Dropped pallet during loading of stores

- Safety Flash

- Published on 13 September 2016

- Generated on 18 July 2025

- IMCA SF 23/16

- 5 minute read

Jump to:

A Member has reported an incident in which a pallet shed its load during lifting operations, resulting in 900 kg of groceries falling 7 m to the deck below.

What happened?

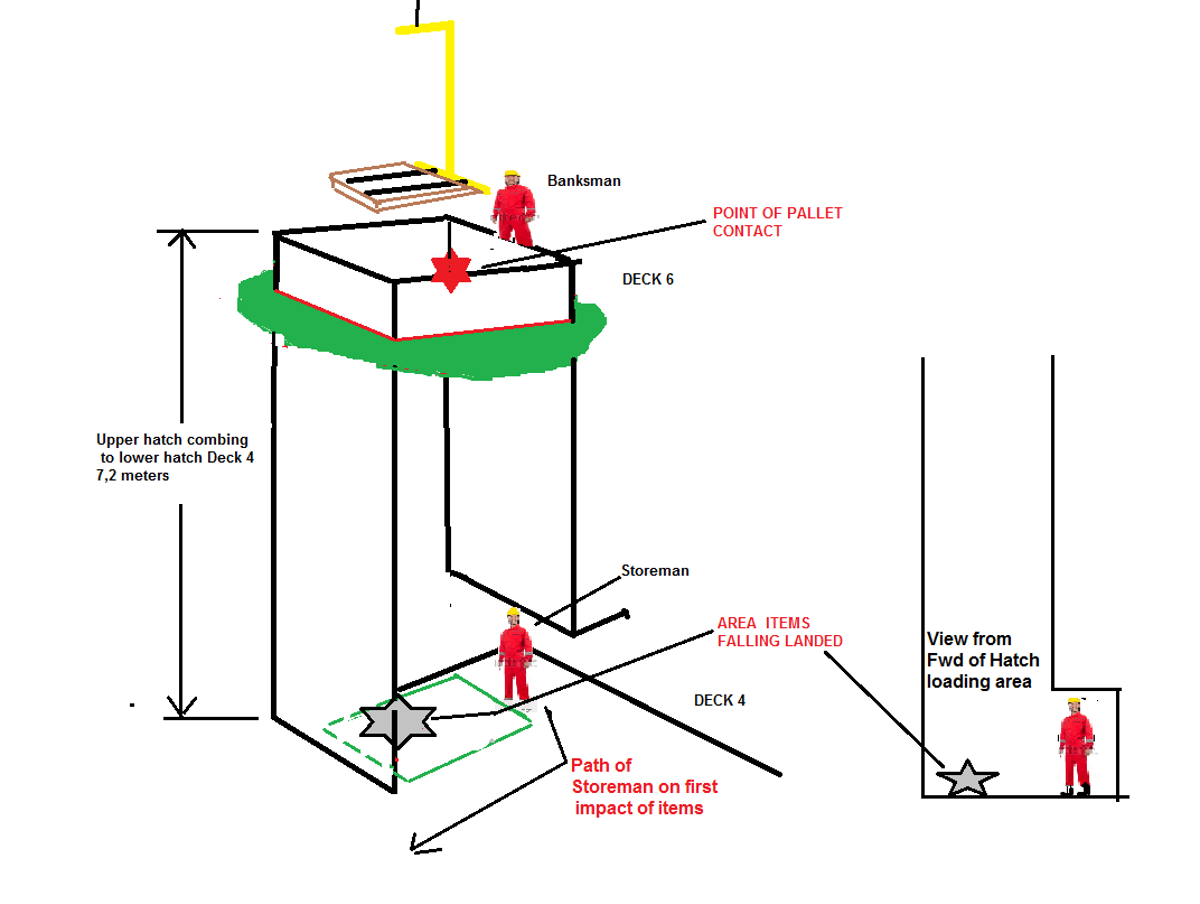

The incident occurred during a ‘routine’ lifting operation from quayside to vessel. Whilst attempting to lower a pallet laden with stores through a deck hatch, the load contacted the corner of the hatch, damaging the pallet. The cellophane wrapping split near the bottom, and the majority of the 902kg contents fell 7.2m to the deck area below. The front right corner of the pallet was hanging off but did not fall.

