Maintenance of automatic external defibrillators (AEDs)

- Safety Flash

- Published on 19 November 2015

- Generated on 6 July 2025

- IMCA SF 18/15

- 1 minute read

Jump to:

During a recent audit, a Member discovered significant non-conformances pertaining to the storage and maintenance of AED.

What happened?

The consequences were potentially significant, and immediate re-assessment was undertaken of all such equipment at that member’s dive sites. AEDs should be available for immediate usage.

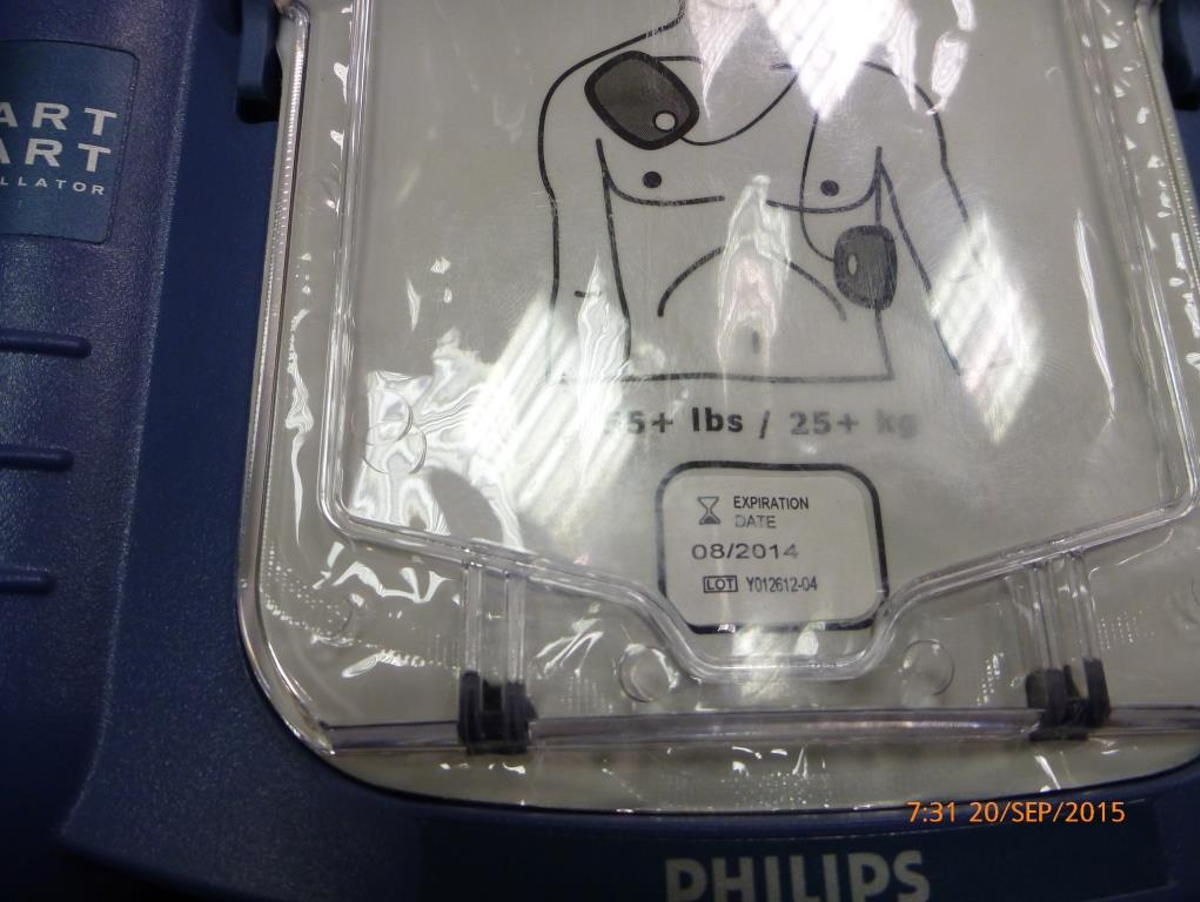

Our member’s audit process noted the following non-conformances:

Our member considers this to be a significant issue. Inspection of other sites revealed that in some cases batteries were removed or detached from the units. Removing or detaching the batteries from these units will prevent the unit being used for an additional sixty seconds, and lessens the chances of survival for the patient.

Our Member took the following actions:

- Confirmed that the battery was fitted in accordance with the manufacturer’s instructions.

- Confirmed that all equipment associated with the AED was ‘in-date’.

- Tested the readiness of AED in accordance with the manufacturer’s instructions.

- Appropriately trained personnel conducted a familiarization session on use of the AED with all of the crew.

- Ensured that the maintenance of the AED was added to the appropriate planned maintenance system.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.