Space heater caught fire

- Safety Flash

- Published on 1 July 2019

- Generated on 12 July 2025

- IMCA SF 15/19

- 2 minute read

Jump to:

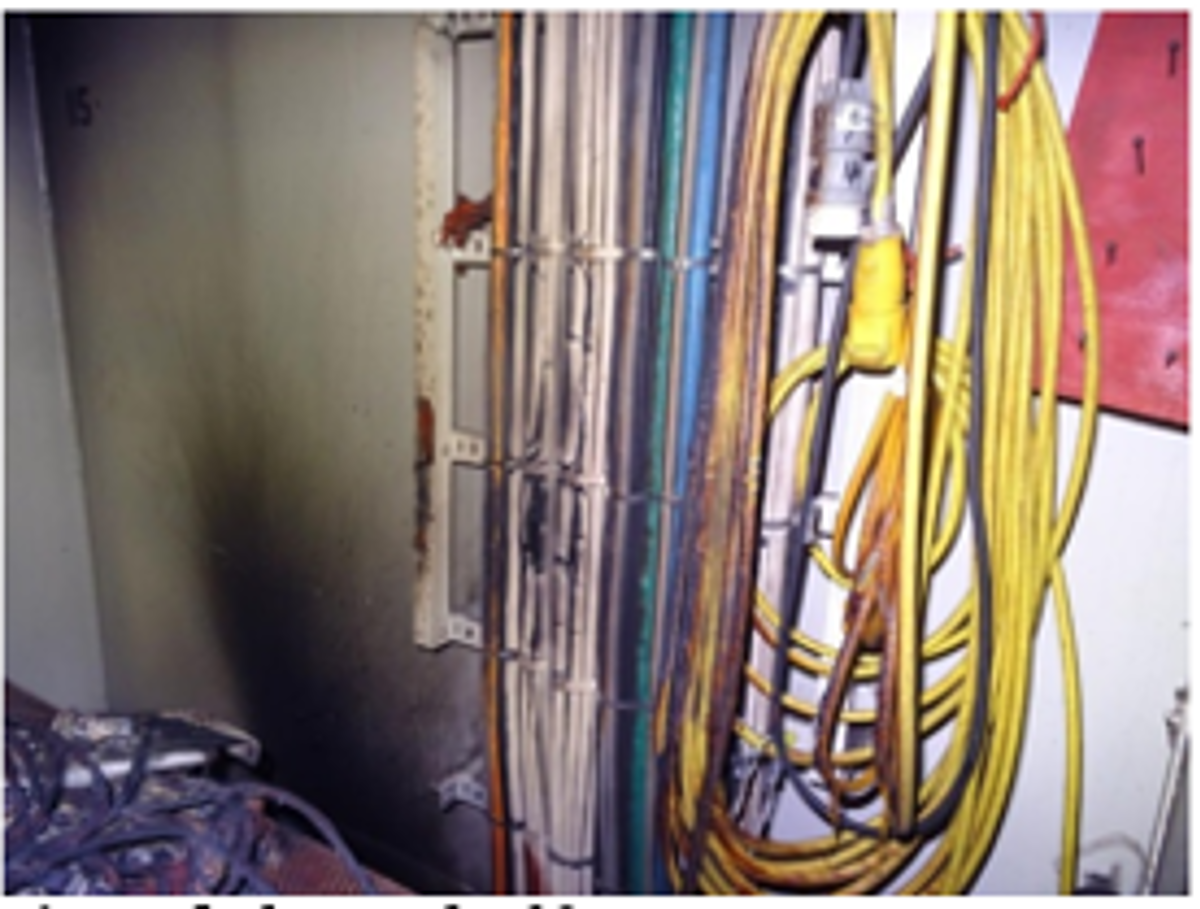

A space heater and some loose equipment caught fire.

What happened?

An area had been washed down as part of a housekeeping activity. As a precaution, electrical heaters were switched off and protected from the cleaning water by tarpaulins. The next area to be cleaned was being inspected by the cleaning supervisor and electrician on watch to ensure precautions were in place (e.g. electrical heaters switched-off and protected from washing water etc).

During this inspection, the cleaning supervisor informed the electrician on watch that the washing of the first area was complete. Upon completion of the inspection of the next area, the electrician remotely switched on the heater in the first area to assist with drying.

However, whilst washing activity in the first area was complete, the housekeeping was not. There were still three portable lights on top of the heater and it was still covered by tarpaulin. The three portable lights, tarpaulin and some adjacent electrical cables all caught fire.

What went wrong? What were the causes?

- Assumptions: when the cleaning supervisor informed the electrician that the washing of the column was finished the electrician assumed that this included housekeeping.

- Didn’t check: the electrician switched on power to the heater without physically verifying that the protection had been removed.

Recommended action

- CHECK! Always physically verify that worksites are returned to a safe condition after completion of work.

- Never ASSUME that the site is safe without making sure.

- Never re-energise equipment before making sure that it is safe to do so.

Members may wish to search the IMCA Safety Flash incident database for themselves for words such as assume, verify, check.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.