Dropped spanner falls 15 m

- Safety Flash

- Published on 20 April 2023

- Generated on 12 July 2025

- IMCA SF 10/23

- 3 minute read

Jump to:

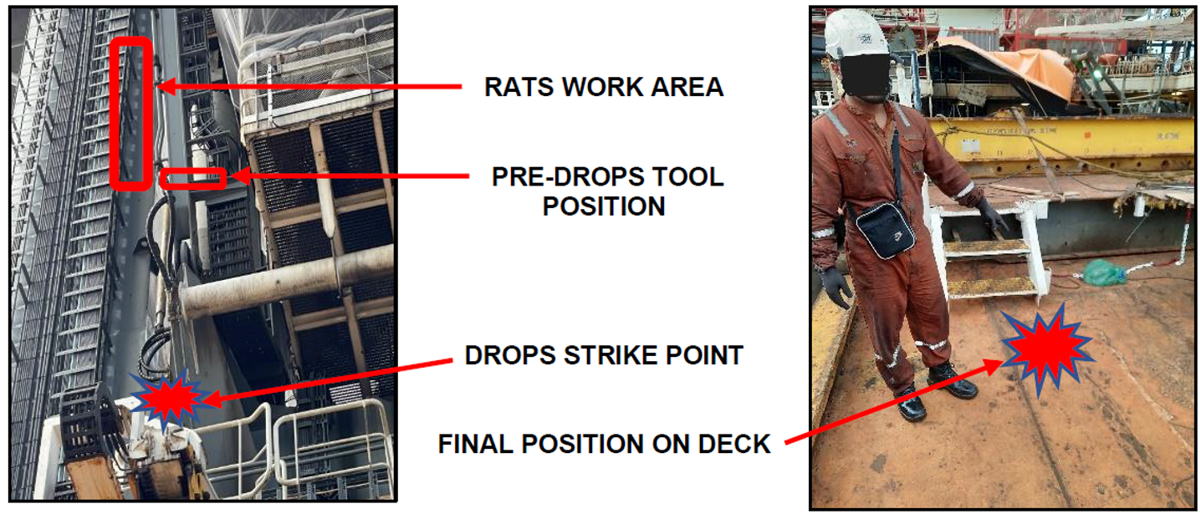

During work at height, a spanner became disconnected from its DROPS protection lanyard whilst crew were working in an area outside the installed protective netting. The spanner then fell to deck 15 metres below.

What happened?

Protective netting had been installed for general maintenance on a pipelay system, which would be carried out by crew members and a third-party Rope Access Team.

During work on hydraulic hose replacement, a member of the third-party Rope Access Team observed two hoses outside the netting protected area and proceeded to replace them.

A spanner (60 mm x 1.65 kg) was used, secured to the team member by a 1.2m DROPS prevention tooling lanyard, connected by threaded carabiners at both ends.

During the replacement the carabiner threads became loose allowing the carabiner to open.

The spanner fell 15 metres to the deck area below which was partially barriered off.

No-one was injured. However, workers were nearby on deck.

What went wrong?

Investigation findings:

- The third-party Rope Access Team identified additional hydraulic hoses to replace which were outside the area protected by the netting. This additional work was not authorised, and they claimed to be unaware of the received instructions to only work within the perimeter protected by the netting.

- The third-party Rope Access Team recognised that they may have neglected to secure the carabiner correctly. They reported that the spanner fell from the tower structure and when load was placed on the lanyard recoiled upwards causing the carabiner to disconnect and fall.

- It was noted that because there is no swivel in the wire lanyard, there was a risk of the carabiner opening if the carabiner thread was open. The carabiner threads were also found to be heavily worn and contaminated which compromised the locking mechanism. The pre-work inspection failed to identify the equipment conditions. The DROPS tool kits were not covered within the planned maintenance system.

- People were also observed crossing the barriers below the activity. This was not stopped nor reported to the supervisor. In addition, there had been insufficient assessment of the overall DROPS cone to account for the DROPS path or deflection.

Actions

Our member took the following actions:

- Ensured all work teams were aware of the scope and limit of work activities and knew to not go beyond those limits without review from management.

- Ensured completion of pre-task inspection of tools/accessories for Working at Height.

- Subjected all Working at Height tools to regular inspection, maintenance and replaced defective parts as required.

- Considered barriers appropriate to the specific nature of the task – taking into account the DROPS cone.

- Properly manage barriers to ensure they are suitably positioned for the work, with sign-off to confirm purpose.

Members may wish to review:

- HSS039 Technip DROPS

- HSS042 Saipem DROPS – choice not chance

- HSS043 Subsea 7 DROPS

Related safety flashes

-

IMCA SF 24/22

1 November 2022

-

-

IMCA SF 20/18

10 September 2018

-

-

IMCA SF 02/15

5 February 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.