A Member has reported an incident in which a pontoon cleat was damaged during offshore renewables Crew Transfer Vessel mooring operations.

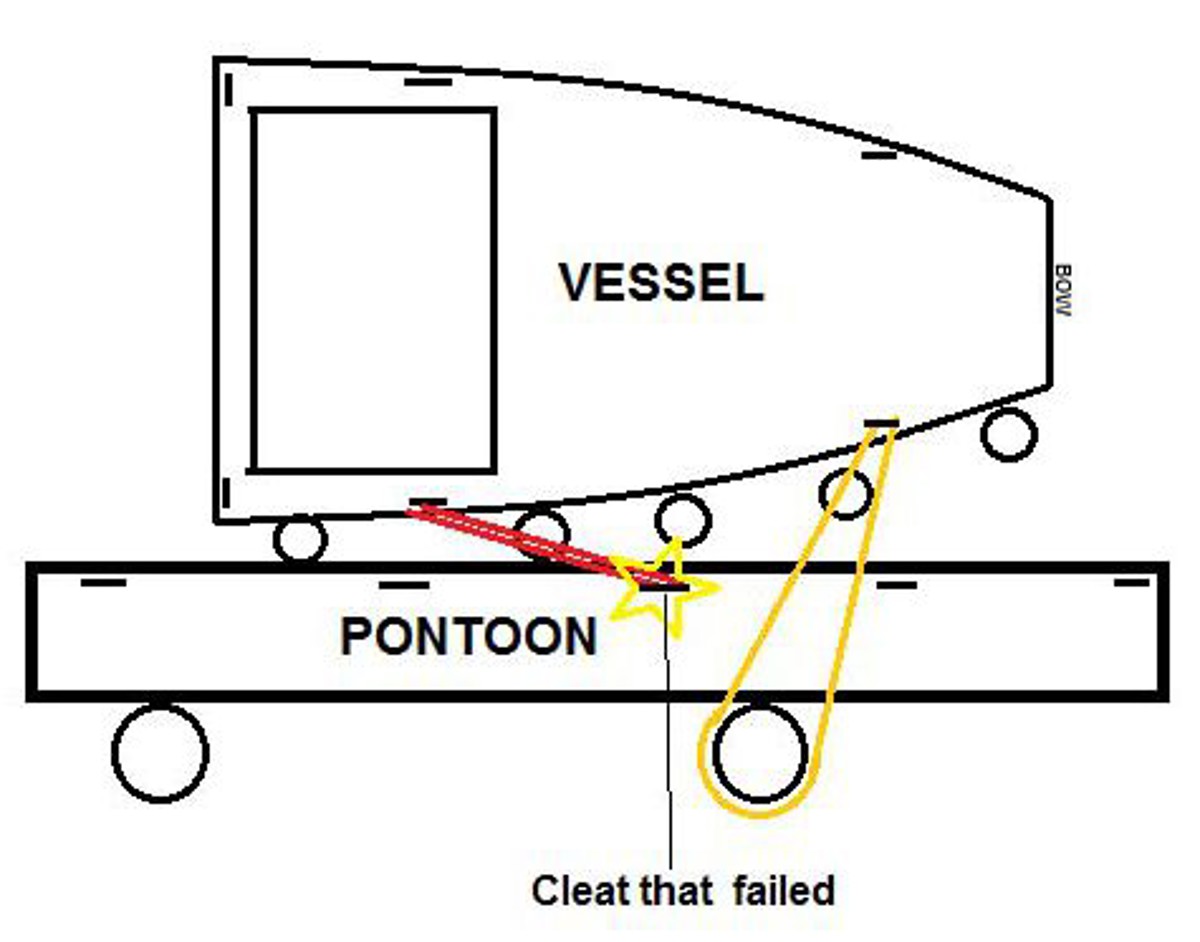

The incident occurred when the vessel was leaving its berth. When the mooring lines were being removed, the master caused the vessel to pull back onto the spring line to allow the forward breast line to be released.

At this point the mooring cleat on the pontoon gave way and broke, flying across the pontoon near to where a crewman was standing whilst assisting with the mooring ropes. There was minor damage and no injuries.

damaged cleat

schematic showing mooring line layout at the time of damage

Findings

Our Member’s investigation noted the following:

- The vessel was alongside due to very strong winds and was waiting for the next opportunity to sail.

- Owing to the strong winds, the vessel had been secured with additional mooring lines around the pontoon uprights to help alleviate pressure.

- The vessel had been moored in position for six days alongside the pontoon and had been tied to the same cleats for the whole time, most probably weakening the cleat due to the increased stress of the large vessel weight added to the wind force pulling on them.

- The vessel had been pushed away from the pontoon by the wind, which put significant stress onto the mooring cleats, possibly leading to equipment/material fatigue and consequent increased likelihood of failure.

- This particular model of CTV was Fixed Pitch Propeller driven and also has a large air draft, making it susceptible to being affected by the wind whilst moored or manoeuvring.

- When the vessel was preparing to leave the pontoon to begin work after the bad weather, one mooring line had been left attached for one reason or another and come under load as a result of the vessel’s movements.

Actions

Our Member recommended:

- Larger, heavier crew transfer vessels should moor onto pontoon uprights or purpose-made heavy duty mooring points during bad weather, this was to avoid unnecessary stress or weakening to pontoon equipment designed typically for use by yachts and smaller vessels.

- Improve communications between master and crew onboard the CTV (for example, holding a toolbox talk) before manoeuvres were made in order to get underway, this was to avoid mooring lines being left attached and coming under load. In these cases the casualty was a cleat, but it could easily have been a critical piece of equipment or even an arm or leg.

- ‘Closed loop’ communications should be adopted, i.e. feedback made that all communications were properly understood before action taken.

Members may wish to refer to the following:

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.