Separate problem with two thrusters caused loss of DP

- DP Event

- Published on 13 September 2016

- Generated on 21 February 2026

- DPE 03/16

- 1 minute read

Incident

Jump to:

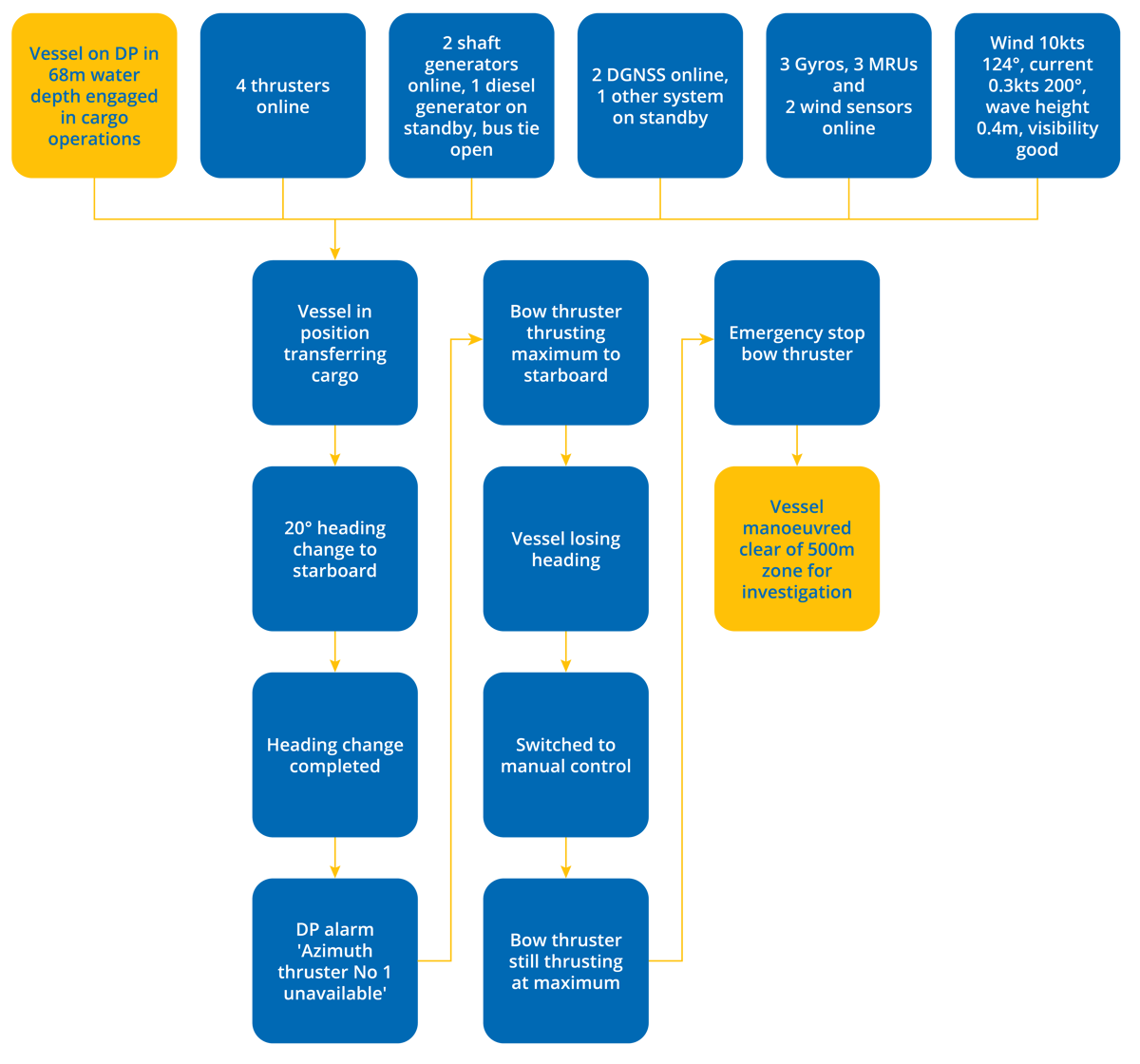

The seat for the stop solenoid on the engine was damaged causing a slight air leak causing a reduction in main engine rpm.

Comments

The bow thruster gave an alarm that pitch was at maximum showing 114% on DP display. Investigation concluded that the full starboard maximum limit command/set point of the bow thruster proportional valve had been adjusted to 70%. During maximum pitch request the valve had to be permanently opened with constant and continuous hydraulic oil flow through the proportional valve.

It was concluded that because the valve direction flow was set at 70% this resulted in the valve’s malfunction and pitch stuck at maximum. It was later discovered that the azimuth thruster tripped because of sea water contamination of the gear box oil.

Considerations

- Consideration should always be given to making heading changes in incremental steps, a heading change of 20° in one step during critical operations is not recommended.

- To stop adverse thrust from a rogue thruster it must be shut down and not just deselected from DP control.

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.