Near-misses during diving operations

- Safety Flash

- Published on 9 June 2017

- Generated on 13 July 2025

- IMCA SF 14/17

- 2 minute read

Jump to:

Two near misses have occurred during diving operations.

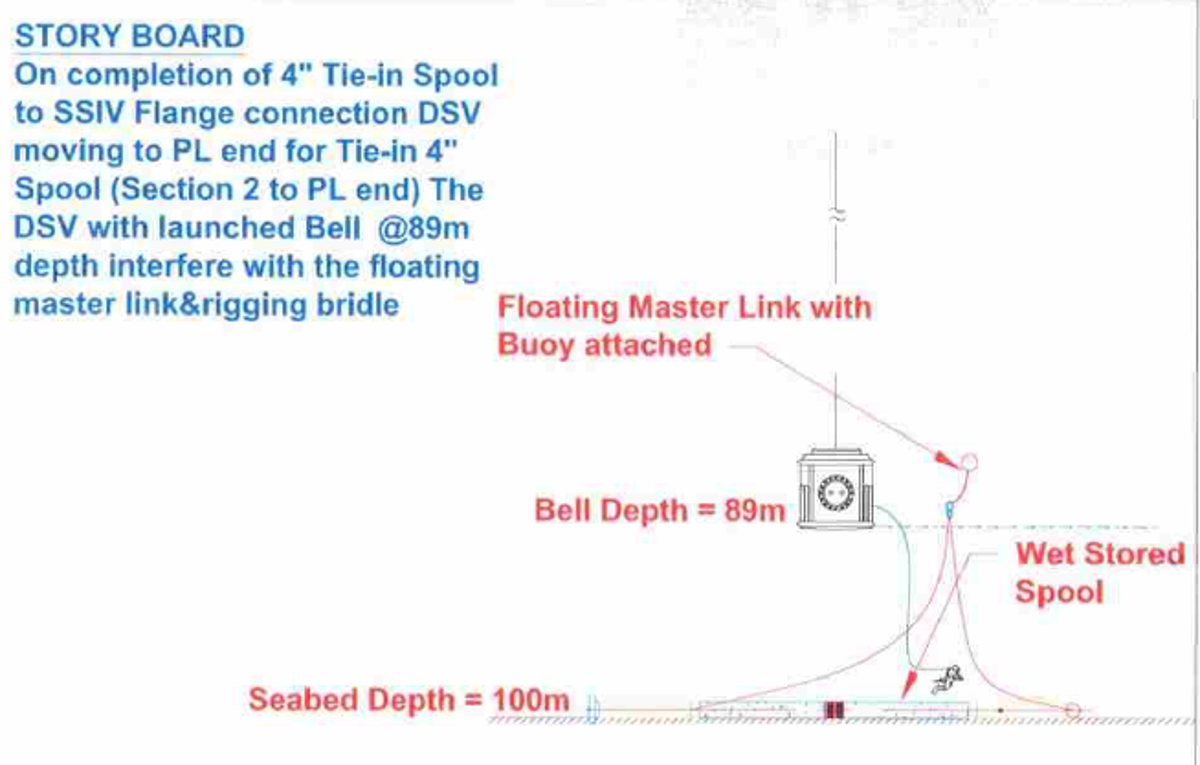

Incident 1: Diving bell nearly carried into subsea lifting equipment

During a bell run at 90 msw a task was completed and the diving support vessel (DSV) needed to relocate to a pipeline end. The move was started with the diver on the bell clump. He called an ‘all stop‘ when he saw the wire rope and four-part lifting bridle approaching the bell.

The vessel move was stopped and a new path to the next job was plotted. The DSV was relocated safely and work continued. There were no injuries and there was no damage to equipment.

Our member noted the following:

- There was no information available as to the depth of the buoys.

- There was added risk of umbilical entanglement when the divers passed unknowingly through the wire lifting slings.

- An ROV was deployed to the worksite and found buoys at 13 m above seabed. The bell was being held at 90 msw (10 m above seabed).

Incident 2: Subsea dropped object – stud bolt dropped to seabed

A stud bolt 3½” x 1015 mm was dropped to the seabed from the vessel side whilst attempts were being made to secure it to a device being prepared for subsea use. Dive control immediately alerted divers on the seabed, who were working on a pipeline flange 16 m away from the drop point. The divers cleared out from the job and the bolt landed without harming anyone or anything.

Subsequently a safety stand-down was held at the next bell turnaround. It was arranged for further items to be deployed in a dedicated tool basket.

DROPS online have published a handy two-page reference on subsea dropped objects which can be found on the Drops online website.

Related safety flashes

-

IMCA SF 18/13

20 December 2013

-

IMCA SF 14/06

12 December 2006

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.