Lost time injury (LTI): Gangway deployment

- Safety Flash

- Published on 23 October 2009

- Generated on 6 July 2025

- IMCA SF 15/09

- 3 minute read

Jump to:

A Member has reported an incident in which a person suffered a broken leg during gangway deployment.

What happened?

Prior to arrival at the quayside, a vessel’s double sectioned gangway (see Figure 1) was lowered and extended, in readiness for use, in accordance with onboard procedures.

Approaching the quayside, the bridge was informed that berthing plans for the vessel had changed. The change of berth required the use of a different gangway and the bosun was instructed to recover the now partly deployed gangway. The bosun and an able seaman (AB) started work on this task but failed to follow established procedures.

The recovery procedure required the gangway to be initially lowered to allow tension to come off the lifting wires and at the same time allow the securing pins to be removed for stowing, before then raising the gangway back up to the stowed position.

However, the bosun and the AB started to remove the securing pins without first lowering the gangway to take the tension off the lifting wires. The AB removed the inboard pin as this was not under tension and therefore easily removed by hand. The outboard pin was stiff because of the tension on the lifting wires. A crowbar was used to exert pressure on the lower section of the gangway, to allow the outboard pin to be removed. During this process, both the bosun and the AB were standing within the steps of the gangway, as shown in Figure 2.

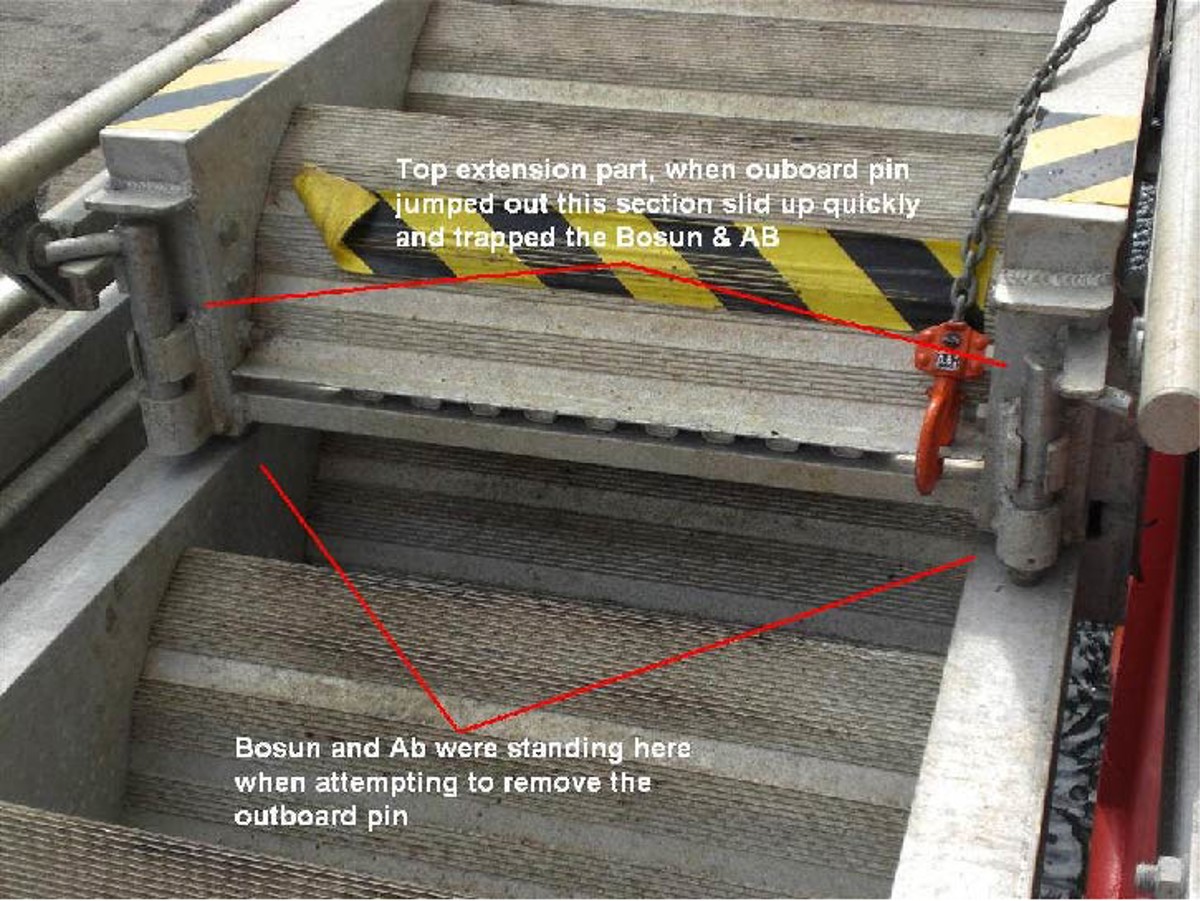

Top extension part: when outboard pin jumped out this section slid up quickly and trapped the bosun and able seaman. The bosun and able seaman were standing here when attempting to remove the outboard pin.

Figure 2 – Area of entrapment – (top arrows) Top extension part: when outboard pin jumped out, this section slid up quickly and trapped the bosun and able seaman (bottom arrows). The bosun and able seaman were standing here when attempting to remove the outboard pin.

The expectation was that the pressure applied by the crowbar to the lower section of the gangway would loosen the outboard pin, which could then be removed by hand. Instead, the outboard pin, with the pressure released, jumped out. Because there was still tension on the lifting wires at the lower end of the gangway, the lower extension section of the gangway slid quickly upwards, trapping both the bosun and the AB by the legs.

Urgent assistance was requested and both men were subsequently released by using a lever hoist to relieve the pressure. During subsequent medical attention it was discovered that one of the workers had a serious fracture of the leg. He was taken to hospital ashore.

This extremely serious incident could have been avoided entirely by following the correct procedures.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.