LTI – rigger tripped over quayside obstacle in the dark and fell

- Safety Flash

- Published on 3 December 2018

- Generated on 10 July 2025

- IMCA SF 26/18

- 2 minute read

Jump to:

A rigger walking along the quayside tripped over an obstacle, and in the resulting fall suffered fractures to both wrists, a bone in his hand and his elbow.

What happened?

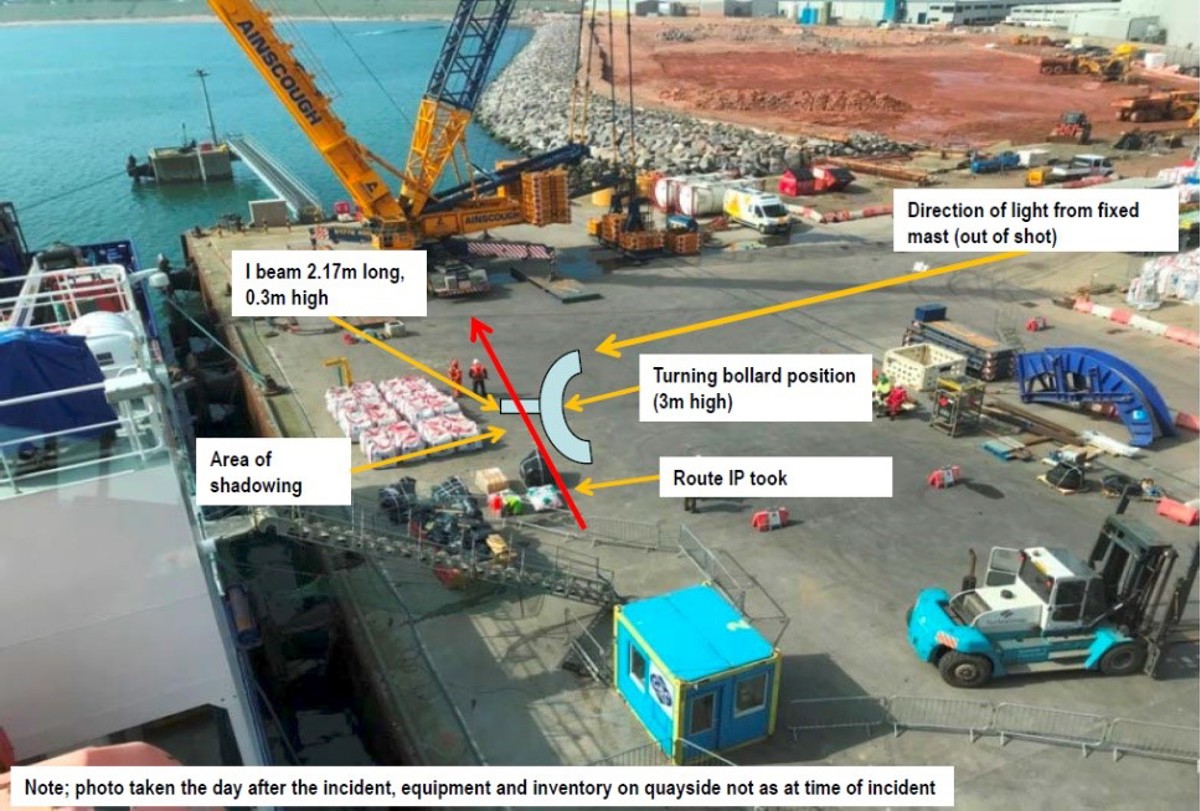

The incident occurred at night during a project mobilisation. The rigger walked down the gangway and onto the quayside to help the deck foreman. He tripped over a grillage I-beam fabricated to the turning bollard that was awaiting lift onto the vessel.

What went wrong? What were the causes?

- The rigger did not take sufficient care or recognise the hazards and risks associated with walking through an area where equipment had been stored for loading.

- Other personnel involved in quayside operations and handling of equipment did not intervene or fully recognise all hazards and risks associated with activities and equipment.

- Identified control measures for slips, trips and falls were not applied to quayside operations.

- The QA/QC checks performed were not fully effective as they focused on dimensional and integrity checks rather than occupational safety hazards.

- The grillage ‘I’ beam was not identified as a potential tripping hazard during inspection or handling activities.

- The grillage ‘I’ beam was in shadow and there had been no consideration of additional onsite lighting.

- Responsibility for management and control of quayside operations was not clearly defined.

What actions were taken? What lessons were learned?

- Ensure that shift handovers clearly identify who has responsibility for operations on the Quayside. Before starting work, at the start of each shift the Quayside should be checked by those responsible for hazards and to ensure it provides a safe place of work.

- Consider provision of further portable lighting as required during mobilisation.

- Ensure principles of dynamic risk assessment are applied to day-to-day routine operations; this provides opportunity to continually assess the surrounding environment for hazards and adapt to change throughout the shift.

Members may wish to refer to the following incidents:

- Guidance on safety in shipyards (IMCA HSS032)

Related Safety Flashes

-

IMCA SF 02/18

23 January 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.