Follow the ASOG – It’s there for a reason

- DP Event

- Published on 22 December 2023

- Generated on 2 July 2025

- DPE 04/23

- 4 minute read

Incident

Jump to:

A DP vessel was conducting ROV operations beside an oil platform. One of the generators connected to the port switchboard failed and tripped.

Overview

A DP vessel was conducting remotely operated vehicle (ROV) operations beside an oil platform. As this was a Critical Activity Mode (CAM), the vessel was operating a split bus with two generators connected to each switchboard.

One of the generators connected to the port switchboard failed and tripped, there was no effect on vessel station keeping and the remaining connected generator was able to accept the extra load transferred. However, the vessel was operating in a degraded mode and the risk of worst-case failure was greater.

Per the ASOG, the vessel moved to a yellow alert level, the ROV was called back to its Tether Management System (TMS) and the vessel started to move in a controlled manner away from the platform.

Shortly after, and before the vessel left the 500m zone, the port redundant group blacked out, this equalled the Worst Case Failure Design Intent (WCFDI).

Operational setup

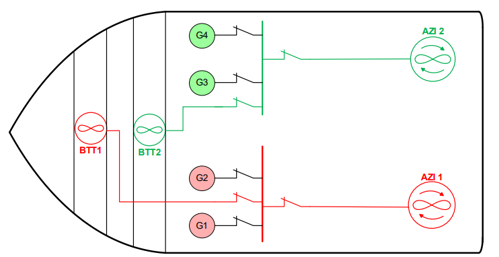

Vessel configuration: The vessel was operating in a split bus configuration, a standard practice in DP operations to enhance electrical redundancy and reliability. This set-up involved two generators connected to separate switchboards (port and starboard).

Figure: Power Configuration Prior to Event

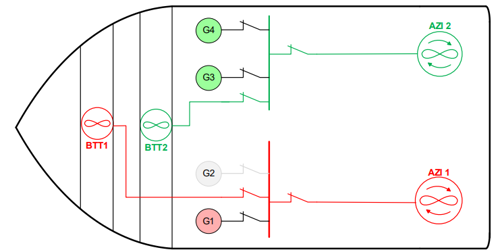

Figure: Power Configuration Following Initial Failure of G2

The primary operation involved ROV deployment for subsea tasks adjacent to the oil platform, classified as a Critical Activity Mode (CAM) due to the proximity to the platform and the nature of the operations.

Incident overview

Initial Generator Failure: During operations, one of the generators connected to the port switchboard experienced a failure and subsequent trip. This incident posed a potential risk to the vessel’s DP capability and, by extension, to the ROV operations and the nearby oil platform.

Immediate Response and System Resilience: The vessel’s DP system demonstrated resilience through redundancy. The remaining generator on the port switchboard successfully accepted the additional load, ensuring no immediate impact on the vessel’s station-keeping ability.

Procedural Response: Shift to Yellow Level: In accordance with the Activity Specific Operating Guidelines (ASOG), the vessel’s operational status was changed to a ‘yellow level’. This change in status indicated a heightened awareness and a move towards conservative operational measures.

ROV Recall: As a precaution, the ROV was ordered to return to its TMS, signalling a temporary halt to subsea operations.

Vessel Repositioning: The vessel commenced manoeuvres to move away from the oil platform, reducing the risk of any potential impact due to the compromised redundancy in its power generation and distribution system.

Secondary Incident: Port Redundant Group Blackout: In a subsequent development, the port redundant group experienced a complete blackout. This incident occurred before the vessel exited the 500m safety zone around the platform.

Worst Case Failure Design Intent (WCFDI): The partial blackout represented a scenario equivalent to the WCFDI, a critical threshold in DP operations. This scenario envisages the most severe failure the DP system is designed to withstand while maintaining position.

What happened?

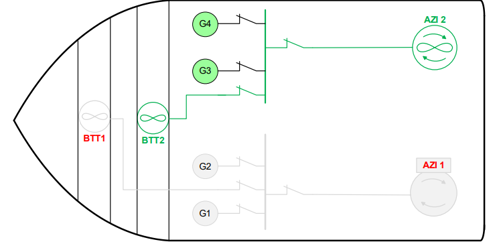

After the generator failed, the vessel technical staff initiated the fault-finding process and, or so they believed, discovered the issue without delay. They attempted to reconnect the generator after incorrectly concluding that they had identified the problem – however, doing so resulted in a voltage spike on the main switchboard, which subsequently caused a complete blackout of that switchboard.

Figure: Power configuration after attempting to re-connect G2

Conclusion

This incident underscores the importance of robust DP system design and the efficacy of procedural responses in managing unexpected failures. Key takeaways include:

- The impact of attaining a Yellow alert status in the ASOG was defeated when the technical staff of the vessel bypassed the ASOG and re-established the generator connection. It was unequivocally stated by the ASOG that machinery should not be reinstated until the vessel was in a safe position or status, which effectively meant being outside the 500m zone.

- System resilience: The ability of the remaining generator to assume additional load highlights the importance of designing DP systems with adequate redundancy and load-sharing capabilities, and, operating the DP system within its designed capability.

- Need for continuous monitoring: Continuous monitoring and regular maintenance of all critical systems, especially power generation and distribution in DP vessels, are essential to prevent such incidents.

- Training and preparedness: Regular training and drills for vessel crews on managing such emergencies are crucial for ensuring safety during critical operations like ROV deployment near oil platforms.

- Effective emergency protocols – ASOG: The swift transition to a yellow alert level and the immediate recall of the ROV demonstrate the vessel crew’s adherence to ASOG and their preparedness to respond to emergencies.

Latest DP incidents

-

Complete the job

Whilst connected to a turbine, an alarm was generated on the DP operator station, ‘Unbalanced load on SWBD 1’.

DPE 01/25

16 January 2025

Undesired event

-

How is your alignment?

Loss of the CyScan position reference system generated a reference system failure alarm and moments later the vessel began to lose position with the accompanying alarms.

DPE 01/25

16 January 2025

Incident

-

Beware your centre of rotation

The stern thrusters started to oscillate which transferred to an oscillating motion of the vessel and high forces were being used to try to maintain position.

DPE 01/25

16 January 2025

Incident

-

A-Tension

Whilst pipelaying in shallow water, the vessel experienced a tension sensor failure on one tensioner.

DPE 01/25

16 January 2025

-

DP Drill Scenario

DP emergency drill scenarios are included to assist DP vessel management, DPOs / Engineers, and ETOs in conducting DP drills onboard.

DPE 01/25

16 January 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.