MAIB: mv Teal Bay mooring fatality

- Safety Flash

- Published on 8 November 2022

- Generated on 4 July 2025

- IMCA SF 25/22

- 3 minute read

Jump to:

The UK Marine Accident Investigation Branch has published Report 9/2022 relating to a mooring deck fatality on board a cargo vessel in August 2021.

Of interest in that this may have made the investigation more difficult, was that it was conducted remotely as access to the vessels, shore authorities and port involved was not possible due to COVID-19 travel restrictions. The remote investigation also limited the evidence that was directly available from the local authorities.

What happened?

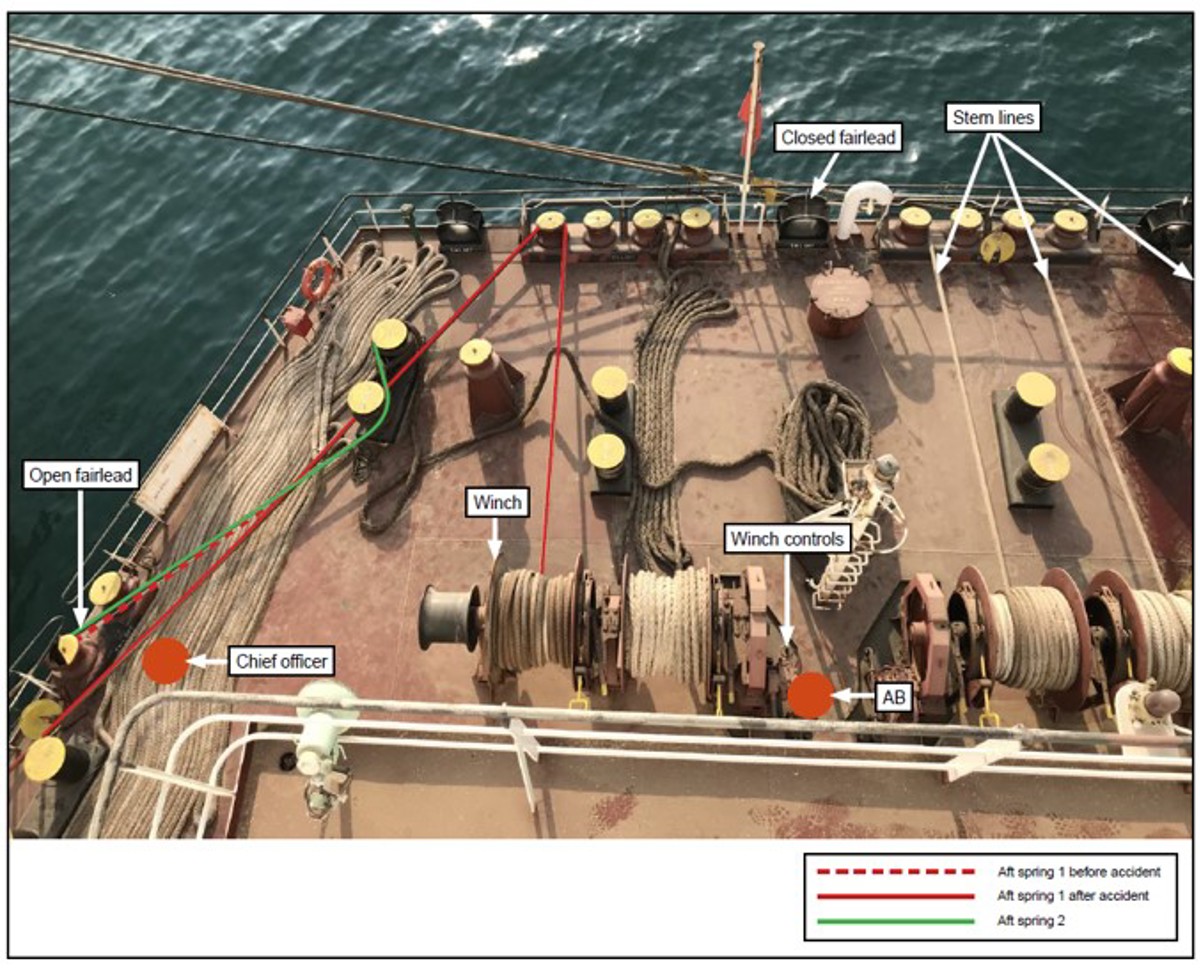

The Chief officer was fatally injured when he was struck on the head by a tensioned mooring line that sprang out of an open roller fairlead. Teal Bay was loading grain when moored alongside an anchored bulk carrier. The mooring line was being used to pull Teal Bay forward and it sprang free when its lead angle became too great for the open fairlead to restrain it.

The MAIB notes: the Chief officer was struck because he was standing in a hazardous area close to a mooring line under significant tension. The operation to move Teal Bay forward had not been risk assessed and was undertaken with insufficient crew. The use of an open roller fairlead was inappropriate during a ship to ship transfer operation where a freeboard differential between the two vessels was foreseeable and created the hazard of a high lead angle on mooring lines.

Showing mooring arrangement (dotted line indicates position of aft spring 1 before the accident)

What went wrong?

- The mooring line sprang free because the fairlead in use was open and the lines had developed a hazardous upward lead during Ship-to-ship cargo operations as the difference between the vessels’ freeboard increased.

- Leading two lines through the same fairlead restricted the space available and almost certainly contributed to the loss of spring line 1 containment.

- The number of crew assigned to carry out the warping operation was insufficient and almost certainly influenced the Chief officer’s decision, which went unchallenged, to stand in a hazardous area.

- There was insufficient planning for both the mooring and the warping; this happened because, for both evolutions, there was a lack of time available to plan and the crew was unfamiliar with the operation.

- Despite the crew’s efforts and the assistance of a tug, it took over two hours for the casualty to be seen by a medical professional. Given the severity of his injuries, it is unknown whether the delays in the Chief officer receiving medical attention had any bearing on his death; however, the lack of coordination by the parties involved in organising the medical response created delays that lessened his chances of survival.

Recommendations and actions taken

- Fleetwide safety alert to highlight the safety issues raised.

- Additional safety training with crew, including modules on safe mooring operations and ship-to-ship transfer.

- Planned to remove open fairleads and replace them with a closed type or universal type of fairlead.

- Reviewed and SMS procedures and risk assessments.

Related Safety Flashes

-

IMCA SF 20/19

23 August 2019

-

-

IMCA SF 12/14

14 July 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.