Two dropped object near misses

- Safety Flash

- Published on 22 June 2018

- Generated on 18 July 2025

- IMCA SF 13/18

- 3 minute read

Jump to:

Incident 1 – Wooden block laying in top of main hoist block

During a voyage in good weather conditions, the Captain decided that the vessel would sail with the cranes secured on deck. On the second day of the trip, the Captain was looking at the main hoist block of the forward crane, which was secured at the same height and just behind the bridge, when he noticed a 30cm long piece of 10×10 timber lying on the side of the hook.

The piece of timber was most likely placed there during a re-reeving operation some months previously, although the investigation could not confirm this and it may have been there even longer. The piece of timber was immediately removed.

What lessons were learned?

- Ensure that your work area is suitable for using loose equipment (lying on deck, platforms, gratings).

- Ensure that your work area is checked for loose equipment during your job.

- Ensure that your work area is cleared up after completion of your job.

- It is good practice to use a tool lanyard when working at height with tools.

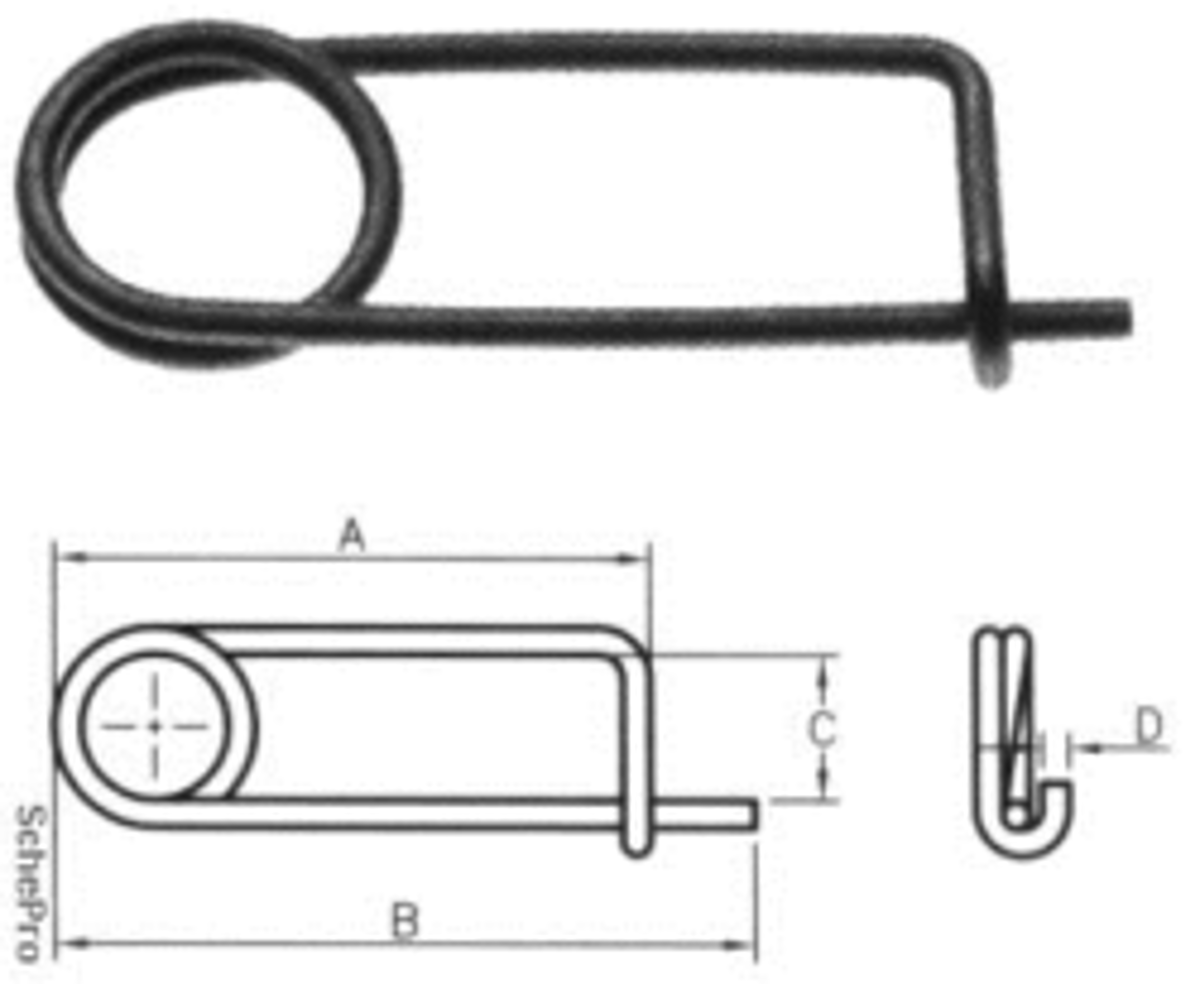

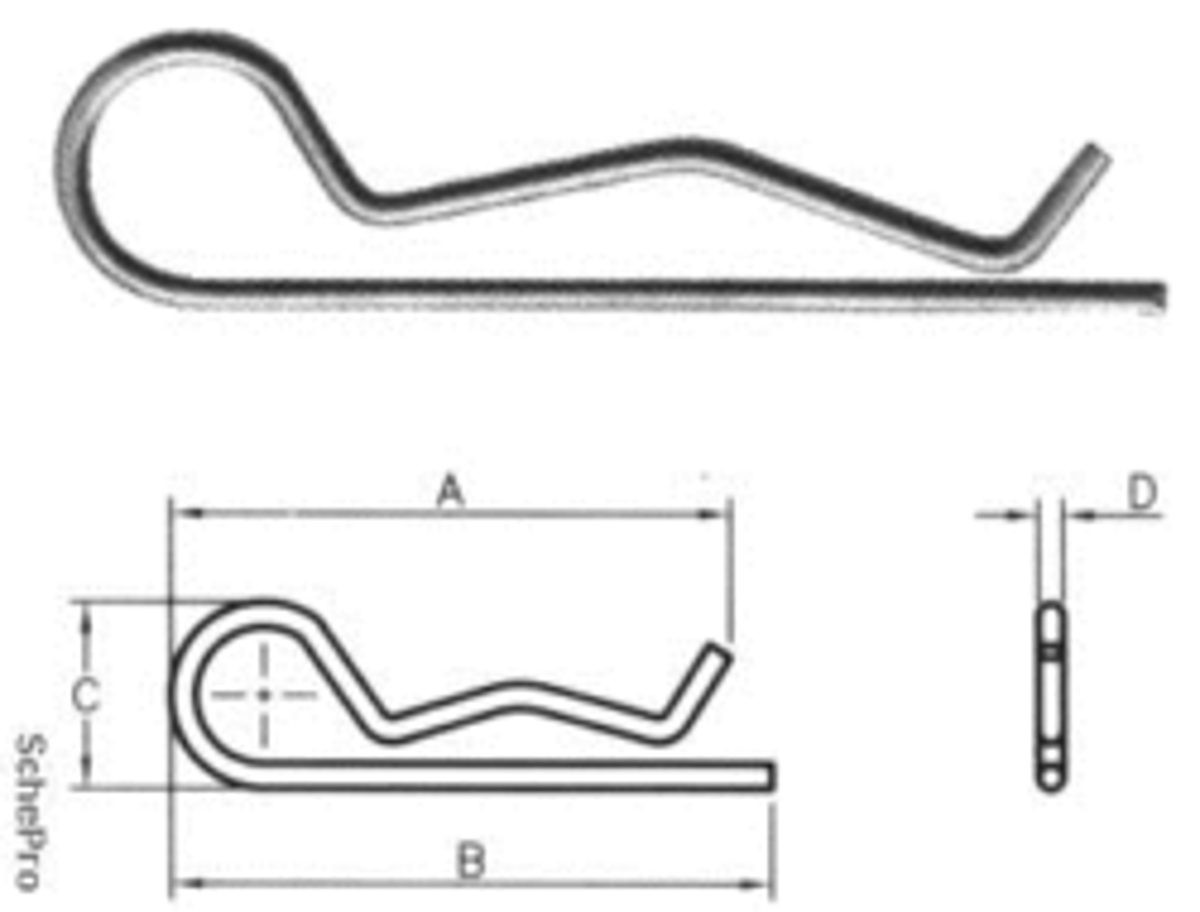

Incident 2 – Safety pin falls out of lifting beam

Whilst disconnecting lifting gear from a large piece of subsea equipment, which had been loaded onto deck, it was noticed by the crew that a securing pin on the load was more than half out of position. The lifting gear consisted of a large beam and two further spreader