First aid injury: Person struck by wire under tension

- Safety Flash

- Published on 6 May 2016

- Generated on 15 July 2025

- IMCA SF 12/16

- 3 minute read

Jump to:

A member has reported an incident in which a crew person was struck by a wire under tension.

What happened?

The incident occurred when a rigging crew were preparing to transfer a piece of subsea infrastructure – an inline tee (ILT) – from a supply vessel to the installation vessel. The tagging tower wire was transferred and connected to the ILT on the deck of the supply vessel. At this point the rigging supervisor requested the winch operator to ‘pay-in’ in order to take up the slack. The wire, which had been slack at this point, became taut and struck a person involved in the operation. An ‘all stop’ was called, and the area made safe. The injured person was sent to see the medic for a check-up. First aid was administered for minor abrasions.

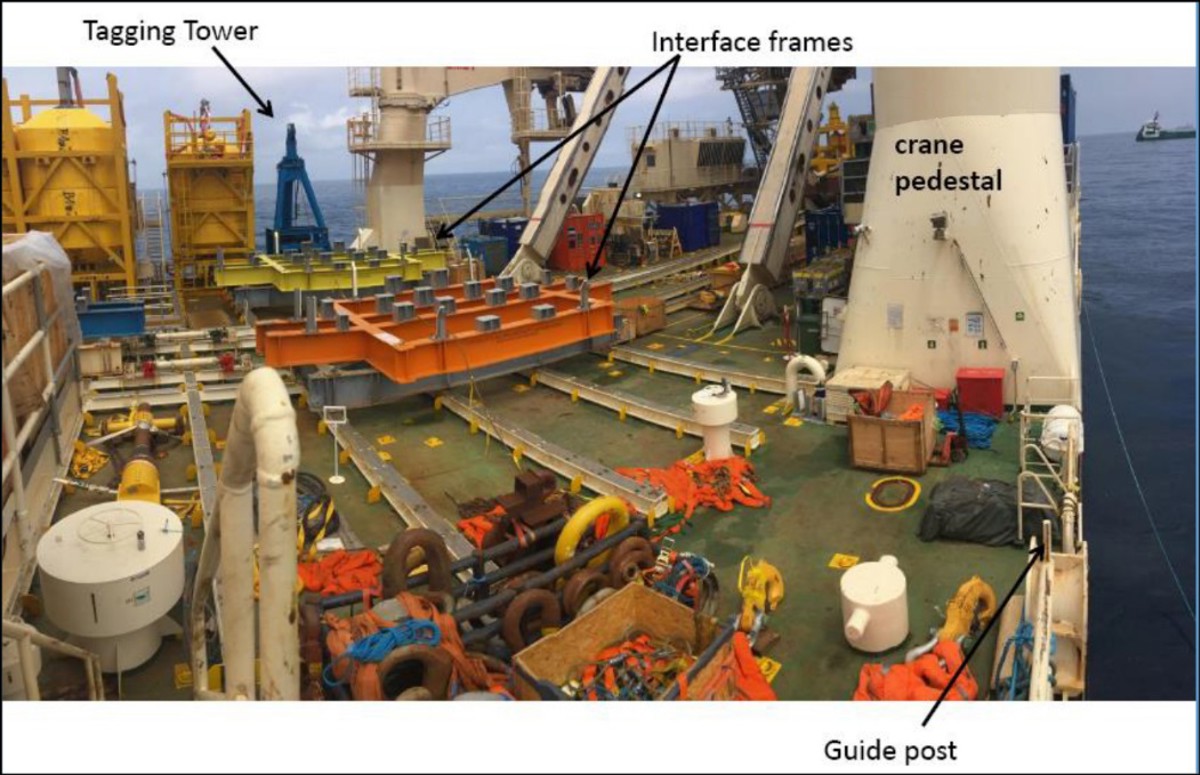

Figure showing worksite after incident

Our member’s investigation revealed the following:

- Direct causes:

- uncontrolled movement of wire when it became taut

- injured person ‘in the line of fire’

- Possible underlying causes:

- lack of concentration or failure to pay attention to the slack of the wire at the critical moment

- injured person was the only person watching the activity

- the task was perceived as preparatory work – there was a lack of personnel/supervision

- the order to stop was received too late. The winch operator may have been surprised or confused

- the winch was at constant tension – but the tension settings and/or pressure indication were unknown until the wire went into tension

- poor design of the winch panel: the winch hydraulic power unit (HPU) and emergency stop were initially next to the operator but had been relocated to make more space. The emergency stop was on the HPU, which was a 10m walk (not in a straight line) away from the control panel in a remote location

- the winch operator used unknown pressure to pay in, then moved the stick to neutral when he received the all stop, which applied the brake and locked the tension in the wire

- there was incomplete familiarity and inadequate training for the personnel in the use of this type of winch in constant tension mode

- variations in tension in the wire were created by the relative movements of the two vessels, which were connected together by the wire

- The following preliminary root causes were identified as:

- lack of attention/concentration, lack of supervision and lack of additional support and organisation

- failure to intervene at the critical moment

- poor risk perception – the risks in this specific task, with this specific level of crewing, were not identified

- poor design of winch control panel and HPU

- inadequate training with this winch and HPU operation, leading to a lack of understanding on how to use the equipment safely.

Actions, recommendations, and lessons learnt:

- technical inspection of all the potentially impacted areas

- function test of the winch

- review and update risk assessment

- further appropriate training for these particular types of winches to raise awareness

- ensure sufficient personnel are available to make any given operation safe

- relocate emergency stop to appropriate location

- ensure personnel:

- always intervene when they see an unsafe act or condition

- always perform a UK Health & Safety Executive (HSE) toolbox talk and work with a permit or safe system of work

- never perform tasks for which they are not trained and competent.

Members should be aware that IMCA has published a safety promotional video – In the line of fire.

Related Safety Flashes

-

IMCA SF 13/15

21 September 2015

-

IMCA SF 07/14

13 May 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.