolling.

In working with tubular cargo, the following points may be considered:

- Cargo should be loaded in such a way as to minimise movements when offloading. Unnecessary movements of tubular cargo may cause displacement from their safe position and move wedges from their chocking position.

- Wedges used in adequate quantity and size (the size should be at least 25% of the tubular diameter).

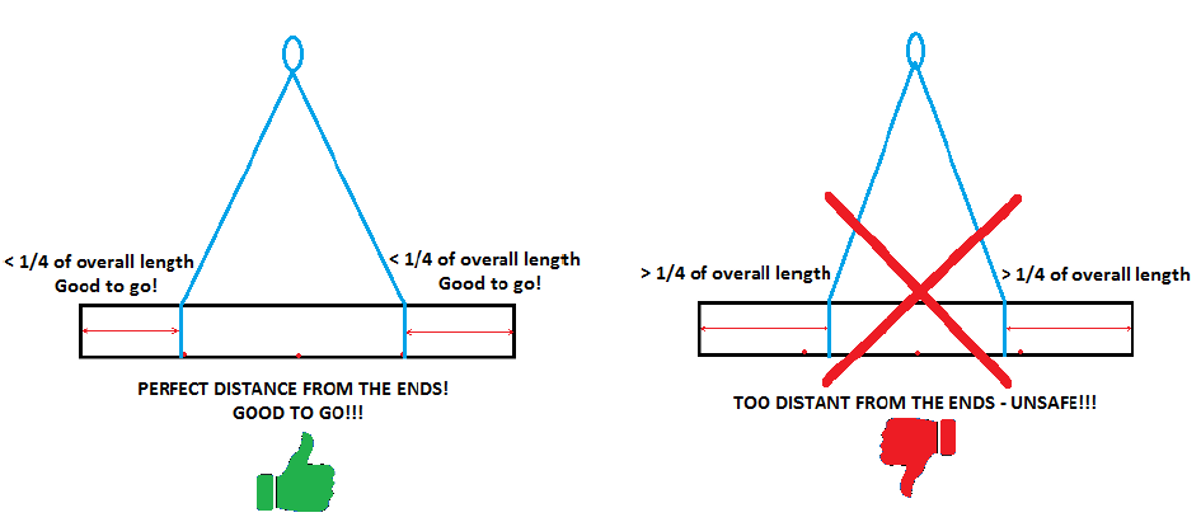

- Slinging should be placed from each end so that distances are never more than 1/4 of the total length of the tubular cargo.

The use of Samson posts should be considered where possible

- Lifting strops should be prepared and laid outside the tubulars so that deck crew can easily access them and make the connection in a safe way.

Crush injuries and other injuries caused by the sudden and unplanned movement of tubular cargo are a recurring theme in IMCA safety flashes.

Related Safety Flashes

-

IMCA SF 02/14

20 February 2014

-

IMCA SF 18/13

20 December 2013

-

IMCA SF 08/06

22 June 2006

-

IMCA SF 10/02

1 October 2002

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.