beams. The grommets used for these spreader beams were secured with the securing pin, in turn secured with a safety pin. A few minutes later, the securing pin was touched by a steering line attached to the main beam, causing the securing pin to fall out and drop 15m onto deck. No-one was nearby where the pin landed; the loose pin had been spotted and the area cleared beforehand.

What went wrong? What were the causes

After discussing this incident with the crew, it was clear that the pin was secured with a safety pin of the correct size. What was not known was if the safety pin was still in good shape and not bent open or damaged in any other way. Also not known was if the safety pin fell out of the securing pin by itself (gravity) or if the steering line somehow pulled/pushed the safety pin out.

There was no direct force on the securing pin by the grommets. Due to the rigging, the spreader beam was twisted; it was horizontal but twisted some 30 degrees around its axis. This caused the pin to slide out when the safety pin was gone. The safety pin was not found after the incident.

What actions were taken?

A new kind of safety pin was introduced:

Members may wish to refer to the following IMCA guidance and safety promotional material:

- Avoiding dropped objects – safety pocket card

- Working at height – video (see also Working at height)

- Technip DROPS – video

- Safe lifting (IMCA HSS030)

Related Safety Flashes

-

IMCA SF 26/17

20 October 2017

-

-

IMCA SF 11/17

22 May 2017

-

-

IMCA SF 08/11

27 July 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.