Fire in welding fumes extraction system

- Safety Flash

- Published on 25 August 2020

- Generated on 5 July 2025

- IMCA SF 25/20

- 2 minute read

Jump to:

What happened?

In a shore-based workshop facility, the filters inside a welding fume extraction unit ignited whilst in operation.

On investigating an initial smell of burning, smoke was seen escaping from the welding fume extraction system at the rear of the workshop.

Smoke ingress into the workshop activated the smoke alarm and the workshop was safely evacuated.

The system was shut down and initial attempts using portable CO2 extinguishers at the base of the unit was unsuccessful, as the fire progressed upwards through the filter banks.

On arrival the emergency services extinguished the fire through direct water application and cooling.

What were the causes? What went wrong?

Following initial investigation and discussions with the supplier it was found that the filters were blocked which allowed metal particles to build up, oxidize on the filter surfaces, heat up and eventually lead to a fire.

The unit was well within its annual inspection period and nothing related to filter replacement was highlighted at the previous inspection.

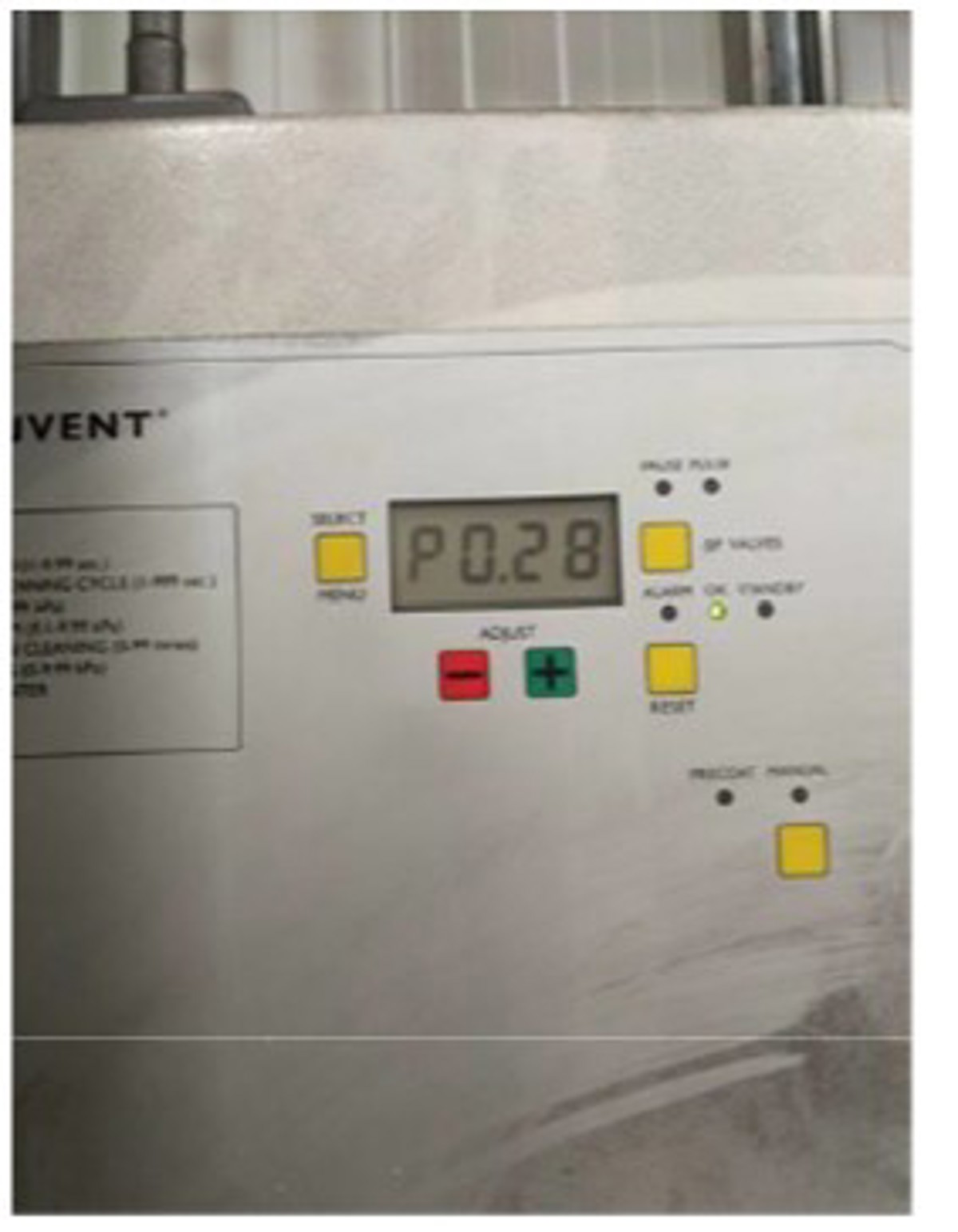

The supplier advised that blocked filters are indicated by a reading of 2.0 or above on the unit’s display (2000 Pascals). As an example, the display from an operational unit is shown here. This indicates 0.28 (280 Pascals) showing it is nearly new and well within the limit.

Actions

Where similar systems are used, check the display for high or excessive pressure readings as outlined in the manufacturer’s instructions and ensure that this check is included in regular operational and maintenance checks.

Related Safety Flashes

-

IMCA SF 19/19

12 August 2019

-

-

IMCA SF 04/19

12 March 2019

-

IMCA SF 07/11

19 July 2011

-

IMCA SF 01/11

27 January 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.