Dropped pipe incidents with potentially fatal consequences

- Safety Flash

- Published on 10 September 2018

- Generated on 6 July 2025

- IMCA SF 20/18

- 2 minute read

Jump to:

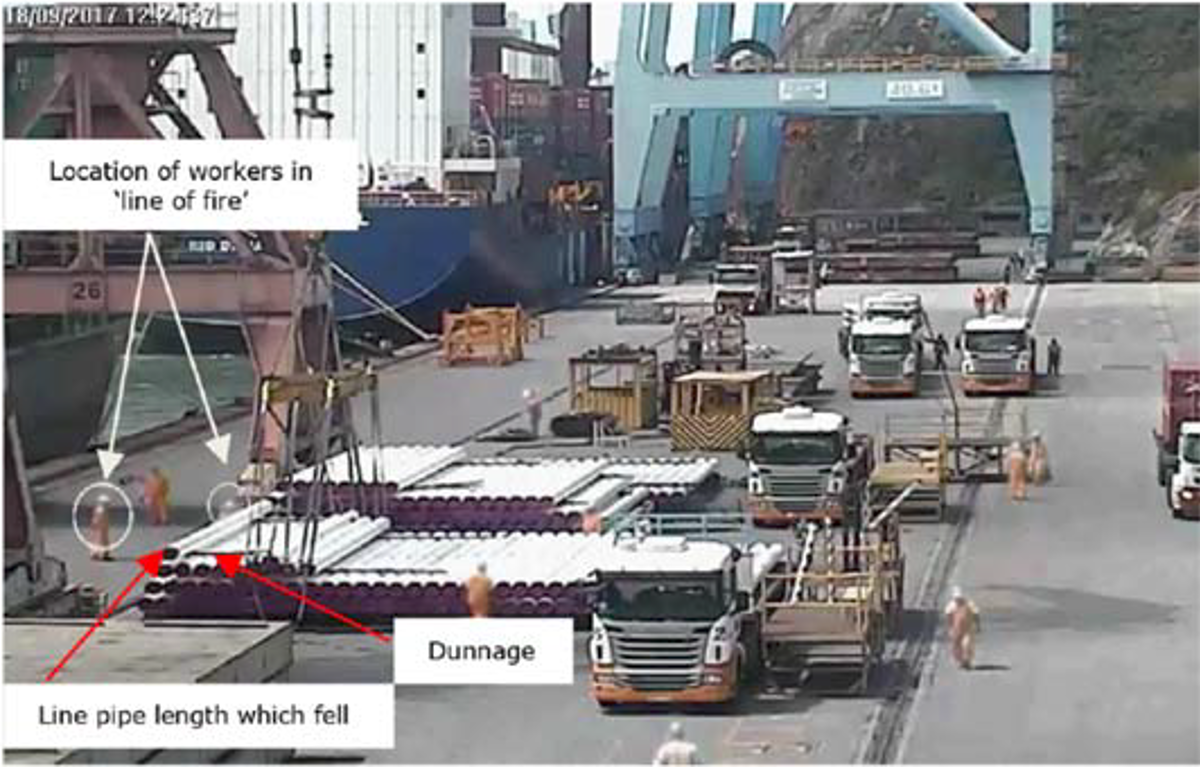

During line pipe load out operations, three high potential near miss incidents occurred involving quayside crane lifting operations

What happened?

All of the incidents had the potential for fatal consequences from line of fire situations. Two of the incidents resulted from the line pipe being dropped from the quayside storage positions, and the third as a result of line pipe contact with the ship’s hold bulkhead which could have caused the pipe to drop.

In all of the incidents, site activities were being directly supervised and controlled by our member’s subcontracted line pipe supplier. The operations involved a chartered heavy lift vessel, subcontracted by the line pipe supplier, to undertake the pipe load out activities.

What went wrong? What were the causes?

Our member noted the following:

- There was no work instruction available to detail the task and process of securing and lifting pipe from the quayside into the hold of the vessel.

- There was no requirement within the line pipe supplier’s management system to verify that their subcontractors executing the pipe load out understood and were experienced in the task, nor to verify the training and competency of those subcontractors.

- The communication process between the banksman and crane operator was not clearly understood (there was no documented process).

- The crane operator found it hard to see the banksman during the lifting operation, yet continued the lifting operation.

- The pre-job briefing did not cover all of the tasks to be conducted.

- There was a lack of experienced supervision at all stages of the pipe load out activities.

- The quayside slewing crane used was not as suitable for the task as the gantry crane, which was not always available for use.

What lessons were learned?

In evaluation of potential suppliers:

- A focus should be placed on the high-risk activities that bidders are proposing to subcontract out.

- Do not assume that suppliers are knowledgeable and experienced in all aspects of their contract.

Members may wish to refer to:

- IMCA HSS019 LR006 M187 D060 Guidelines for lifting operations

- IMCA HSS032 M221 Guidance on safety in shipyards

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.