MSF: Corrosion in fire-fighting equipment

- Safety Flash

- Published on 31 May 2022

- Generated on 5 July 2025

- IMCA SF 13/22

- 2 minute read

Jump to:

The Marine Safety Forum (MSF) has published Safety Alert 22-09 relating to observations involving the CO2 firefighting system onboard a vessel.

What happened?

Significant corrosion was found during routine monthly inspection of the fixed CO2 system,. This resulted in it not being possible to insert the safety pin to isolate the cylinder during any maintenance.

What went wrong?

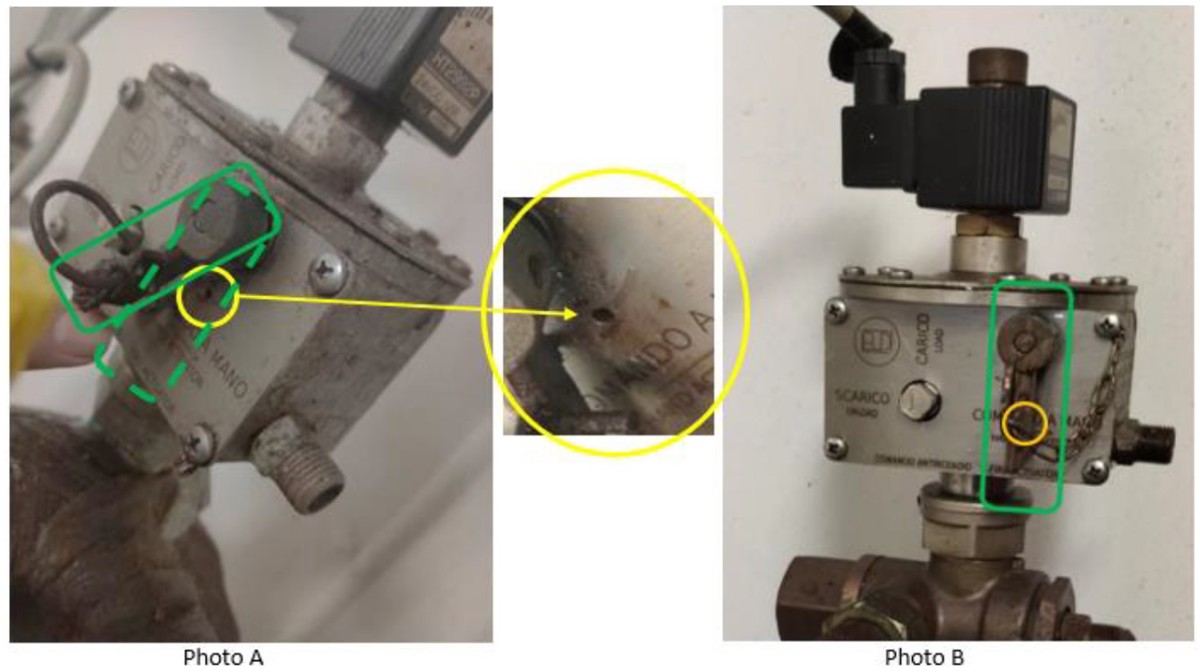

See Photo A below, which shows the safety lever and pin, unable to be positioned correctly in line with the pinhole. In Photo B after corrective maintenance and repair, it can clearly be seen that the activator arm, and therefore the safety pin aligns with the hole and can now be set to isolation for maintenance if required.

What went wrong (cont.)

The MSF notes that it cannot be stressed enough, that critical firefighting systems must be maintained and checked correctly and in accordance with manufacturer’s recommendations. This is to ensure that it is fit for purpose, and always ready to be activated or isolated correctly for vital maintenance.

The routine, regular maintenance of any safety critical system should be afforded the best attention, care and time as these may, if looked after correctly, save your life. Please show them the proper attention they deserve.

Related Safety Flashes

-

IMCA SF 10/22

21 April 2022

-

IMCA SF 04/19

12 March 2019

-

IMCA SF 06/18

19 March 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.