Lack of maintenance caused a problem involving the bus tie breaker

- DP Event

- Published on 27 February 2018

- Generated on 21 February 2026

- DPE 01/18

- 2 minute read

Undesired event

Jump to:

The maintenance requirements of some major DP components were not included in the vessel's computerised Planned Maintenance System.

Comments

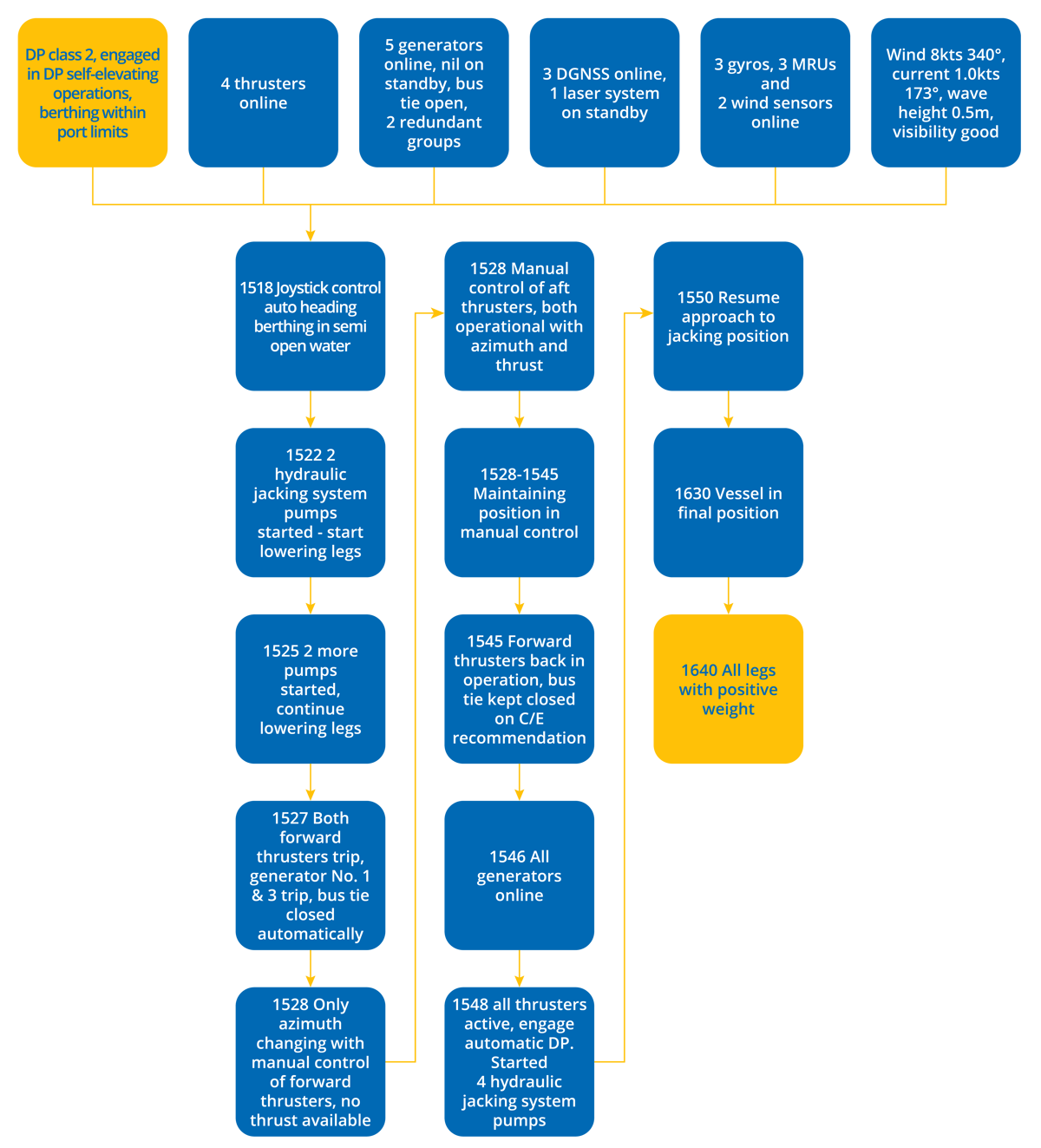

The power management system was set for semi-automatic mode as required for DP2 operations.

Uncontrolled and unsynchronised closure of the bus tie breaker resulted in simultaneous trip of DG1 and DG3 with a consequence that the forward thrusters tripped.

Based on conclusions from the technical analysis, the primary reason (root cause) of the event had been identified as lack of maintenance of the DP critical system(s) more precisely the bus tie breaker.

The ship was provided with a computerised planned maintenance system (PMS) which should cover all maintenance activity on board. The maintenance requirements of some major DP components were not included in the PMS.

Considerations

- From the information supplied, there was minimal DP stabilisation period allowed for at the start of the operation or following recovery when the vessel again engaged DP control.

- It took 18 minutes to restore both forward thrusters – could this have been achieved more quickly?

- It is assumed that a partial blackout occurred, causing loss of both forward thrusters – normally the thrusters would be arranged such that the worst case failure (WCF) would cause the loss of one forward and one aft thruster.

- It appears that the control of the thrusters was taken manually, however it should be questioned whether the automatic DP system or JSAH would have maintained the vessel in position.

- While post-failure recovery time is definitely an issue, it seems that vessel design and operating configuration could be the root causes.

- The event does highlight the importance of identifying and maintaining all items of critical operational equipment.

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.