Inspection notice from Crosby on certain products

- Safety Flash

- Published on 3 May 2023

- Generated on 5 July 2025

- IMCA SF 11/23

- 3 minute read

The Crosby Group has asked that IMCA circulate the following information as part of a Safety Flash.

Crosby has been made aware (March 2023) of a few instances of hoist rings that have an important assembly component missing. In those instances, the retaining pins used to secure the hinge pins were not in place and allowed a hinge pin to come out during unloaded condition.

Internal testing has confirmed that these hoist rings can sustain the working load limit with only one hinge pin in place. However, Crosby recommends the listed hoist rings be immediately inspected to confirm the retaining pins are in place.

The inspection is simple and can be completed quickly with the hoist rings installed and unloaded.

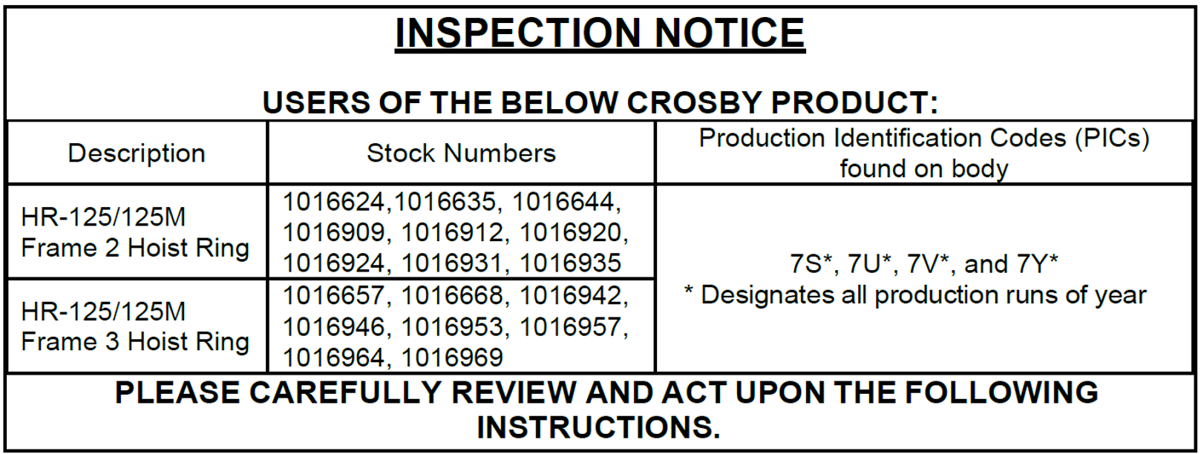

Crosby requests you perform the inspection on the above listed products with the listed production identification codes (PICs) found on the body. Crosby has prepared the below instructions to perform the necessary inspection. The inspection uses a small flat tool to gently pry the hinge pins outward, to confirm they are positively secured. If any hoist rings are found with inadequately secured hinge pins, please remove from service, and notify Crosby Technical Support at 1-800-220-8509 or crosbytechsupport@thecrosbygroup.com for immediate replacement.

Please inform your customer(s) of this Inspection Notice, or if you know of other users of the HR-125/125M Hoist Rings, please pass this notice on to that user, company, or firm. To ensure further circulation of this inspection notice to potential users of the products, it is being provided to safety minded industry organisations for posting on their safety notification sites.

We regret the inconvenience this may cause you and your organisation and thank you for your cooperation. We are committed to providing you with the absolute best in Crosby quality.

Sincerely,

THE CROSBY GROUP

If any hoist rings are found with inadequately secured hinge pins, please remove from service, and notify Crosby Technical Support at 1-800-220-8509 or crosbytechsupport@thecrosbygroup.com for immediate replacement.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.