Inadequate shallow water lay-up reactivation procedures

- DP Event

- Published on 30 November 2018

- Generated on 21 February 2026

- DPE 04/18

- 1 minute read

Undesired event

Jump to:

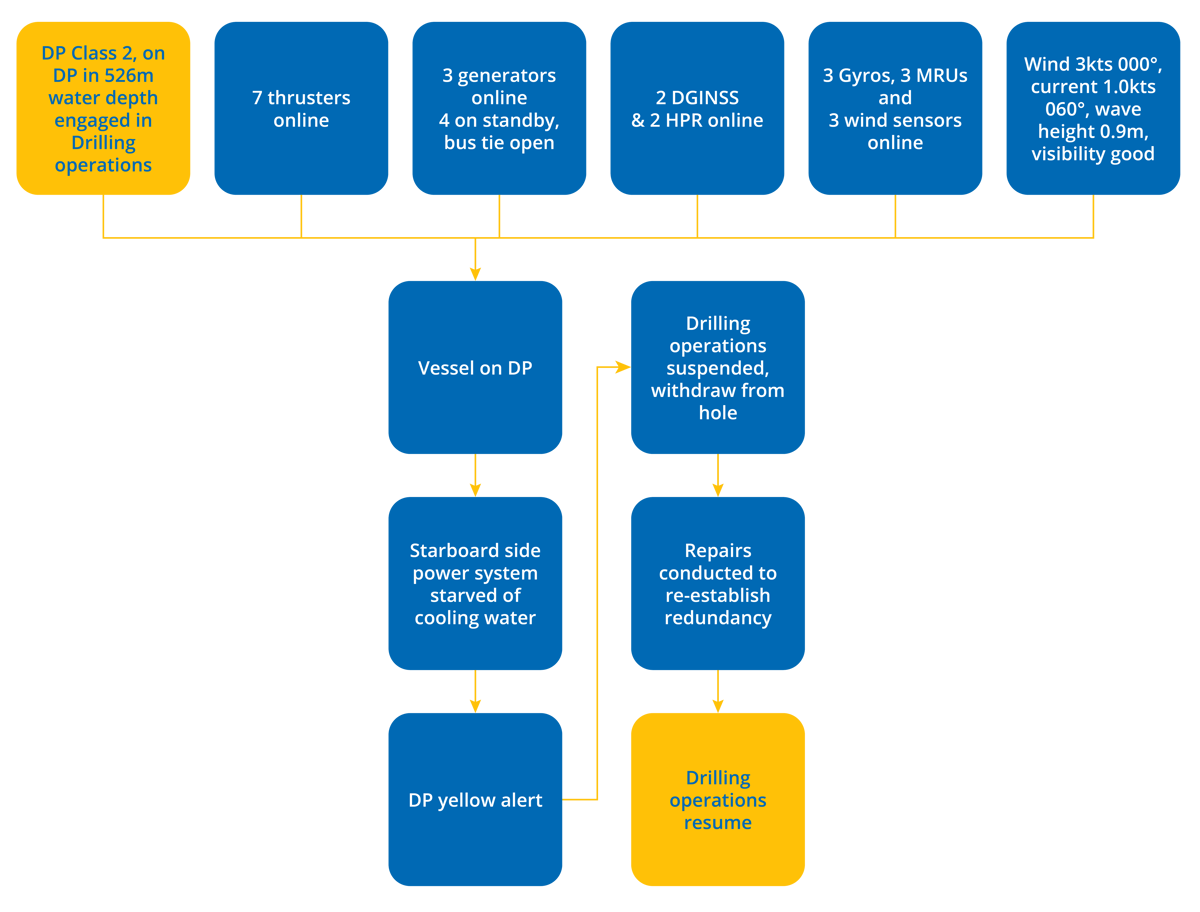

The heat exchange system was poorly designed, without redundancy for half the switchboard. This was compounded by turbidity and silt in the cooling system.

Comments

The heat exchange system is poorly designed and without redundancy for half of the switchboard. Design flaws were compounded by the introduction of turbidity and silt into the cooling system.

The vessel was idle for some time in shallow water and the systems were not adequately preserved.

There was biological fouling taking place on the heat exchangers. Although multiple heat exchanger cleanings had occurred, the system was not adequately flushed to remove the fouling.

Considerations

- The report indicates that although the cooling systems were cleaned prior to reactivation they had not been properly flushed and were therefore unable to perform to full capacity.

- It is important that all redundant systems are able to perform to full capacity following loss of a redundant group. If not, there is a potential to exceed the WCFDI following a failure.

- Performance tests should be part of the reactivation procedures after an idle period in shallow water.

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.