DP2 supply vessel

- DP Event

- Published on 25 August 2021

- Generated on 30 June 2025

- DPE 03/21

- 5 minute read

Incident

Jump to:

After ‘daily checks’ on the running engine, engineers accidently activated the emergency stop which resulted in an immediate blackout.

Overview

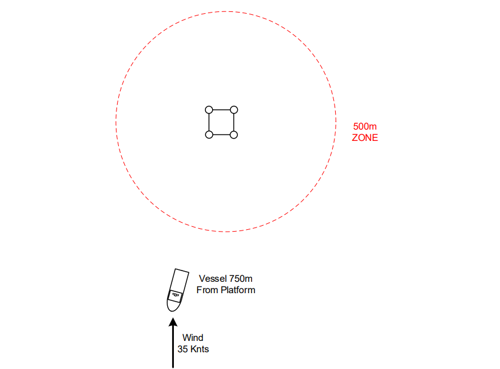

A DP2 supply vessel was sitting on stand-by outside a 500m zone of a gas platform awaiting orders for cargo operations. Whilst outside the 500m zone and on standby, the vessel closed the bustie and reduced to a single generator and three out of the five available thrusters.

The vessel heading at the time was 185 degrees, the DP current was 0.8 knots - 290 degrees and the wind force was 30-40 knots - 180 degrees. Three thrusters were selected online and one of four generators were also online, the remaining three generators were ready and on standby.

There was one single redundant group by virtue of a closed bustie and a single connected generator. Two DGNSS, three gyros, three VRS and three wind sensors were online and selected into DP Control.

Note that the vessel was upwind of the platform and in a ‘Drift on’ position. The area was difficult to find a safe drift off position due to location of several other platforms and sandbanks with shallow water.

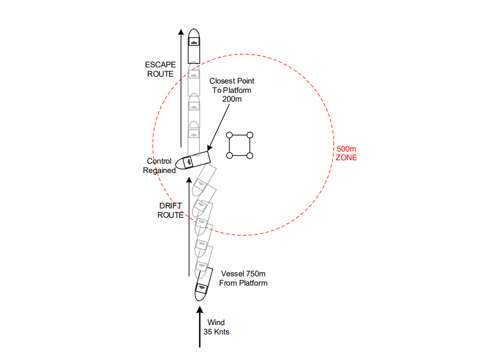

Whilst carrying out ‘daily checks’ on the running engine the engineers accidently activated the emergency stop, this resulted in an immediate blackout. The vessel started to drift towards the 500m Zone and it was observed that the wind speed was increasing. As shown below.

As the vessel started to drift, the standby generators started and connected, however blackout recovery was a manual process that required re-setting of breakers and starting of critical machinery. As a precautionary measure an anchor was deployed that held the vessel until full manoeuvring control of the vessel could be gained. The

anchor held the vessel 200m from the platform and once thrusters were back in control, the vessel exited the 500m zone.

Causal factors

Below is a list of causes that together led to the incident highlighted above:

- The vessel was configured in such a way that a single failure would exceed the Worst Case Failure Design Intent of the Vessel Task Appropriate Mode (TAM).

- It was assumed that because the vessel was outside the 500M zone situational awareness could be relaxed and TAM could be applied.

- A protection cover for the local emergency stop on the running connected generator was missing allowing for the inadvertent activation of the emergency stop.

Lessons learned

The following lessons can be taken from this incident:

- Just because the work inside the 500m zone had stopped and the vessel could move to a ‘safe’ position outside the 500m zone does not mean that situational awareness can necessarily be relaxed. It was reported that in that location there were several other rigs, shallow water and sand banks. This would typically necessitate adhering to the ASOG as far as reasonably possible or adding to the ASOG. Guidance on operational activity planning (IMCA M220), Chapter 3 discusses CAM and TAM, where TAM is described as:

A TAM is a risk-based operating mode in which the DP vessel may be set up and operated accepting that a failure has the potential to exceed the vessel’s identified worst-case failure. Because of the variances of operational tasks and locations a vessel may have several task appropriate modes. A TAM may be applied where a thorough risk assessment has demonstrated that the consequences of exceeding the vessel’s identified worst-case failure are acceptable”

In this instance exceeding the vessels WCFDI was not acceptable.

- The missing E-Stop Cover – The absence of the E-Stop protection should have been addressed, the purpose of the cover was to prevent such an action inadvertently. This action could have happened at any time whether or not the vessel was engaged in DP operational activities. This was not a malicious action, defects such as these need to be reported as soon as seen and rectified at the earliest opportunity. Experience has shown that an inexpensive plastic cover may save you many hours of anguish.

- The ability of the vessel crew to respond to a blackout situation is crucial, live drills and touch drills along with regular discussions/workshops to familiarise the vessel staff on how to recover the vessel after such failure are essential. The Training & Experience of Key DP Personnel (IMCA M117), gives guidance and expectations of the roles of Vessel Key DP personnel. IMCA regularly publishes examples for DP exercises and drills.

- Contingency – The vessel staff acted in deploying the anchor which did have the effect of holding the vessel from the platform, but it was unknown if there were any subsea structures that could have been damaged due to this action.

- Working/Checking on a single connected generator should be avoided to reduce the likely hood of inadvertent shut-down.

- The IMCA Key DP Personnel CPD App has an extensive learning module for Guidance on operational activity planning (IMCA M220).

- While the deployment of the anchor reduced the vessel’s uncontrolled movement, the report did not discuss the consideration of underwater infrastructure for example, cables, structures and pipelines. It is therefore not clear if the vessel staff were aware or whether this detail was included in an ASOG.

Latest DP incidents

-

Complete the job

Whilst connected to a turbine, an alarm was generated on the DP operator station, ‘Unbalanced load on SWBD 1’.

DPE 01/25

16 January 2025

Undesired event

-

How is your alignment?

Loss of the CyScan position reference system generated a reference system failure alarm and moments later the vessel began to lose position with the accompanying alarms.

DPE 01/25

16 January 2025

Incident

-

Beware your centre of rotation

The stern thrusters started to oscillate which transferred to an oscillating motion of the vessel and high forces were being used to try to maintain position.

DPE 01/25

16 January 2025

Incident

-

A-Tension

Whilst pipelaying in shallow water, the vessel experienced a tension sensor failure on one tensioner.

DPE 01/25

16 January 2025

-

DP Drill Scenario

DP emergency drill scenarios are included to assist DP vessel management, DPOs / Engineers, and ETOs in conducting DP drills onboard.

DPE 01/25

16 January 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.