Failure of personal isolation procedures: Crane became damaged when it was used inappropriately

- Safety Flash

- Published on 18 December 2023

- Generated on 15 July 2025

- IMCA SF 29/23

- 3 minute read

Jump to:

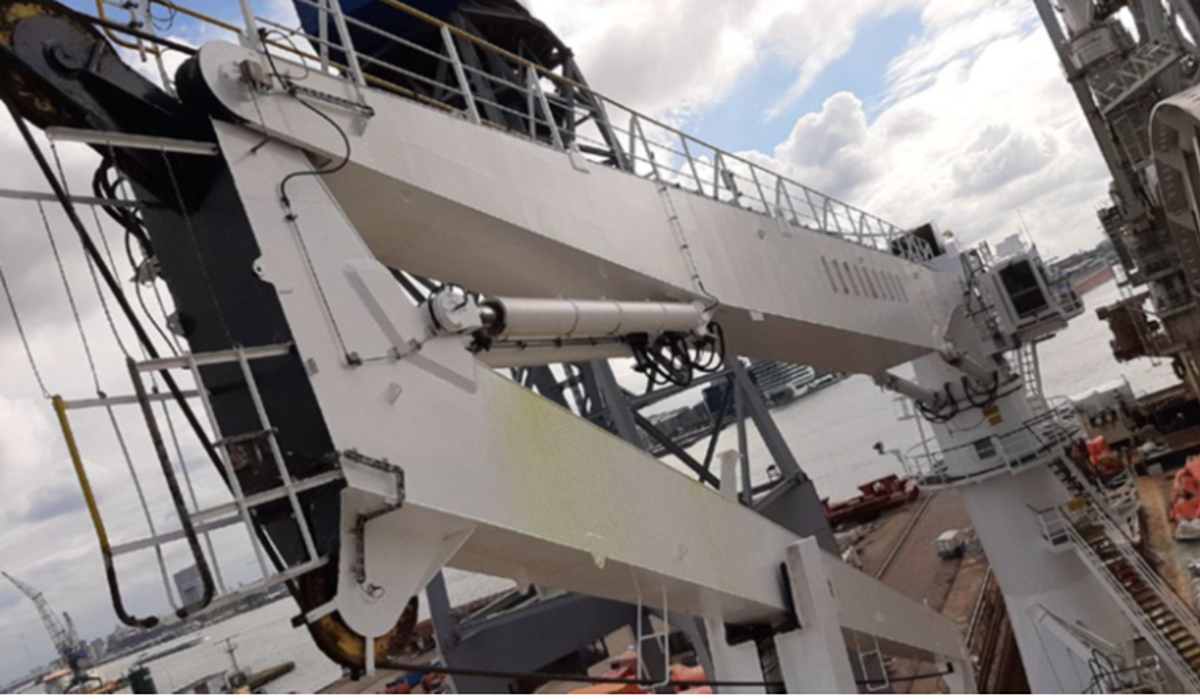

On a vessel in dry dock, a crane, which had been isolated for many days for work to be conducted by a third party, was used by crew unaware that the crane was out of use for maintenance.

What happened?

The crane was damaged as a result, leading to increased maintenance time and cost.

A “personal” isolation of the crane had been removed to allow a third party to function test the crane.

A leak was found on the hydraulic system and work was being conducted to repair the issue.

However, crew members not involved in the maintenance of the crane had a task to do which needed a crane, and they decided to try and operate the crane, resulting in damage.

What went wrong?

Our members’ internal procedures for personal isolations were not adequately applied. It was noted by our member that this was not the first time this had occurred. The previous example had led to a crew member being exposed to 930 Vdc.

A personal isolation is used when a single person conducts low risk work on a piece of equipment. They cannot be used by more than one person and cannot cross shifts. A personal isolation was used inappropriately in this case as it was applied over a number of days by more than one person working on the equipment.

Contributory factors

-

The vessel was in dry dock and there was a weight limit of 5 tonnes on the crane. Operation of the crane was required to be communicated with the bridge to ensure vessel stability on the blocks.

-

The scope of the crane maintenance work was non-routine and involved risks of pressurised hydraulics and movement of heavy machinery.

- A Permit to Work (PTW) should have been used but was not used:

- The task was not adequately risk assessed in accordance with the requirements for when a Permit to Work (PTW) was required.

- The lack of a PTW was a missed opportunity – had the PTW process been followed, the errors which led to the failure of personal isolation, would have been spotted.

- To follow the isolation procedure flowchart which would have captured the sanction to test control loop.

- The task was not adequately risk assessed in accordance with the requirements for when a Permit to Work (PTW) was required.

Personal isolation should only be used by persons directly involved in a low risk activity and within the duration of one shift. The isolation of the crane was not low risk and there was an injury potential from exposure to pressurised hydraulics. Also, third party personnel were not authorised to work using personal isolation at company worksites.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.