Damage to chain hoist subsea

- Safety Flash

- Published on 24 October 2022

- Generated on 4 July 2025

- IMCA SF 23/22

- 1 minute read

Jump to:

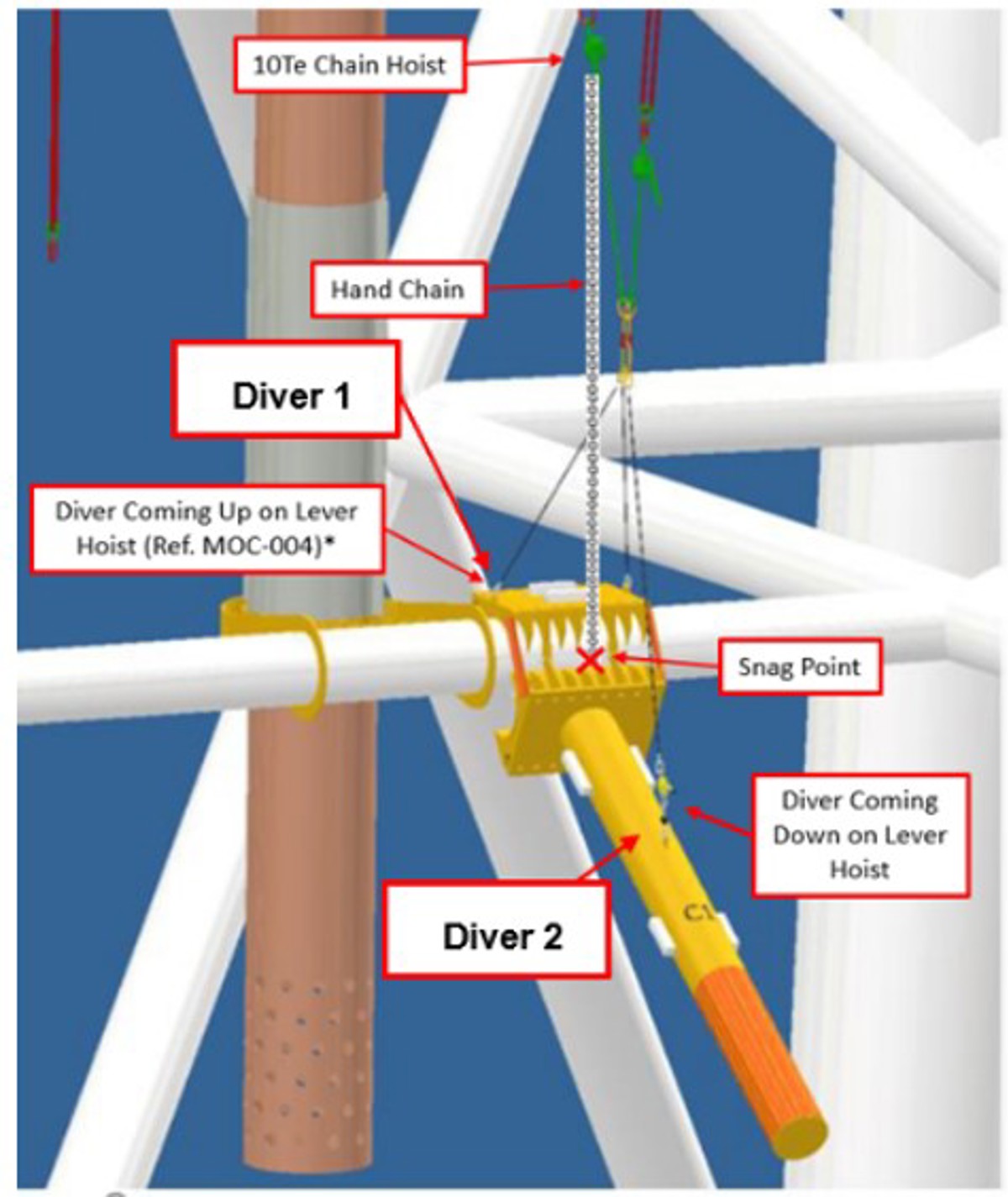

Whilst divers were lowering a large clamp for installation, the chain block used to centralise the clamp on the horizontal member became trapped in the hinge point on the clamp.

What happened?

The clamp was opened when it was noticed and damage to the chain link was observed. There was no damage to the clamp itself.

What were the causes?

- Although initial checks of the worksite were performed, checks were not frequent enough during the task of lowering and closing the clamp.

- Whilst the procedure did include a safety note on awareness around pinch points, however, it did not specify any checks the hoist chain or loose items of rigging.

- There was no prompt for entanglement or snagging hazards included in the dive team procedures.

The root cause was found to be that the procedures did not identify and highlight entanglement or snagging hazards.

What our member did

- Caused heightened awareness around snagging hazards when operating chain lever hoists.

- Reviewed procedures to include a prompt for the use of chain / lever hoists identifying the risk of entrapment of chains.

Related Safety Flash

-

IMCA SF 17/22

14 July 2022

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.