Hand injury: Injection of hydraulic fluid

- Safety Flash

- Published on 10 November 2009

- Generated on 10 July 2025

- IMCA SF 16/09

- 2 minute read

Jump to:

IMCA has received information about a hand injury caused by leaking pressurised hydraulic fluid on a drilling rig.

What happened?

A person was searching for the source of a small hydraulic leak. The leak was located and a request made for the hydraulic pump to be shut down so that the damaged hose could be replaced. The pump was duly shut down. Then the person involved placed his index finger (whilst wearing double gloves) over the damaged spot on the hose so as not to lose the location of the leak.

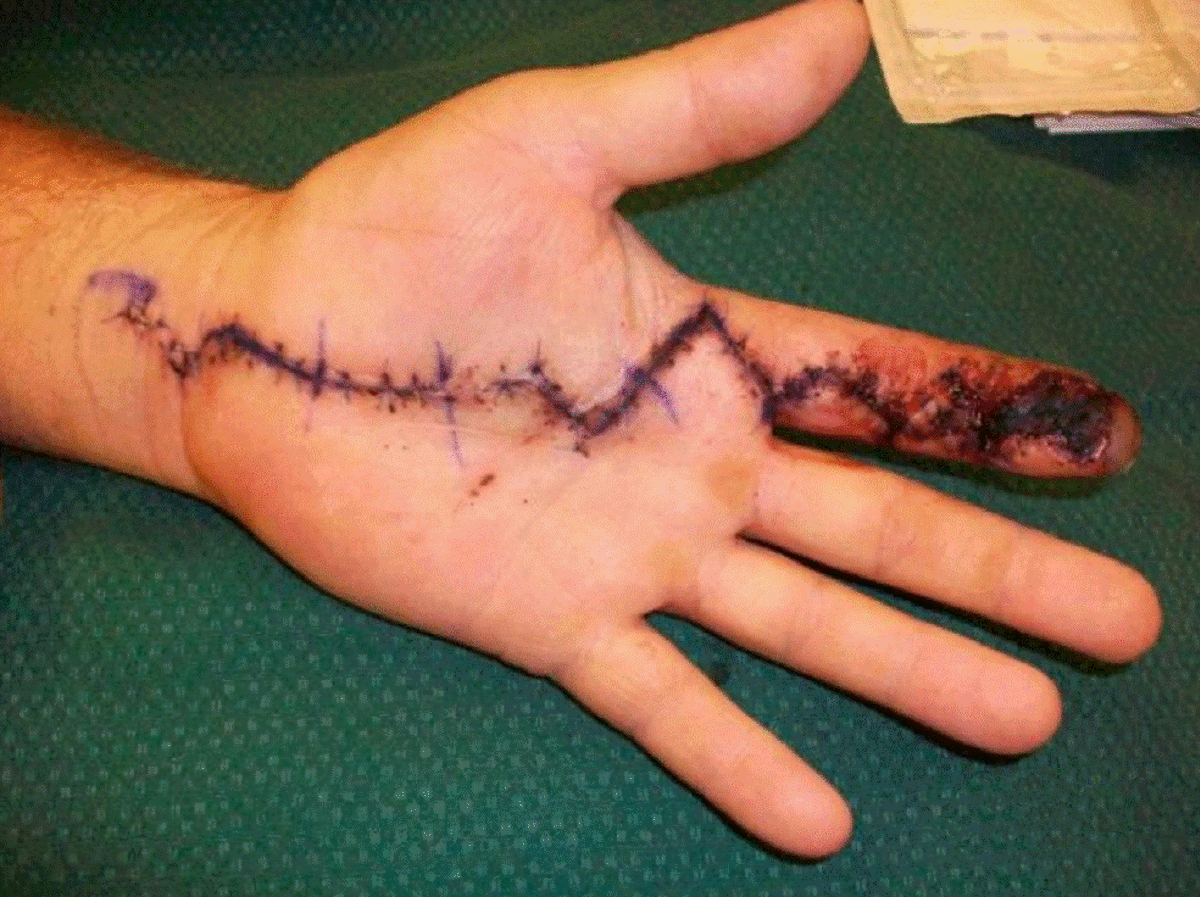

The person involved was unaware that hydraulic pressure remained on the system following shut down of the pump and that this pressure had actually increased for around two seconds after the pump shut down (owing to back pressure). Hydraulic fluid burst through the damaged spot on the hose and was injected through the double gloves into the person’s index finger. Surgery was required to find and remove the injected oil from the finger and hand of the person.

This incident serves as a timely reminder to maintain vigilance and awareness of the very serious potential hazards and risks associated with working with pressurised hydraulic fluid.

major surgery was required to track and remove the injected hydraulic oil from the person’s hand

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.