Crane wire rope grip incorrectly fitted

- Safety Flash

- Published on 13 May 2014

- Generated on 6 July 2025

- IMCA SF 07/14

- 2 minute read

Jump to:

A near miss incident has come to IMCA’s attention in which a crane wire rope termination was found to be incorrectly fitted.

What happened?

Before starting work at a land-based site, a 30 tonne mobile crane was inspected, and a rope clamp (bulldog) attached to the hoist ropes ‘dead end’ was found to be incorrectly fitted causing crushing and damage to the ‘live end’ of the wire rope (the part of the wire rope that takes the load strain).

The incorrect selection or fitting of wire rope grips drastically reduces the efficiency of the wire rope terminations and can cause the wire rope to slip through the grips, potentially leading to the harm of people and damage to the equipment.

The bridge of the clamp must always be fitted on the working part (live end) of the rope, and the U bolt on the rope tail (dead end) of the rope.

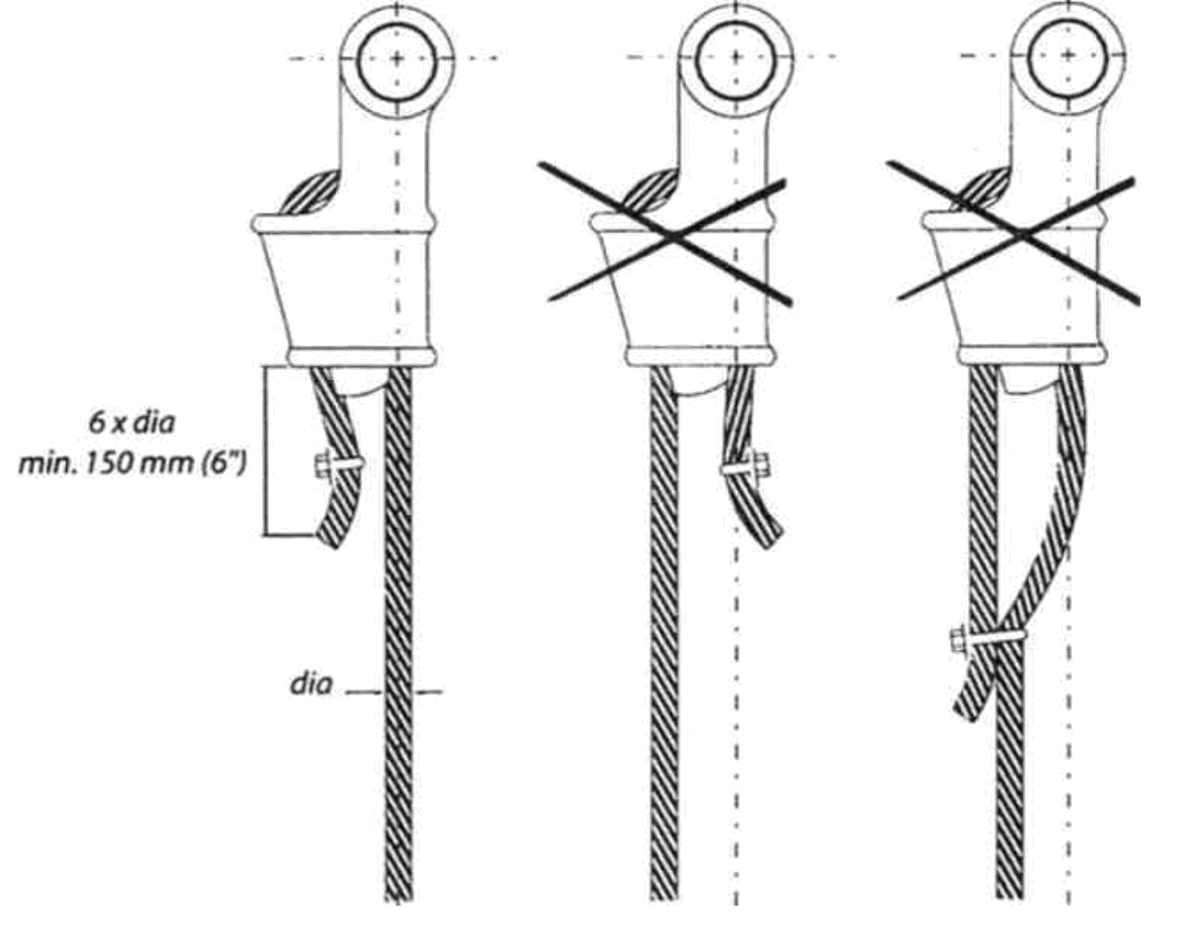

Wedge socket showing right and wrong method of termination

For a wedge Socket, the wire rope grip should NOT be connected to the live rope. It should only be connected to the dead end of the rope. Any clamping at all, bridge or U bolt, to the live end of a rope terminated with a wedge socket can cause damage and crushing and is not recommended.

Incorrect fitting of wire rope grips

The following lessons were learnt:

- Ensure correct type of wire rope grip is selected when terminating wire ropes.

- Ensure wire rope grips are correctly fitted.

- Watch out for signs that may indicate broken wires; e.g. reduction in rope diameter, corrosion or rope deformation.

Members may also wish to refer to IMCA LR006 Guidelines for lifting operations.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.