Inhalation of toxic fumes during hot work

- Safety Flash

- Published on 2 June 2021

- Generated on 12 July 2025

- IMCA SF 15/21

- 3 minute read

Jump to:

Two crew members were exposed to toxic fumes resulting in dizziness, headaches, difficulty in breathing, and low blood oxygen levels

What happened?

The incident occurred during hot work when thruster couplings were being replaced. This was on a vessel experiencing problems with Tunnel Thruster (TT) couplings due to installation/commissioning issues during a new build.

It was decided to replace the thruster couplings, and a detailed step by step work plan was executed, including Permit to Work, work planning meeting, risk assessment, and emphasis on “stop work authority” during the toolbox talk.

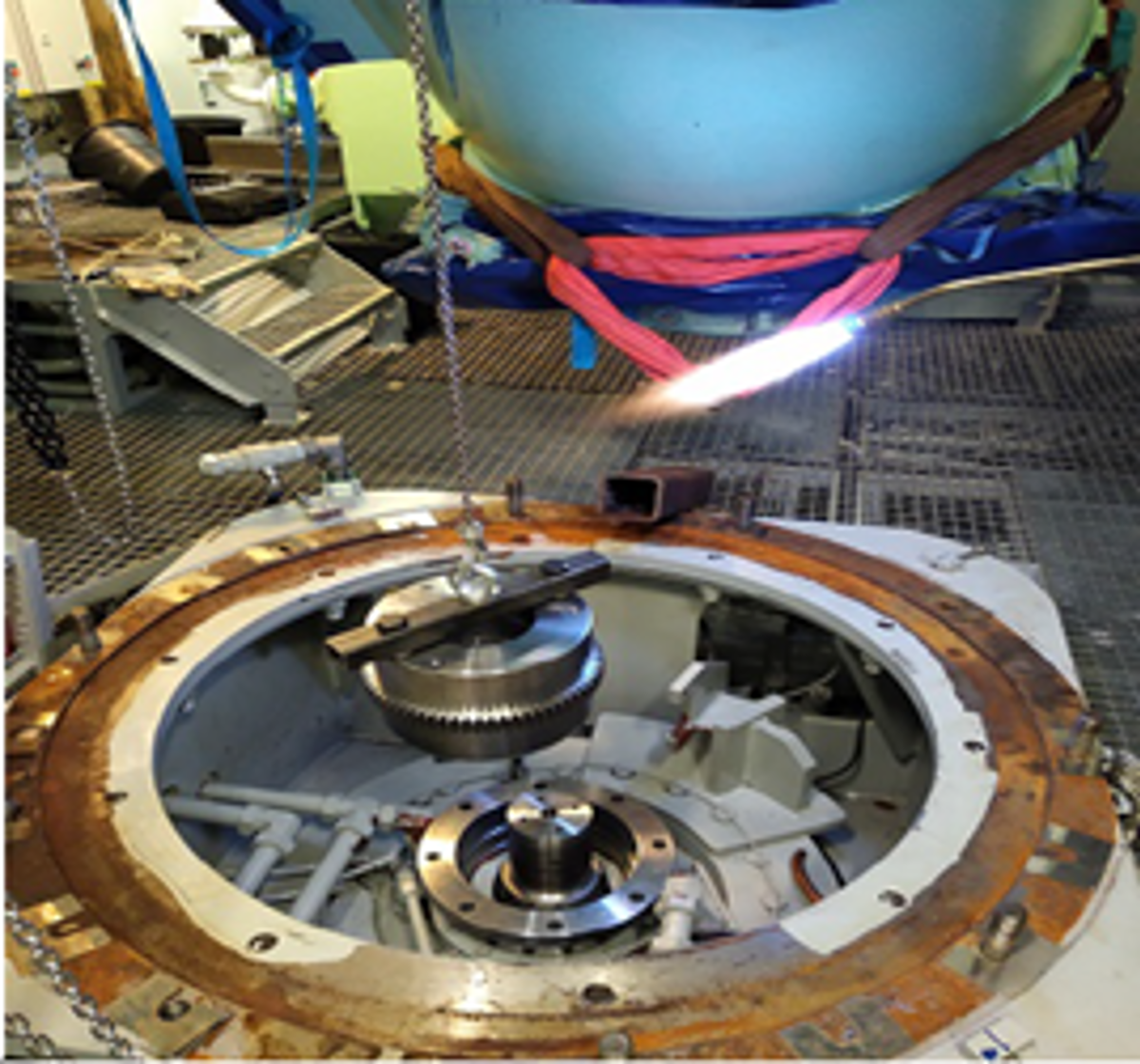

Coupling hub during the heating process

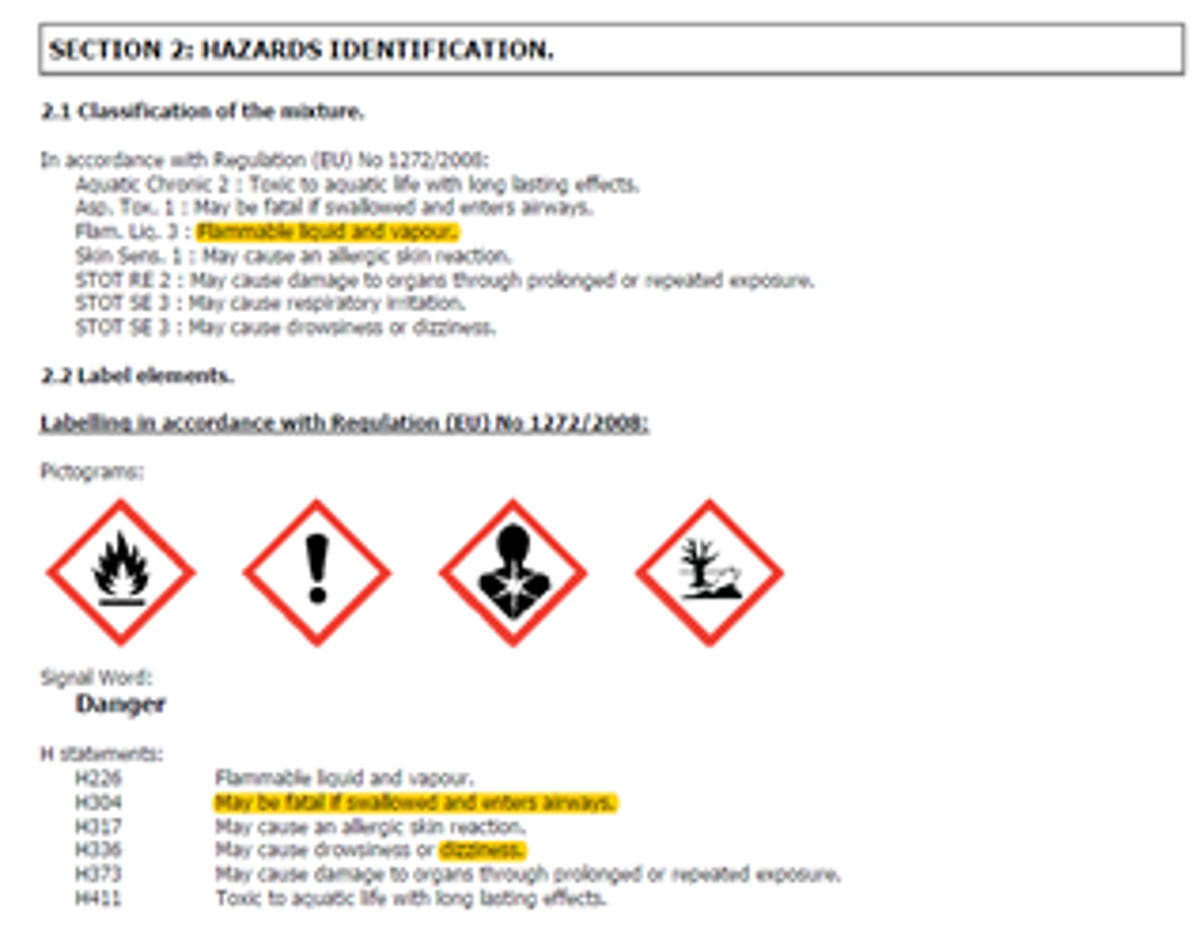

Section 2 of safety data sheet for anti-rust chemical used: Rust Keeper 555 (ADR)

In order to change out the thruster coupling, the component had to be heated to 120-150 °C. The temperature in the bow thruster room (not a confined space area) was 32-35 °C and the ventilation set up assessed in the planning was to mitigate the heat and provide some cool airflow through the room. The coupling was heated up and when it reached the required temperature, this led to a release of toxic fumes from the anti-rust chemical used on it.

The chemical used as anti-rust was unknown to the crew and no SDS had ever been provided by the supplier of the coupling. The supplier’s service engineer, who was required to be onboard supervising the task, appeared to be unaware of the type of anti-rust chemical on the coupling.

