Near-miss: Bell umbilical damage incident

- Safety Flash

- Published on 24 July 2012

- Generated on 10 July 2025

- IMCA SF 08/12

- 3 minute read

Jump to:

A Member has reported an incident in which a diving bell umbilical was damaged after it was trapped between the cursor and the bell.

What happened?

After completion of diving operations a deck foreman was in the vessel bell garage assisting with bell recovery operations. He noticed that the white tape mark on the bell umbilical and the white tape mark on the cursor wire were not aligned as the curser started to rise. He called an ‘all stop’ and the situation was investigated.

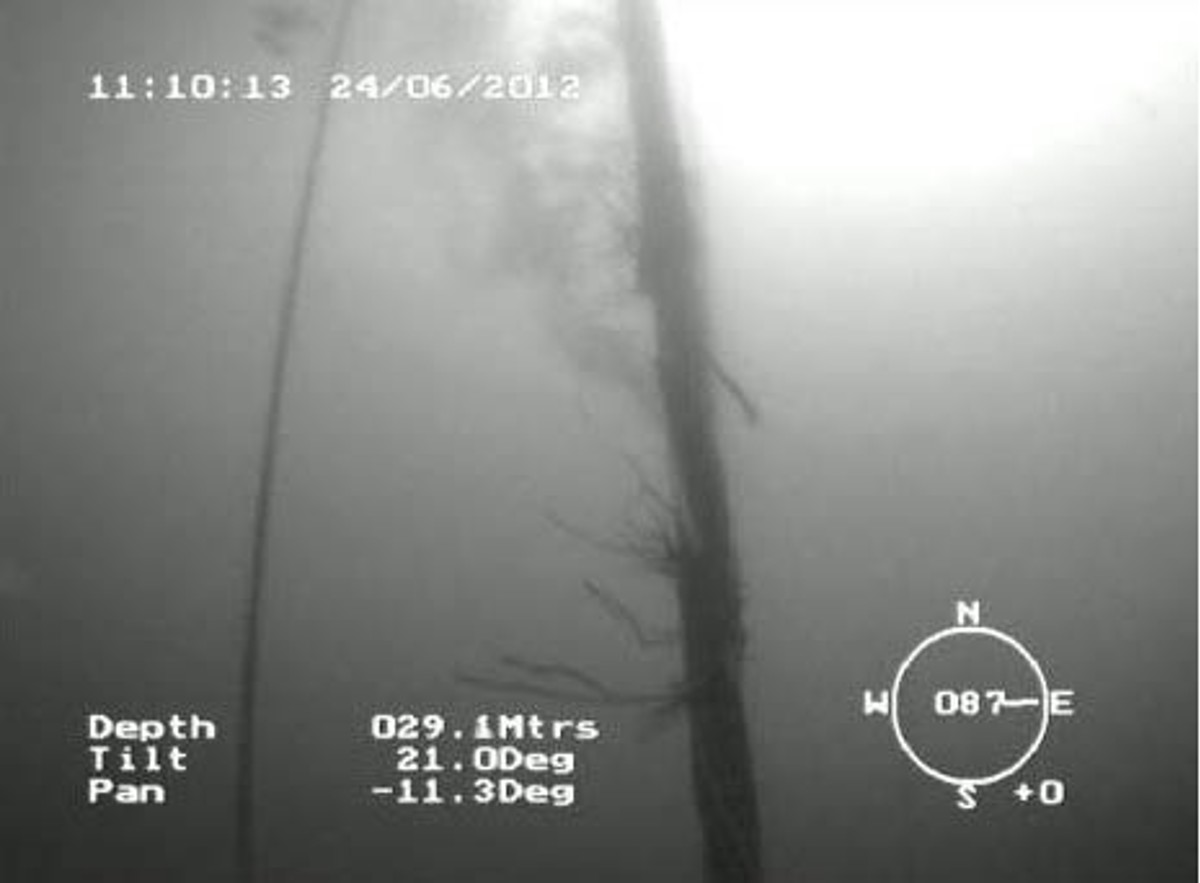

It was found that the umbilical was snagged under the upper guide wire slot on the cursor and was trapped between the cursor and the bell. The deck foreman advised the dive supervisor who lowered the bell back to 30m of sea water, in order to investigate the problem further. The umbilical was freed by slackening it and slowly raising the bell on the main winch. A Remote Operated Vehicle (ROV) was used to check the condition of the bell umbilical.

A slight leak was detected from damage observed to the umbilical outer sheath and a small amount of gas could be seen coming from one of the small pneumo-fathometer hoses. The divers secured the pneumo valves and the leak was stopped. The bell left 30m and internal pressure was maintained. The bell arrived on surface and was locked onto the system. All of the bell internal valves were closed and the system was bled down and the bell prepared for surfacing and sealed. All valves were secured inside the bell and the bell was recovered with the correct amount of tension on the umbilical for immediate transfer of the divers and assessment of the damage in the dry. There was no loss of integrity to the bell and the divers inside were unharmed.

View from ROV showing damaged umbilical leaking gas

During an investigation the following points were noted:

- The immediate cause of the incident was found to be that the dive supervisor did not ensure sufficient tension on the bell umbilical to eliminate the risk of it bunching, trapping and being damaged during bell recovery operations.

- Underlying causes identified were as follows:

- loss of control: the dive supervisor lost concentration when distracted during the aft bell recovery operations/activities. Existing procedural and engineering control measures which might have prevented this were not effectively applied.

- design: the differential read-out monitor alarm indicator is a visual alarm only, and not audible also, which could go unnoticed.

- It was unclear whether or not the dive supervisor had noticed the visual alarm (red flashing bell in the screen of the differential read-out monitor) which highlights the differential selected for each dive undertaken.

- The dive supervisor was a very experienced member of the dive team, with great experience in using on-board bell launch and recovery systems, and had performed bell deployment and recovery operations numerous times in the past. On this occasion the dive supervisor believes he had become distracted and had not paid attention to the length of umbilical paid out prior to recovery.

- Experience and competence in tasks does not mean that the risks of being distracted, or losing focus, does not remain high when undertaking what may be considered ‘routine’ tasks.

The following corrective and preventative actions were taken:

- Re-termination of umbilical.

- Installation of an audible alarm onto the differential panel read-out on the hydraulic control panel, which will enhance pre-existing warning controls of differentials when recovering dive bells.

- Bell launch/recovery risk assessments reviewed and updated with incident findings and addition hazard control measures.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.