Finger injury while setting up pipe cutting operation

- Safety Flash

- Published on 12 September 2023

- Generated on 12 July 2025

- IMCA SF 22/23

- 2 minute read

Jump to:

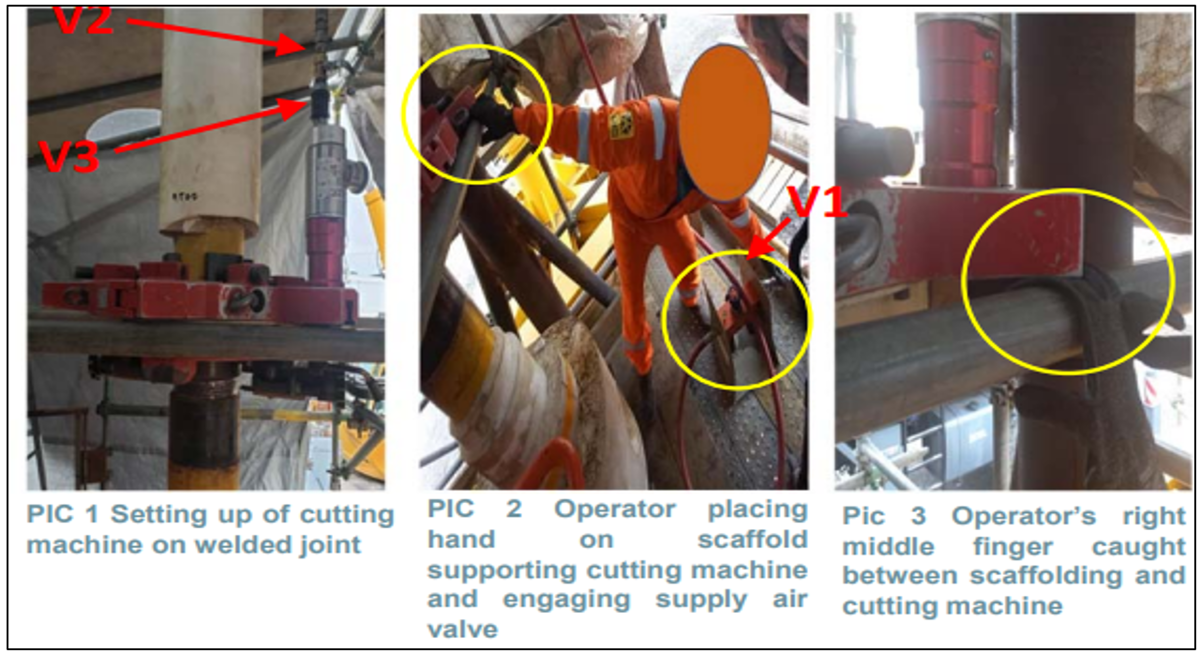

A crew member was setting up a pipe cutting machine in a vertical position to cut welding that was done on a jumper for repair, when they suffered a finger injury.

What happened?

The crew member opened a supply valve on an air caddy with his left hand, while his right hand was on a scaffold tube supporting the equipment, and suddenly the equipment moved.

The crew member got their right middle finger trapped in between the scaffolding tube and the lower part of the cutting machine protruding part.

What went wrong?

One of three valves in the machine was found to be defective during post-incident simulation. Company standing instructions required that the machine be turned manually during the setup validation or readiness check (to confirm its proper setup before energising it). This was not done.

The crew member intended to perform a setup validation check by energising the equipment. He closed the Inlet valve (V2 in photo), and then must have opened the Supply valve (V1 in photo) to perform the check. Due to the fault on the inlet valve (V2), as the Supply valve (V1) was opened, the inlet valve (V2) allowed air to pass and energised the machine causing it to rotate. As the machine rotated, it trapped his finger that was placed on the scaffold tubes.

At the time of event the injured person was on the working platform alone.

What was the cause

Our member’s view is that there were two causes:

- The method of work did not follow the standard procedure.

- The injured person put his hand in an unsafe place.

Lessons learnt

- Don’t take short-cuts – equipment operating procedures and manuals are there for a purpose and should be followed.

- Check that you – all of you – is out of the line of fire. Always ensure body parts are kept away from moving or rotating parts.

Actions

Our Member:

- Improved toolbox talks to increased awareness of unsafe positioning in this cutting operation and other tasks.

- Refreshed training in the use of this equipment for the operators.

- Improved procedures to make the task safer.

- Developed and implemented pre‐use checklist to cover inspection of cutting machine and accessories (air supply hoses and valves).

Related Safety Flashes

-

IMCA SF 04/21

2 February 2021

-

-

IMCA SF 13/19

4 June 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.