USCG: Exceeding electrical duty rating can lead to failure

- Safety Flash

- Published on 31 May 2022

- Generated on 6 July 2025

- IMCA SF 13/22

- 2 minute read

Jump to:

The United States Coastguard (USCG) has published Safety Alert 03-22 relating to the importance of verifying the condition and electrical duty ratings of the motor starter contactors in winch controllers for lifeboat and rescue boat launching appliances.

What happened?

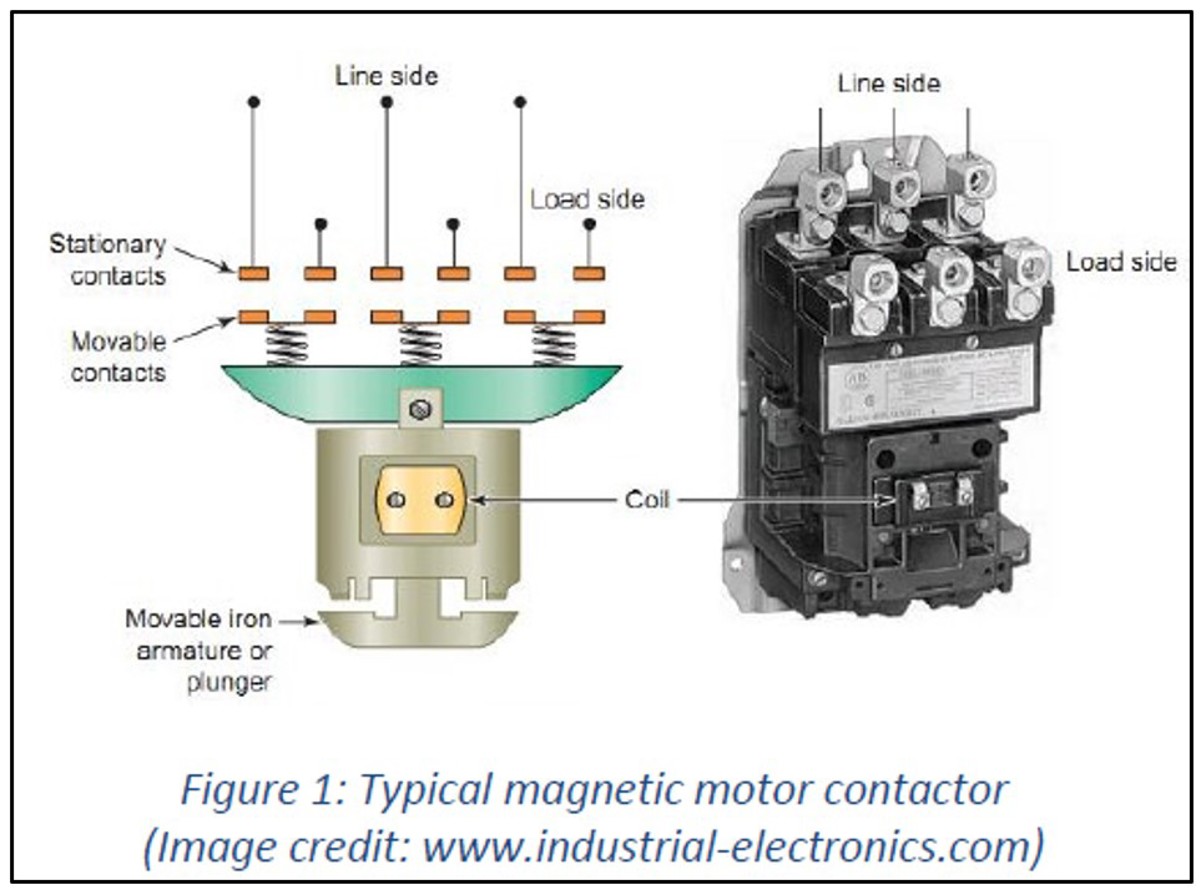

There was a failure during the routine maintenance and recovery of a rescue boat, where the electrical motor contactor for the winch motor failed in an energized position (i.e. motor in an “on” or “hoist” condition). This failure occurred when the contactors fused together due to exceeded duty rating. Metallurgical/post-event analysis ruled out any other failures with the contactor. The hoist button, emergency stop and limit switch circuits all failed to stop the winch from hoisting.

What went right?

Crew were able to secure electrical power via the 480-volt main breaker at the winch controller before the boat contacted the davit, avoiding serious damage and injury to personnel.

What went wrong?

The USCHG noted that analysis found that the contactors were not rated for intermittent cycling (start and stop sequences) of the winch and the contactor manufacturer had issued technical guidance on the issue of welded contacts. Intermittent cycling is a common practice during recovery of a lifeboat or rescue boat into the stowed position. A winch may be cycled after the boat has cleared the water to verify release gear condition prior to continued hoisting, possibly cycled several times during long hoists to reduce pendulum motions of the boat and cycled at approach to davit guides/stops. While commonly employed for a safe recovery process, intermittent cycling may exceed design and duty ratings of the electrical components.

Actions

The Coast Guard “strongly recommends that owners, manufacturers, operators and service providers, do the following:”

- Verify condition of winch motor contactors and replace any contactors that show signs of excessive wear, overheating, or welding.

- Verify the duty cycle ratings of lifeboat and rescue boat davit electrical components and compare those ratings to recommended and commonly-practiced boat recovery procedures/processes.

- Verify the design of the davit safety devices (i.e. emergency stop and limit switches) to see if they will secure electrical power to the motor in the event of welded contacts.

- Implement training for all personnel that operate the davits to ensure awareness related to electrical duty cycles and actions to isolate power in the event of a welded winch motor contactor.

Related Safety Flashes

-

IMCA SF 05/21

11 February 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.