The exposure to the chemical was felt later in the day. Two of the crew members experienced a heavy chest, dizziness, headache, difficulty in breathing, and low blood oxygen levels. Based on consultation with topside medical support, the two crew members were sent ashore for medical evaluation and treatment.

What went wrong?

- Lack of awareness of anti-rust chemical agent, leading to intoxication of two crew members.

- No SDS was available for the anti-rust chemical agent and the service engineer was unaware of chemical toxicity.

- A work instruction included a requirement for the component to be clean before installation (wiped); however, the installation instruction/procedure did not mention any chemical, nor any special product to be used, nor a requirement for a thorough clean of the component before installation.

What went right?

There was a detailed step-by-step work plan, including:

- Permit to Work

- Work planning meeting

- Risk assessment

- Emphasis on “stop work authority” during the toolbox talk.

What was the cause?

Our member noted that a lack of knowledge of the spare part (thruster coupling) being coated with the toxic anti-rust agent, and subsequently lack of removal before heating and installation, lead to the intoxication of crew members. Ventilation was used for air cooling rather than toxic air extraction

Actions / lessons learned

Be aware of the possibility of toxic anti-rust agents and therefore ventilation should always follow a risk assessment process where identification of potential risks such as intoxication should be considered first.

Related Safety Flashes

-

IMCA SF 02/20

10 January 2020

-

-

IMCA SF 05/17

3 March 2017

-

IMCA SF 08/03

3 July 2003

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.