LTI: Carbon Monoxide (CO) poisoning during Oxy-Acetylene brazing

- Safety Flash

- Published on 16 February 2023

- Generated on 12 July 2025

- IMCA SF 05/23

- 3 minute read

Jump to:

A crew member suffered from Carbon Monoxide (CO) poisoning during oxy-acetylene brazing.

What happened?

The incident occurred when the crew member was involved in repairing a broken valve, part of the Freon pipe system for refrigeration.

While brazing the gas return isolation valve, the crew member felt unwell, but continued the job.

The task was completed after one hour and then the crew member felt breathing difficulties, was coughing and experienced chest pains.

After a coffee break, the crew member sought medical assistance on board. Medical assessment showed he had a low oxygen saturation level.

A medevac was activated due to possible respiratory distress or even heart problems.

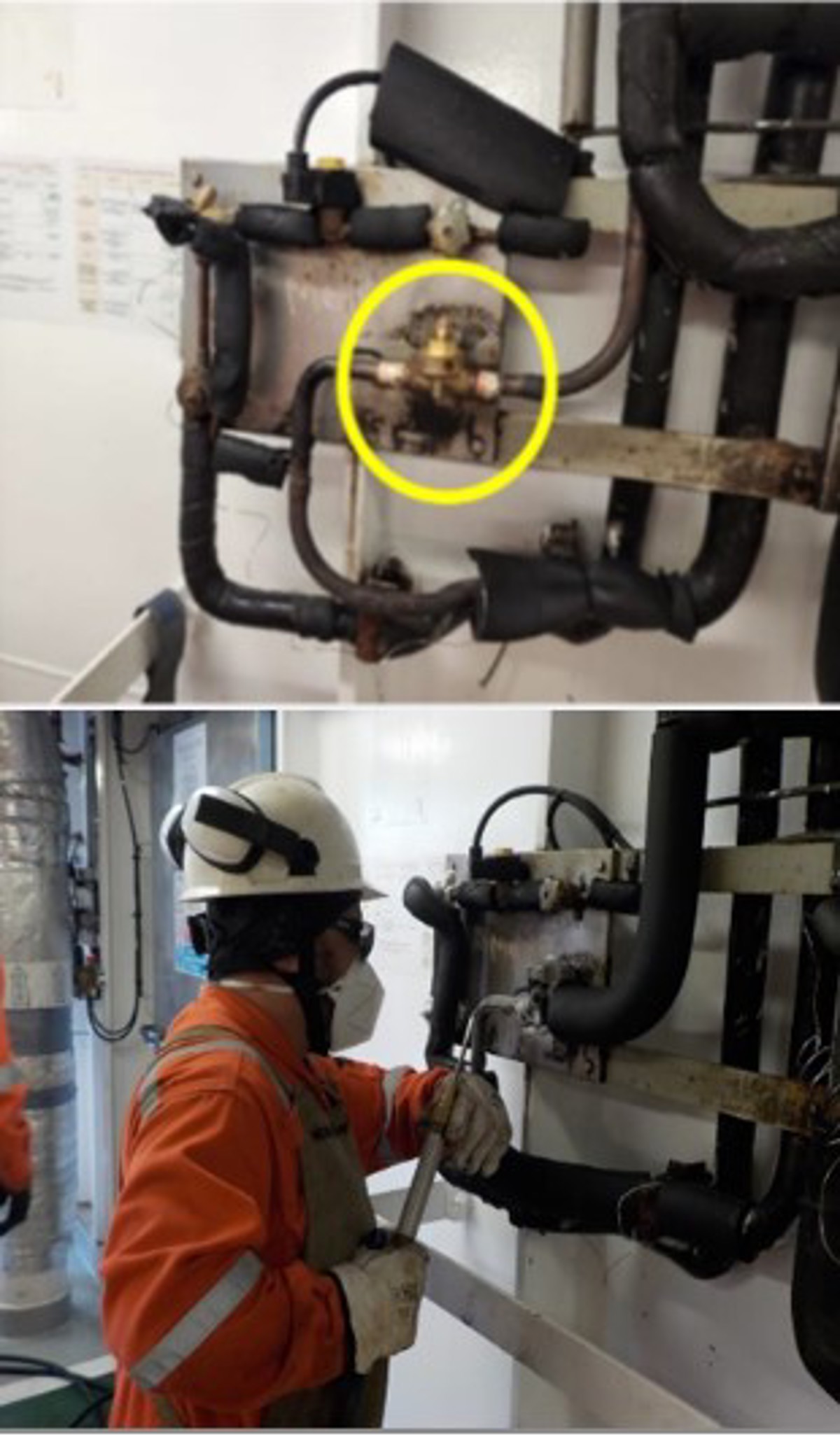

Repair of valve in refrigeration pipework

Crew member conducting oxy-acetylene brazing

What went right?

- The method statement for the repair was to use oxy-acetylene brazing and Tungsten Inert Gas (TIG ) welding methods.

- All safety controls such as Hot Work PTW, Risk Assessment, Toolbox Talk were in place for the job.

What went wrong?

- The crew member did not wear a face mask during the welding job. The company’s procedures did not require the wearing of a face mask for this gas welding, although the wearing of a face mask was identified as a control measure in the risk assessment.

- The risk assessment for the job was incomplete:

- Wearing of a face mask was indicated in the PTW as an “additional protection only”.

- The need for a portable exhaust ventilation system was not identified for this working area.

- The risks and hazards associated with TIG welding were not identified.

- Wearing of a face mask was indicated in the PTW as an “additional protection only”.

- The crew member did not take regular breaks during the task as indicated in the Risk Assessment, and kept on working when he felt ill rather than stopping and reconsidering.

- The crew member was unaware of the risks and hazards associated with TIG welding. The molten metal gives off molecules of metal and ozone which are harmful to respiration.

Lessons learned

- Review condition and availability of portable exhaust ventilation equipment onboard and order more if required.

- Wear a welding mask when carrying out welding jobs.

- Review Risk Assessment for the task with regard to:

- Use of portable exhaust ventilation systems to ensure adequate ventilation.

- Duration of exposure time and rest periods.

- Regular testing of air in areas where CO may be present.

- Risks and hazards associated with Tungsten Inert Gas (TIG) welding.

- Use of portable exhaust ventilation systems to ensure adequate ventilation.

- Use respirators with appropriate canisters, in conjunction with personal CO monitoring, for short periods under certain circumstances where CO levels are not exceedingly high (OSHA PEL for CO is 50 ppm of air averaged during an 8-hour time period).

- Further appropriate refresher training for welders on risk and hazards of all types of welding used onboard.

- Further education for all crew about the sources and conditions that may result in CO poisoning as well as the symptoms and control of CO exposure.

Related safety flashes

-

IMCA SF 10/21

8 April 2021

-

-

IMCA SF 15/18

20 July 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.