Hand injury from portable hand-held angle grinder

- Safety Flash

- Published on 15 September 2020

- Generated on 14 July 2025

- IMCA SF 27/20

- 2 minute read

Jump to:

What happened?

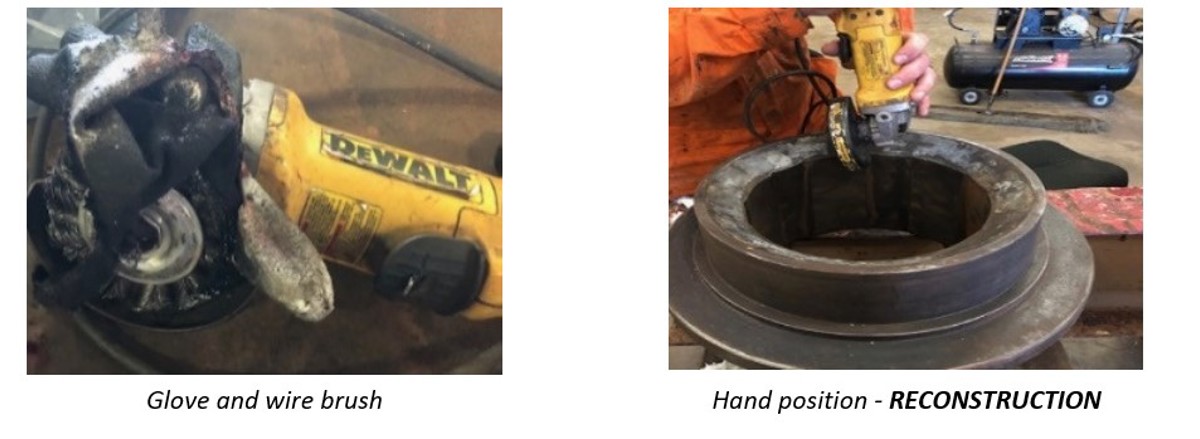

A worker was injured whilst cleaning equipment using a portable handheld angle grinder fitted with a wire brush. The rotating brush caught an edge and kicked into the worker’s gloved left hand. The glove was pulled into the rotating wire brush resulting in a deep abrasion to the hand.

What were the causes? What went wrong?

Our Member’s investigation determined:

- The task risk assessment was incomplete.

- The grinder was being used without the side grip handle fitted.

- No consideration was given to where to place the hand relative to the rotating brush.

- Given the operator’s position, the grinder could not be used safely.

- The operator should have moved to the other side of the component to complete the task, and deployed the grinder in a horizontal position.

- The operator should have moved to the other side of the component to complete the task, and deployed the grinder in a horizontal position.

- There was no formal power tool / abrasive wheel training in place.

- There was inadequate supervision of the task.

Lessons learned

- Equipment should be safe and without risks to the operator (that is, complete, with safeguards fitted and free from defects). [This is a regulatory requirement in many places].

- Appropriate supervision is essential.

- Reliance was placed on experience and ‘on the job’ training rather than on formal training and competence evaluation.

Actions

- Task risk assessment amended to include all hazards and control measures.

- Angle grinder side grip handle obtained and fitted and its use made mandatory as company policy.

- Review of power tool/abrasive wheels training and competency evaluation requirements.

- Supervisors’ responsibilities discussed and reaffirmed.

See also:

- Are YOU prepared to work safely videos:

- IMCA short video – Watch your hands

- IMCA short video – Grinding wheel safety

Incidents reported to IMCA involving grinders, can be investigated from the Safety Flash archive.

Related Safety Flashes

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 03/05

1 March 2005

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.