Although the pallet contained multiple items, the individual weights of the goods dropped were significant. Had a person been under the load and struck by a falling item, the potential severity could have resulted in a fatality.

No one was harmed during the incident however, the storeman who was receiving the load at the designated landing site had run inadvertently slipped on cooking oil which had spilled from the damaged supplies, causing him to fall to the deck onto his hands and knees.

Our member’s investigation revealed the following:

- Personnel responsibilities had not been adequately established at the tool box talk (TBT) before the lifting operation.

- A number of crew members had arrived on the worksite late, failing to attend the TBT. This resulted in confusion as to who was responsible for the load at what point during the lift.

- In preparation for the lift, and unlike the previous loads, the bosun neglected to use the load securing chain on the pallet lifting frame. This oversight had been noticed by the crane operator who did not report it – the crane operator felt it was his supervisor’s responsibility and did not want to challenge his superior’s action.

- A pallet lifting box was on-board the vessel. The pallet involved was too large for this box. Had the pallet lifting box been capable of accommodating the pallet in question, it could have prevented the incident.

- On lowering the pallet into the stores hatch, the crane operator was expecting instructions from the banksman who conversely believed that the crane operator had control at this stage. Because of the incorrect understanding and lack of control from the banksman, the load was lowered into the blind hole in one slewing motion and not in a staged progression – this did not allow for the load to be stabilised and centralised before it was lowered through the hatch.

- The risk assessment did not make reference to the practice of a staged progression.

- As a result of the above, the load had a sufficient degree of freedom to contact the side of the hatch and damage the pallet, resulting in the contents dropping to the deck below.

Our member identified the following causes:

- There was insufficient detail recorded in the lift plan and task risk assessment.

- Personnel responsibilities were not adequately established during the TBT.

- The load was not sufficiently secured on the pallet – a lifting chain was not used.

- The crane operator took no action when he noticed the pallet lifting frame chain was not being used.

- There was no pause above the hatch to secure and centralise the load before lowering.

The root cause was found to be complacency during ‘routine’ tasks.

The following contributory factors were noted:

- Self-imposed/perceived time pressures.

- No additional rigging was used to secure the contents of the pallet.

- Pallet lifting box held on-board did not fit the pallet size being used.

- Not all personnel involved in the operation attended the TBT.

- Culture-driven behaviours influenced the crane operator’s decision not to report, as he felt it was inappropriate to challenge his supervisor.

Our member required the following immediate actions:

- Ensure all personnel involved in an operation attend a toolbox talk (TBT) before taking part in the activity.

- The TBT should sufficiently outline roles & responsibilities of those involved.

- Reinforce the ‘stop the job’ philosophy to work teams prior to conducting an operation.

- Review lift plans and task risk assessments for ‘routine’ lifting operations, ensuring they are up to date and there is sufficient detail surrounding:

- control of loads

- roles and responsibilities of personnel involved

- securement of loads

- lifting of pallets

- ‘Line of Fire’ and confirmation of clear areas during blind lowering

- Review the method for securing pallet loads ensuring it is adequate for the proposed lift.

- When lowering through a blind hole, adopt a staged progression to the lift allowing for the load to be stabilised and centralised before lowering.

- Communicate with your work team that time constraints should not impede the safe progress of an activity. If there are concerns regarding time constraints and the viability of completing a task, this should be raised with the offshore management team or supervisor.

Related Safety Flashes

-

IMCA SF 14/15

2 October 2015

-

IMCA SF 05/11

29 June 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.